Magnetic field detection method for detection of key parameters of submerged arc furnace smelting

A key parameter and submerged arc furnace technology, which is applied in the field of magnetic field detection method and key parameter detection of submerged arc furnace smelting, can solve the problem that key parameters cannot be effectively measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] With reference to the drawings, the present invention will be further described in detail.

[0021] A new method for detecting key parameters of submerged arc furnace smelting—magnetic field detection method, including the following steps:

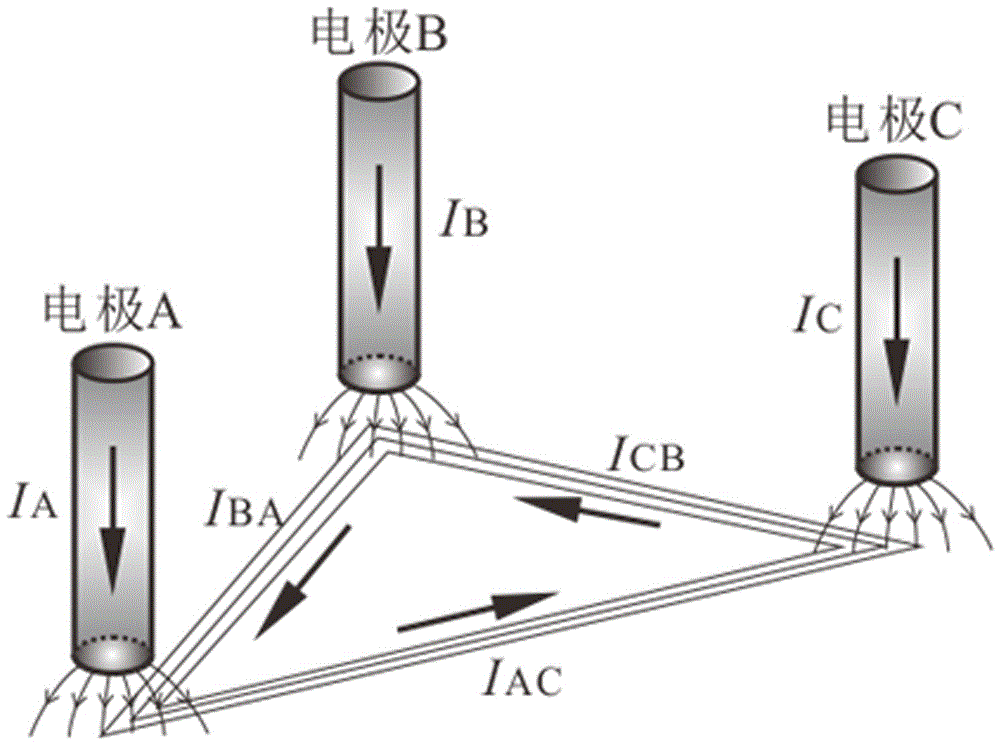

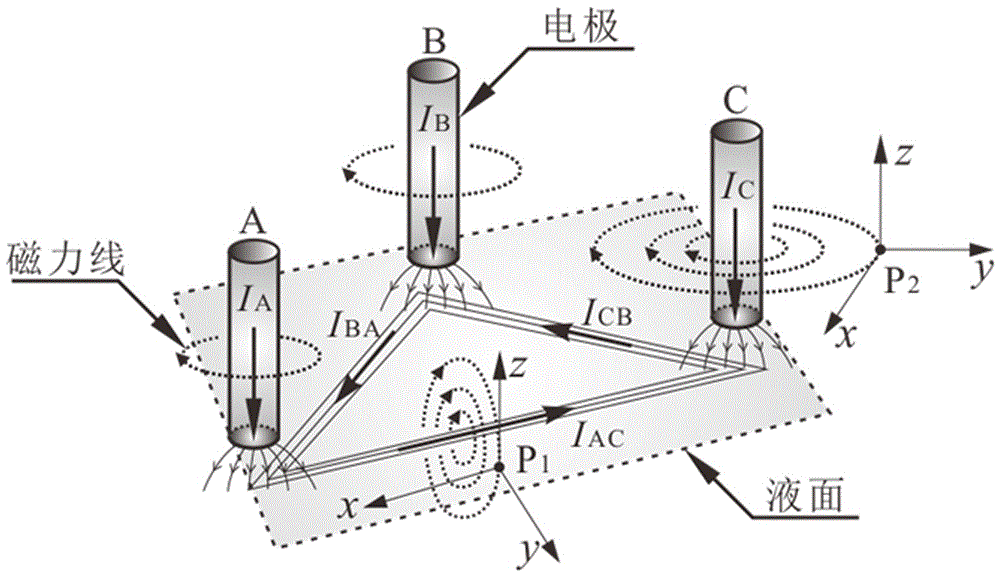

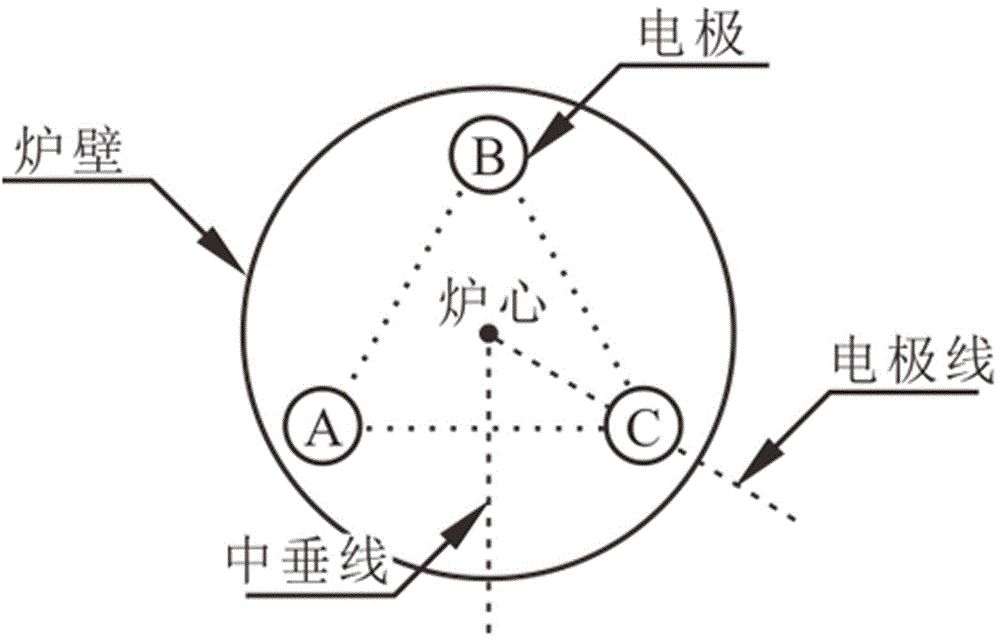

[0022] Step 1: In the furnace of the submerged arc furnace, a strong current enters the furnace through the electrodes, forming a current loop on the surface of the molten pool. Take the triangular current loop as an example to establish the furnace circuit model, such as figure 1 As shown, the current flowing through the electrodes in the furnace is the electrode current I A , I B , I C , Electrode current I A , I B , I C It reaches the molten pool through the arc zone, forming a triangular molten pool current loop near the molten pool liquid level, I AC , I CB , I BA Respectively the molten pool current.

[0023] According to Biot-Savart law, any current element on any current loop The point is called the source point, and the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com