Zero-emission filling device for cryogenic liquid tank car and filling method of zero-emission filling device

A low-temperature liquid, zero-discharge technology, which is applied in container discharge methods, container filling methods, gas/liquid distribution and storage, etc., can solve the problems of increased liquid sales and transportation costs, waste, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

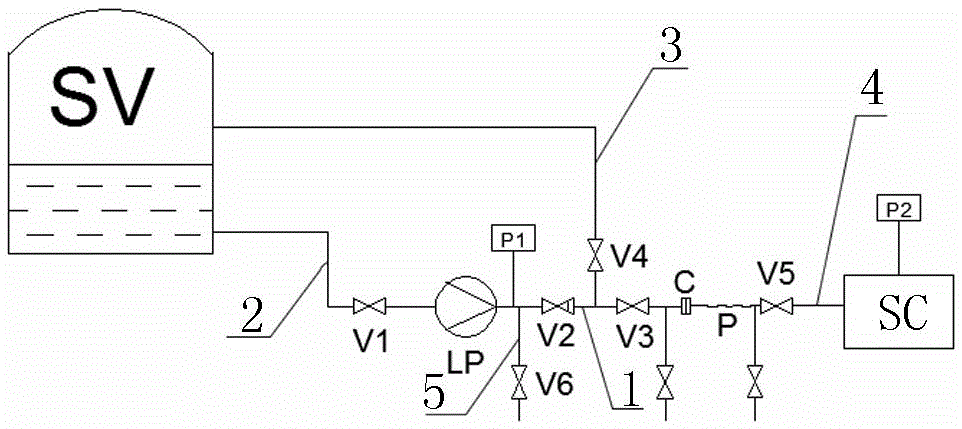

[0022] Embodiment: In the present invention, there is a return pipe at the outlet of the cryogenic liquid pump leading to the storage tank. The liquid in the storage tank flows into the cryogenic liquid pump, and then flows back to the storage tank through the return pipe at the outlet of the cryogenic liquid pump. After confirming that the cryogenic liquid pump is completely pre-cooled, Start the cryogenic liquid pump, control the pressure of the pump through the return valve on the return pipe to be 2-3bar higher than the pressure of the tank car, and then open the tank car inlet valve to fill the tank car with liquid, and the pressure in the tank car will gradually decrease significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com