Automatic efficient drawing force testing device

A testing device, high-efficiency pulling technology, applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problems of consuming staff, complicated testing, inflexible operation, etc., and achieve simple structure of the device, The effect of improving test efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

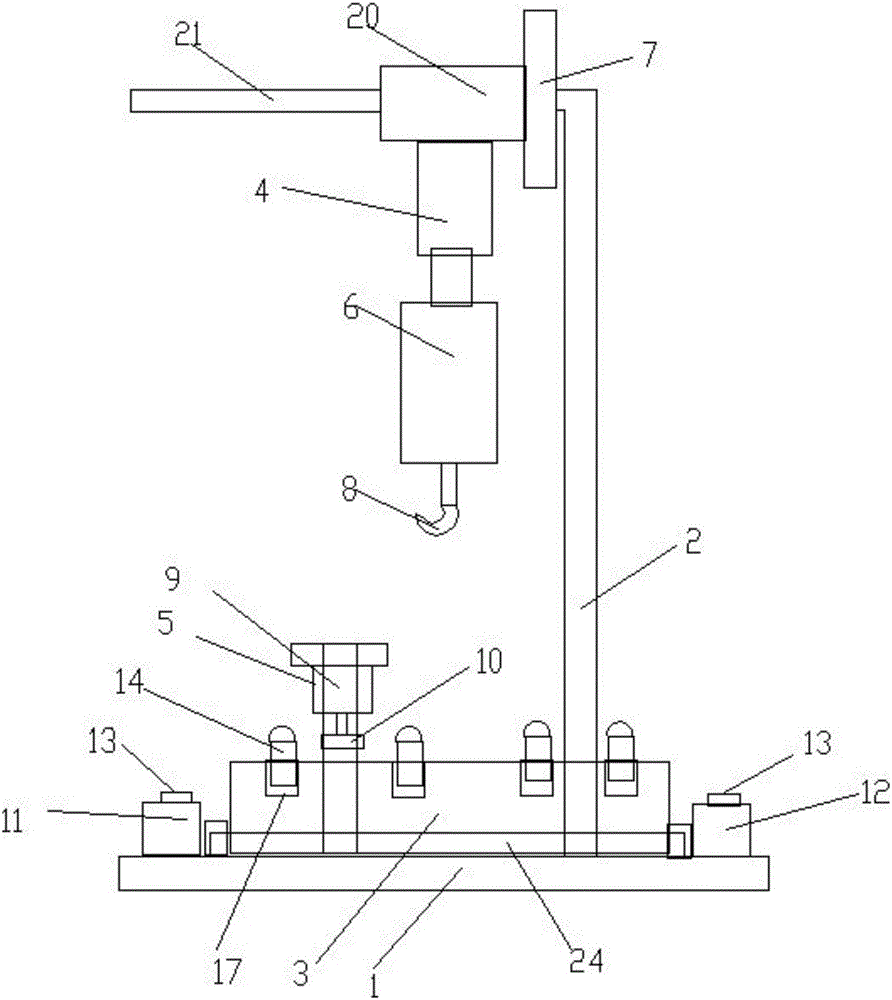

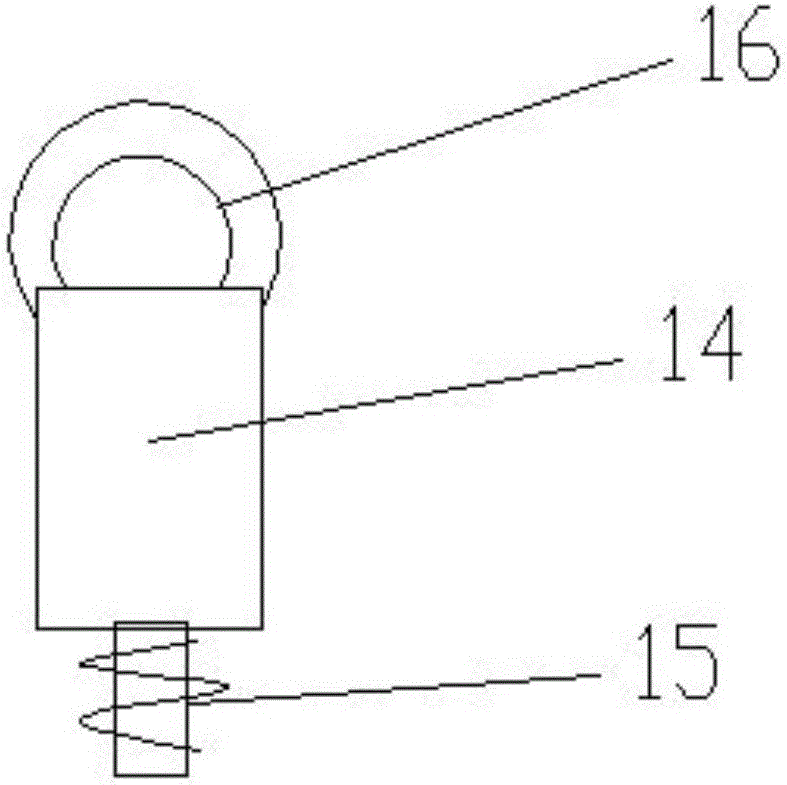

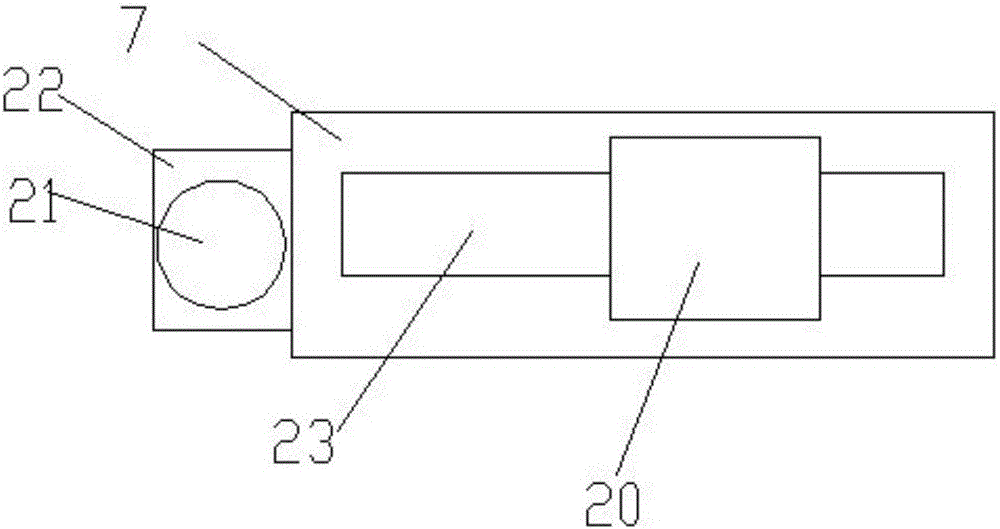

[0028] Embodiment:. An automatic high-efficiency pull-out force testing device, comprising workbench 1, fixed rod 2, beam 7, slide block 20, positioning block 3, lifting cylinder 4, compression cylinder 5 and tension gauge 6, described fixed The rod is vertically fixed on the workbench, the fixed rod is in an inverted L-shape, the beam moves left and right and is connected to the L-shaped straight part of the fixed rod, and the slider slides back and forth and is horizontally connected to the beam side of

[0029] The lifting cylinder is vertically fixed on the lower end of the slider, the tension gauge is vertically fixed on the head of the lifting cylinder, the lower end of the tension gauge is fixedly connected with a hook 8, and the positioning block is freely placed on the on said workbench;

[0030] A ball screw 24 is horizontally installed on the workbench, and the left and right movement of the ball screw is provided with a ball bearing 25, and also includes a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com