Composite insulator interface detection method

A technology of composite insulators and detection methods, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effect of improving accuracy and prolonging the boiling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

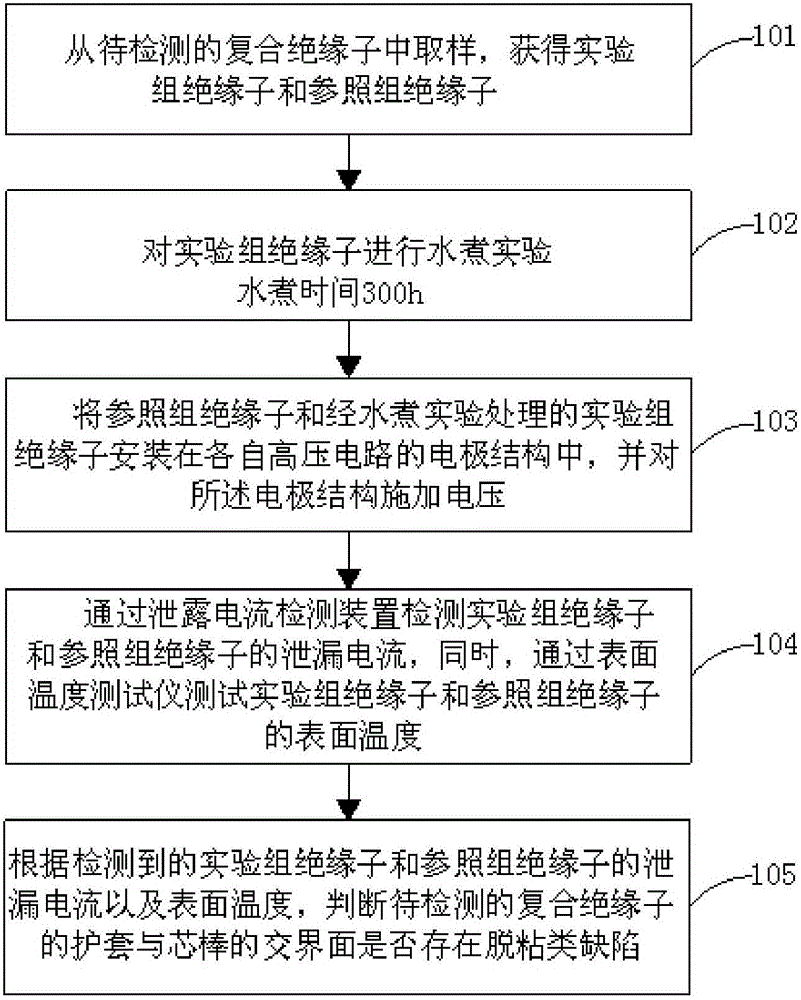

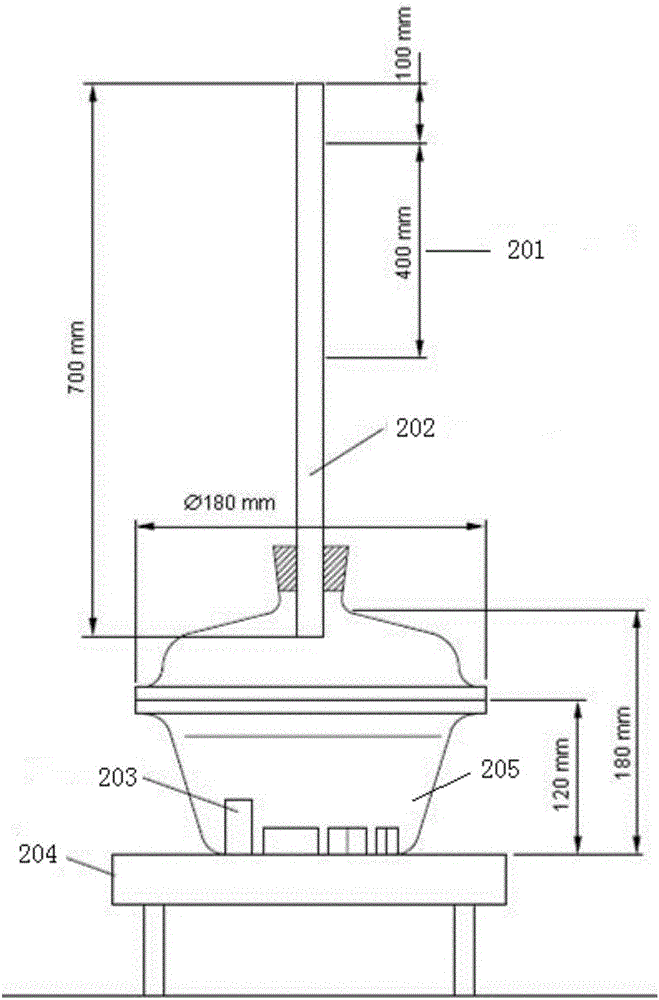

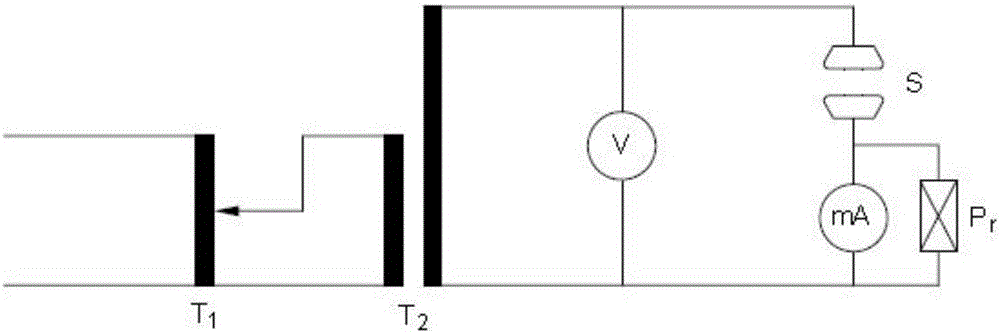

[0034] There are many defects at the interface of composite insulators, but there is no specific detection method for the debonding defect at the interface between the sheath and the mandrel, that is, the defect of the bonding quality at the interface between the sheath and the mandrel. The invention provides a method for detecting debonding defects at the interface between the sheath and mandrel of a composite insulator. During the experiment, the debonding defects will become more obvious, there will be moisture intrusion in the defect, and the conductivity of the material will increase. At this time, a gradually rising voltage is applied to the composite insulator, and the current density at the defect will increase. Then the leakage current will increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com