Ultrasonic flaw detection method for identifying hollow-bead defect of submerged arc welded pipe

A technology of submerged arc welded pipe and ultrasonic wave, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., which can solve the problems of low detection efficiency, inability to effectively guarantee the quality of submerged arc welded pipe finished products, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] The ultrasonic flaw detection method for identifying submerged arc welded pipe bead defects of the present invention specifically includes the following steps:

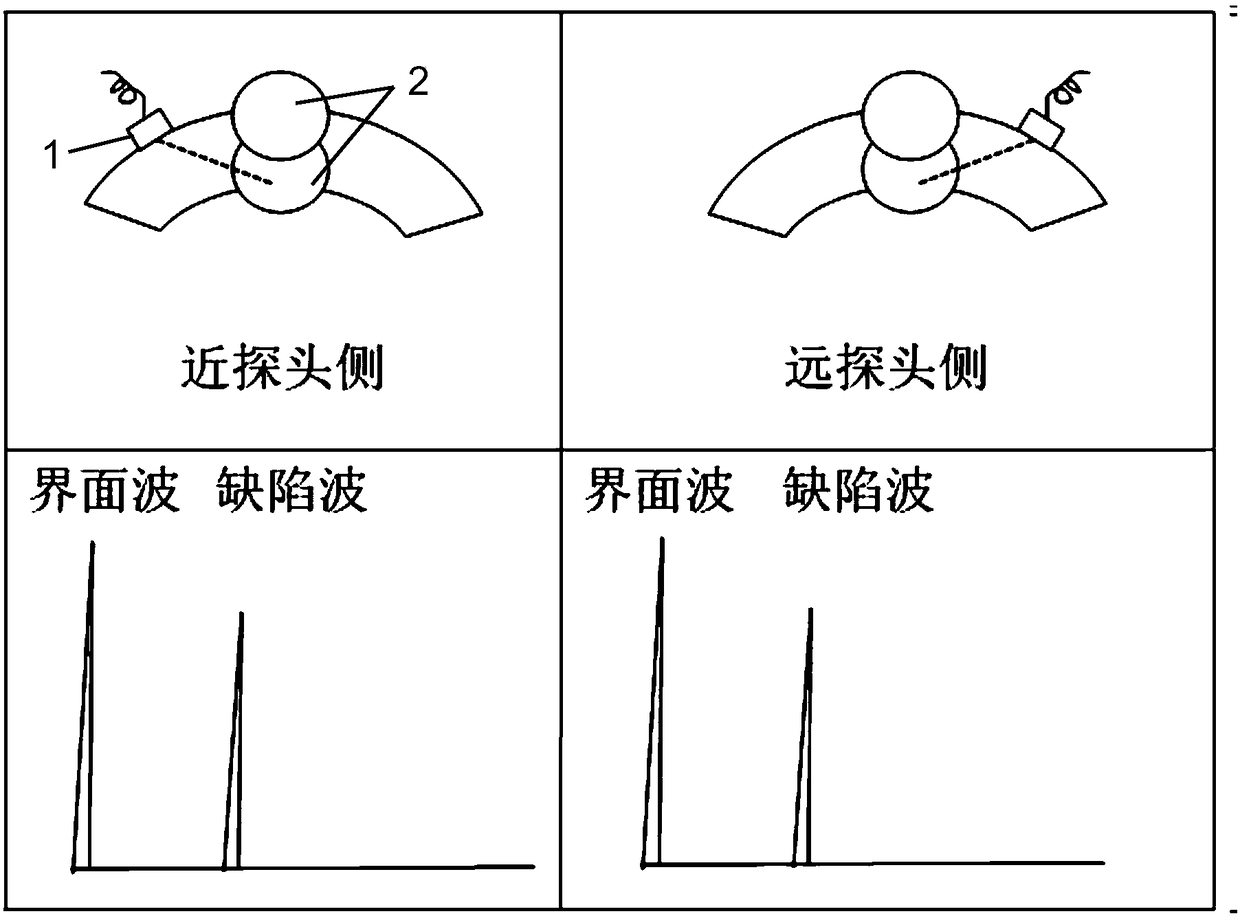

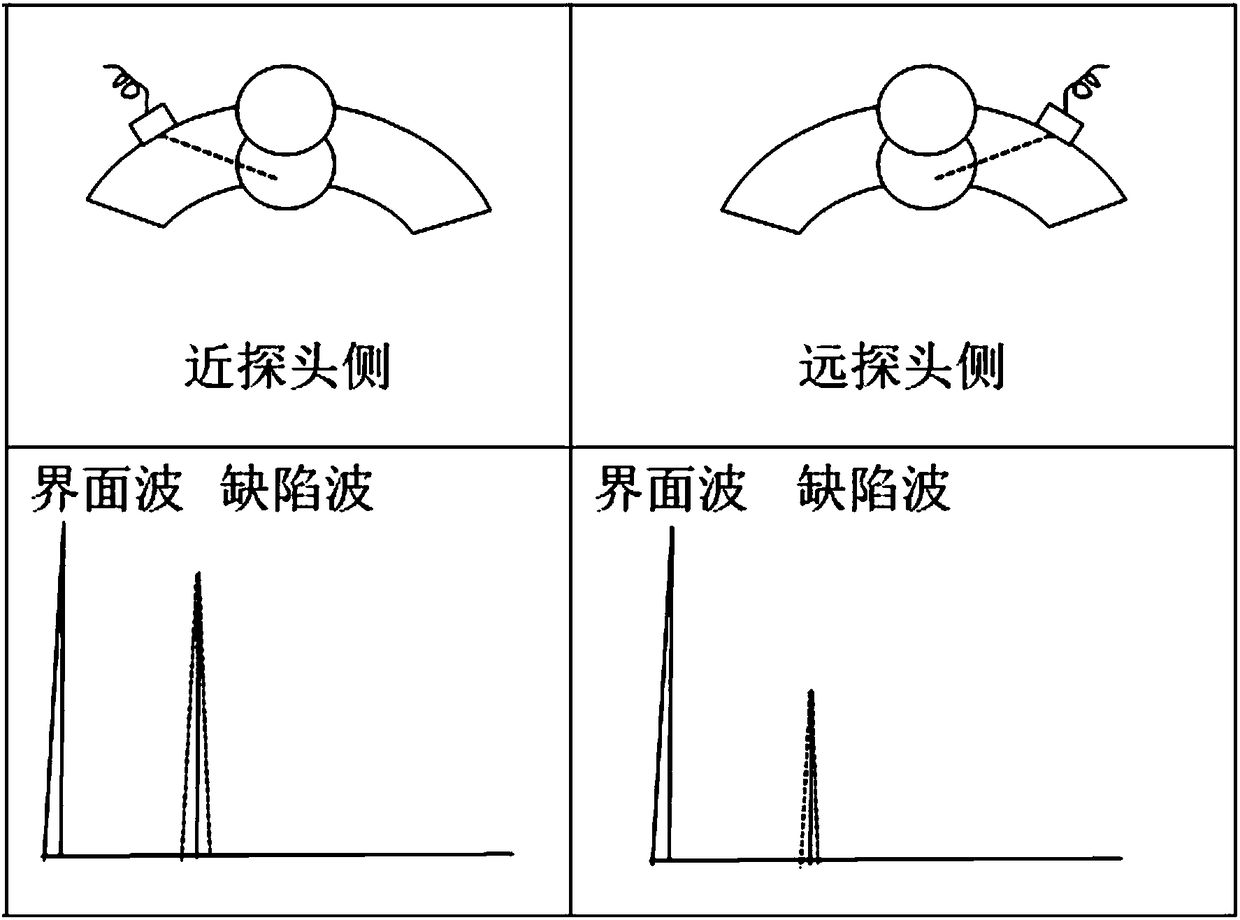

