Anti-uplift retreating deep hole grouting system and method for crossing existing shield tunnels

A shield tunneling and retreating technology, applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problem of easy uplift of soil and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

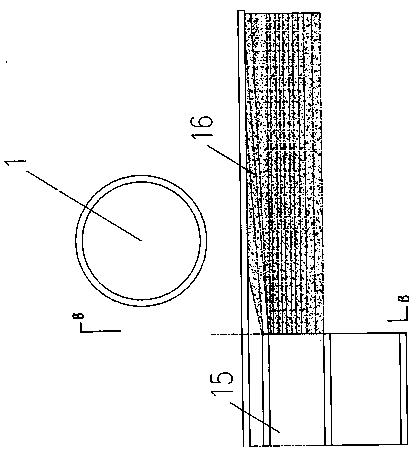

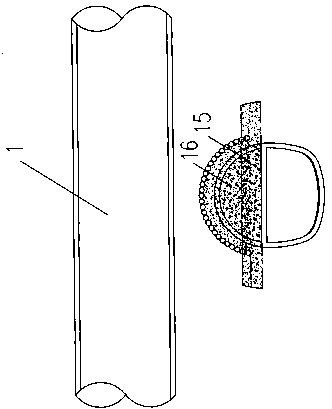

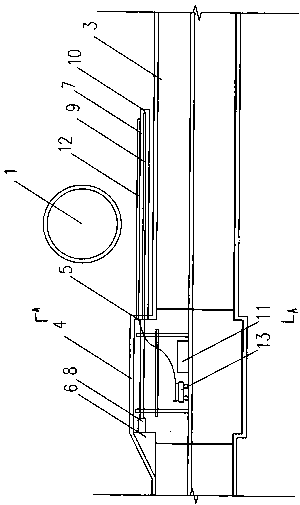

[0024] An anti-uplift retreating deep hole grouting system for crossing an existing shield tunnel, comprising an existing shield tunnel 1, under which a pre-excavated underground excavation section tunnel is arranged. 3. At the left end of the section tunnel 3 under the pre-excavated mine method underground excavation, the excavated section civil air defense section tunnel 4 is arranged, and the pre-excavated mine method underground tunnel 4 in the excavated section civil air defense section tunnel 4 is arranged. The upper guide hole face 15 of the section tunnel 3 dug down is densely covered with deep hole grouting holes 16, and the distance between adjacent deep hole grouting holes 16 is 20-30 cm. The drill pipe and the grouting casing of the retreating deep hole grouting machine are set, the grouting pressure of the retreating deep hole grouting machine is 1-1.5 MPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com