A low-power rectifier component using ball planting technology and its manufacturing method

A manufacturing method and component technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of difficult processing, high cost of production raw materials, unstable quality, etc., and achieve good electrical and thermal conductivity , Reduce the cost of raw materials and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

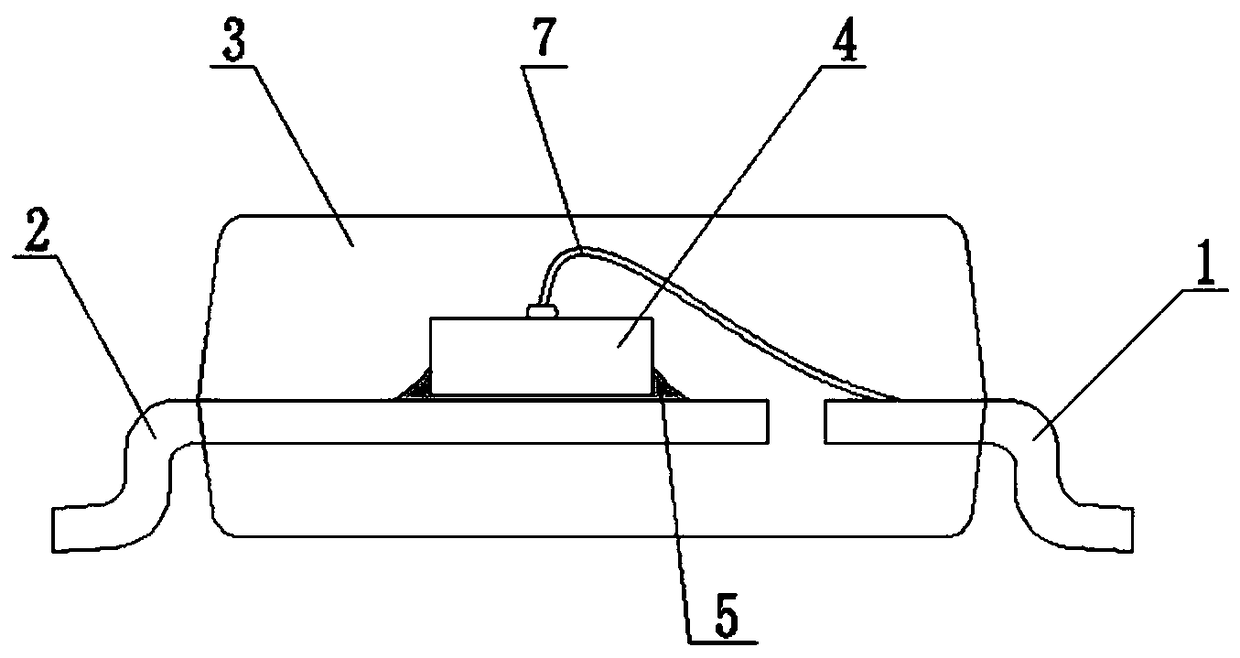

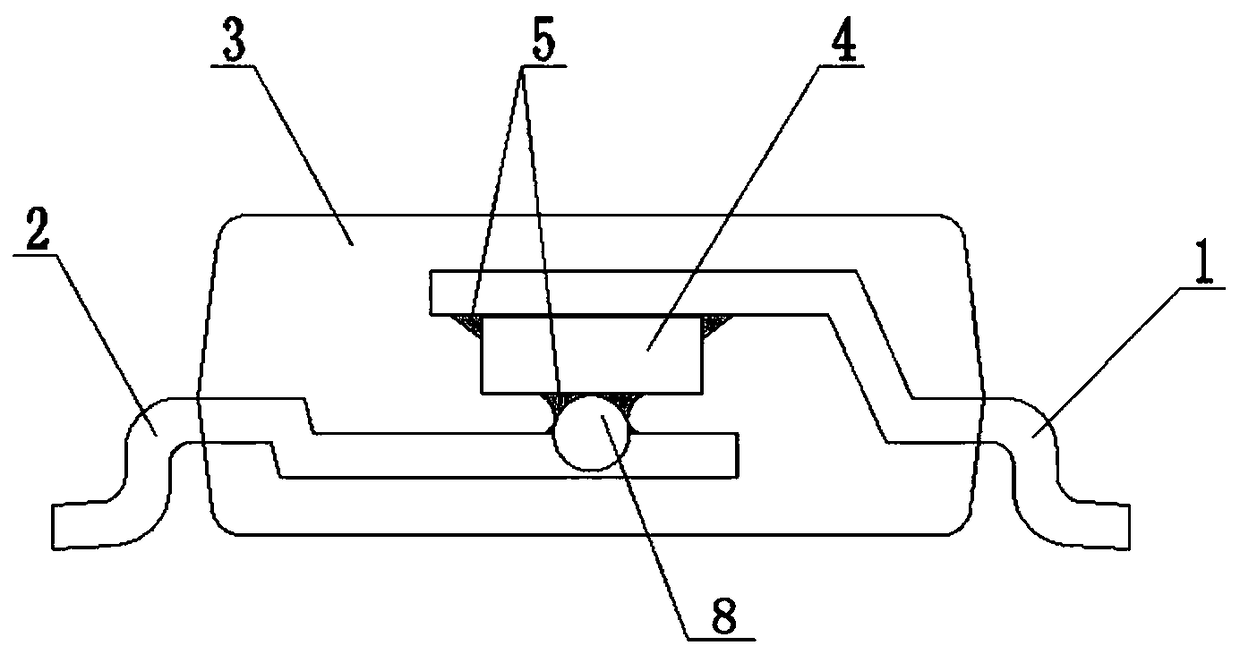

[0038] Such as image 3 As shown, the present invention adopts the low-power rectifying components of the ball planting process, including a plastic-encapsulated epoxy resin 3, which is provided with a lead frame A 1 and a lead frame B 2 located below the lead frame A; the lead frame A The lower surface of 1 is welded with chip 4 and the positive electrode of the chip is facing downward. On the upper surface of lead frame B 2 and corresponding to the position of the chip, a spherical crown pit or through hole 22 is set to fix the conductive ball 8. The conductive ball 8 and the chip 4 The positive poles are in contact to form a current path.