[0035] Step A. Through the weld bead, air hole and other volume-shaped defects such as bead defects, detect on both sides of the weld at an equidistant distance of 45°, and carry out step-by-step identification according to different shear wave reflection characteristics. First, distinguish the bead Beads, porosity, and other imperfections.

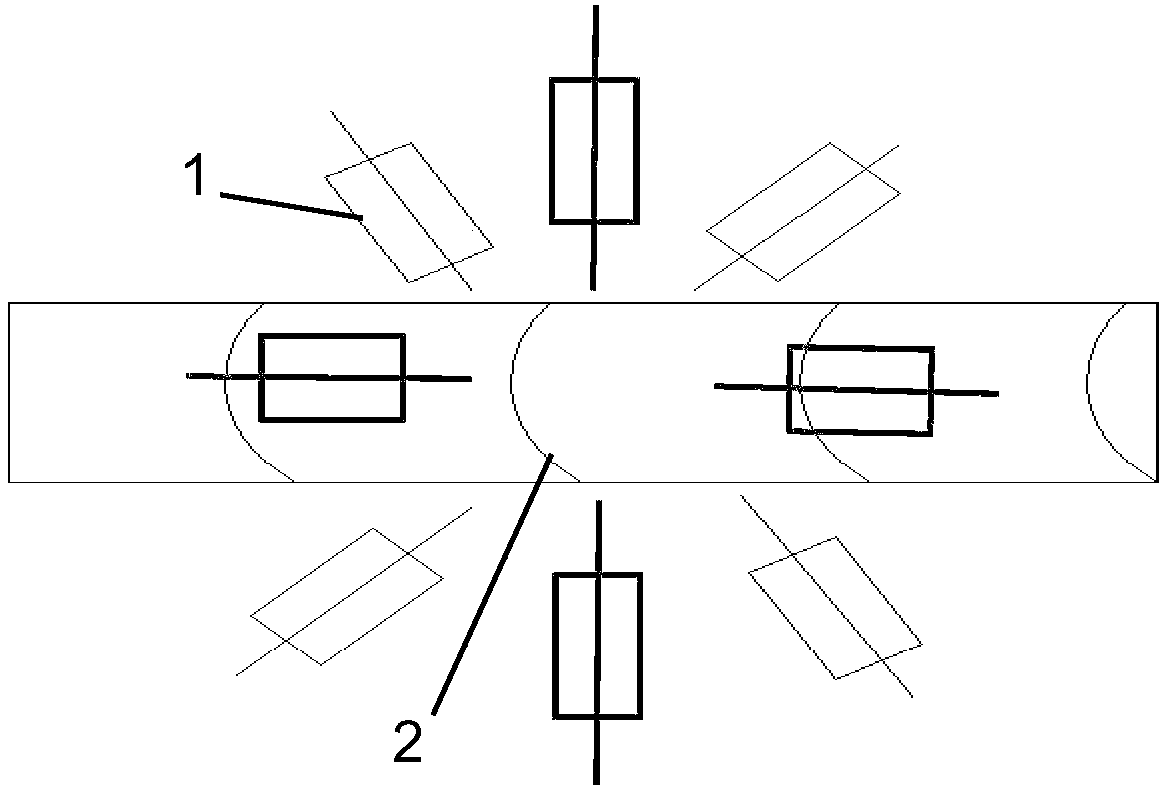

[0036] Specific as figure 1 As shown, first place the shear wave probe 1 (the shear wave probe 1 described below is a conventional shear wave probe) on the side of the weld 2 for detection, if there is an echo in the weld 2, that is, the echo is obvious There are 2 to 3 defect waves with low amplitude before and after the defect wave, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com