Composite rotary kiln sealing device

A sealing device and rotary kiln technology, which is applied to rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of not being able to adapt to the large-diameter radial runout of rotary kilns, and achieve simple structure, good airtightness, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

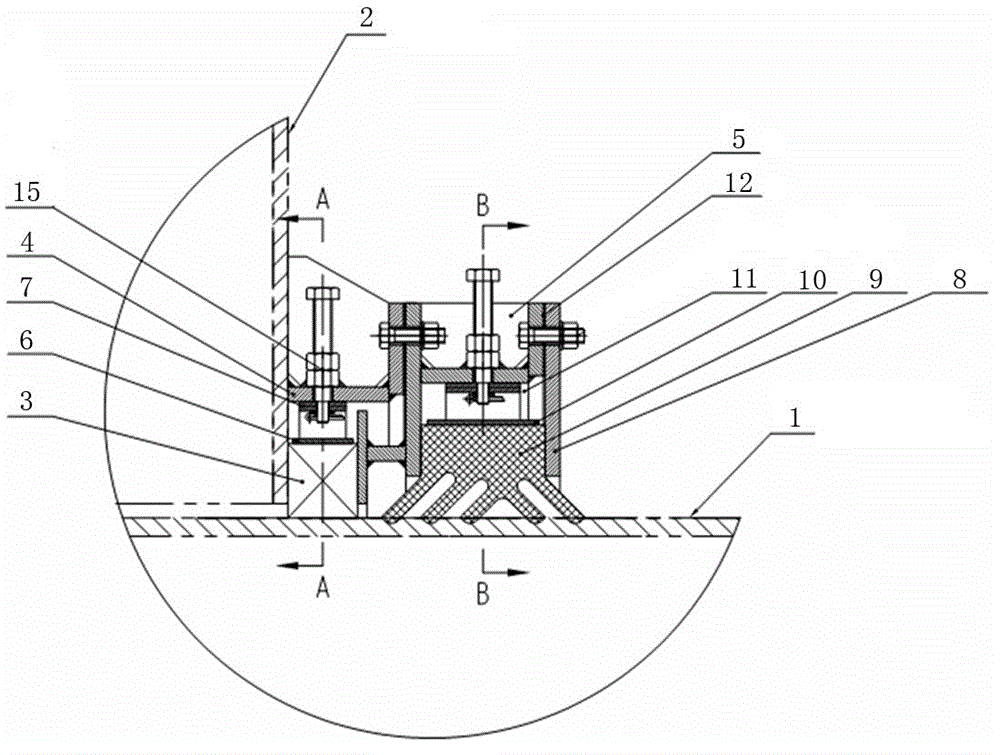

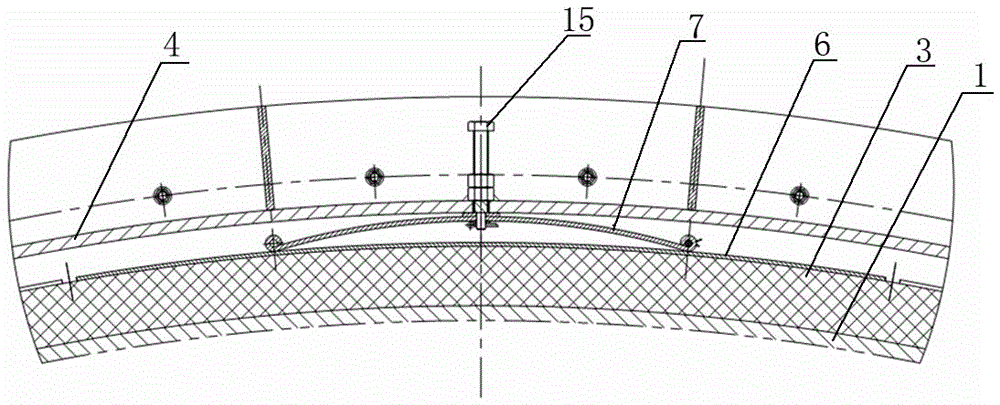

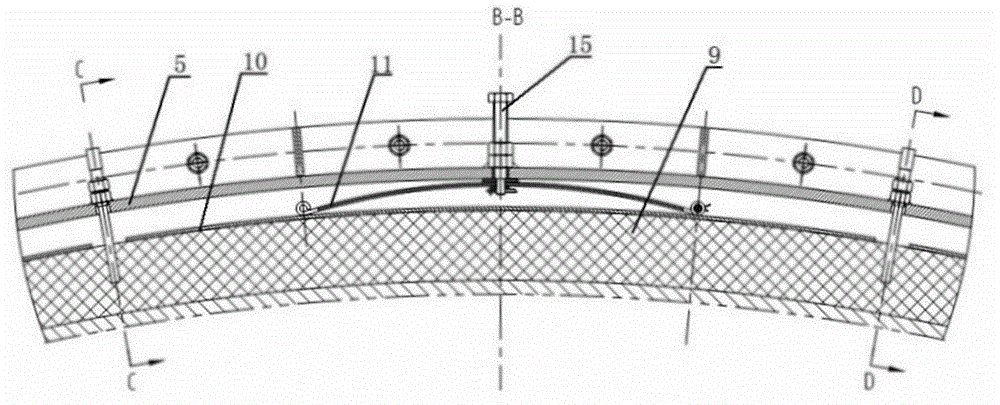

[0019] As shown in the figure, a composite rotary kiln sealing device includes a packing 3 wound around the connection between the rotary cylinder 1 and the outer wall 2 of the cover, and the upper end surface and the outer end surface of the packing 3 respectively pass through the sealing seat The ring I4 and the sealing seat ring Ⅱ5 are pressed tightly. A pressing plate I6 is arranged between the sealing seat ring I4 and the upper end surface of the packing 3, and an arc-shaped leaf spring I7 is arranged in the annular cavity between the pressing plate I6 and the sealing seat ring I4. The middle part of the leaf spring I7 is fixed on the sealing seat ring I4, the two ends of the leaf spring I7 are pressed on the pressure plate I6; the sealing seat ring II5 is pressed against the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com