Embodiment 2

[0040] A kind of manufacturing method of low-power rectifying component and parts as described in embodiment 1, comprises steps as follows:

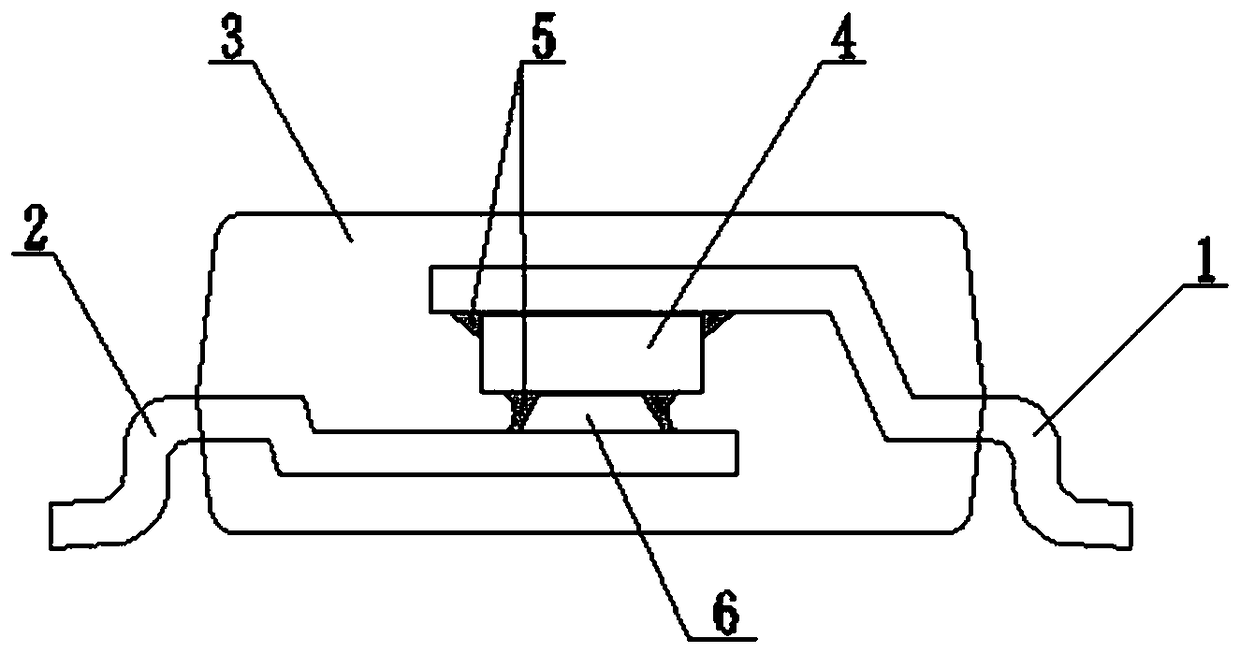

[0041] S1, fixing the chip: Dip and coat solder 5 on the chip welding surface 11 where all lead frames A 1 and the chip are welded, such as Figure 4 As shown, the solder 5 adopts solder paste; the chip 4 is placed on the chip soldering surface 11 coated with solder, with the positive electrode of the chip facing up, as Figure 5 As shown, the chip 4 is fixed on the lead frame A1.

[0042] S2, ball planting:

[0043] Before planting the ball, process the ball crown pit or through hole 22 on the conductive ball soldering surface 21 of the lead frame B2 to fix the conductive ball, such as Figure 7 shown;

[0044] On the conductive ball soldering surface 21 of all lead frames B 2, dip and coat solder 5 or flux, such as Figure 6 As shown, the solder 5 adopts solder paste;

[0045] Manufacture a stencil matching the lead frame B2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com