High voltage jfet device and process method

A process method and device technology, applied in the field of high-voltage JFET devices, can solve problems such as concentration drop, and achieve the effects of reducing pinch-off voltage, simple implementation, and improving breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

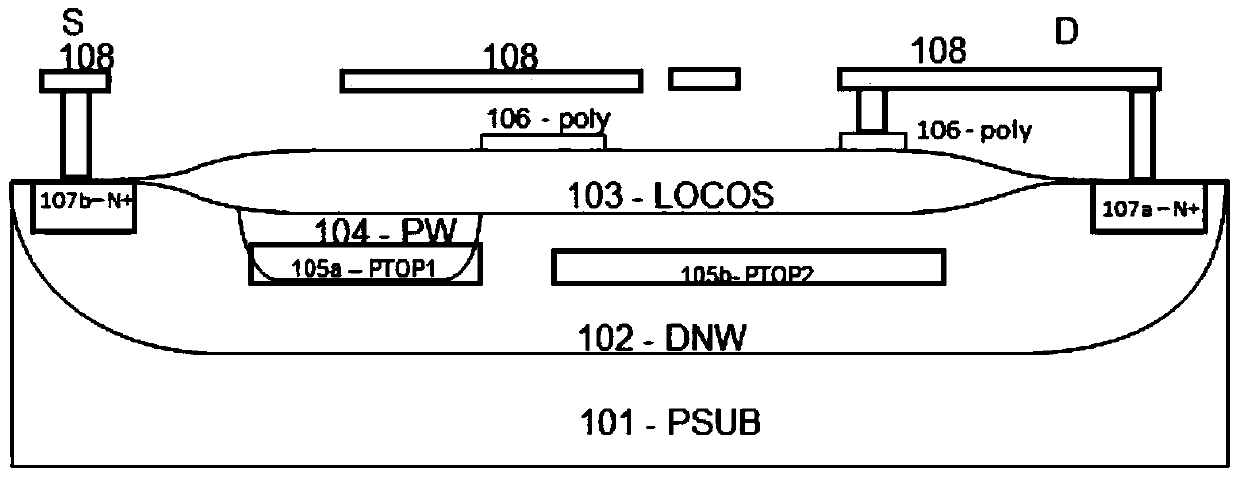

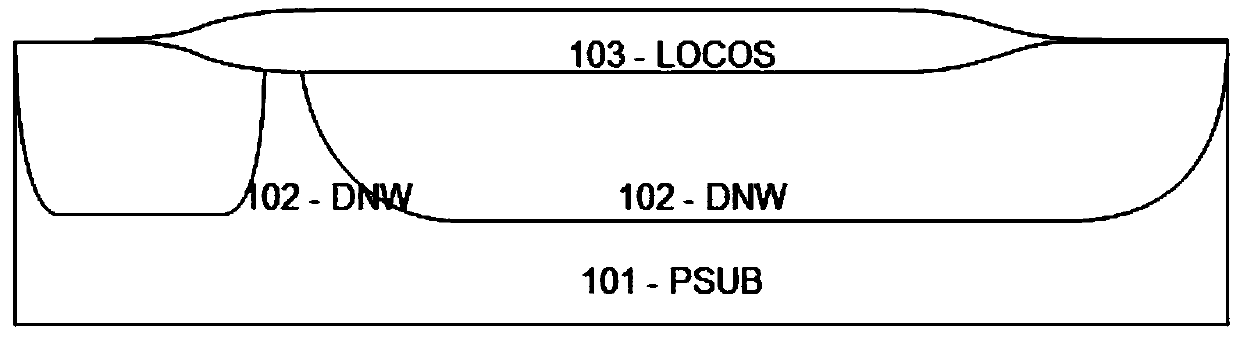

[0026] High voltage JFET device described in the present invention, such as Figure 8 As shown, there is an N-type deep well 102 in the P-type substrate 101. From the cross-sectional perspective, the field oxygen 103 is above the N-type deep well 102, and the two ends of the field oxygen 103 are the source region 107b and the drain region of the JFET respectively. 107 a , the field oxygen 103 covers the polysilicon field plate 106 .

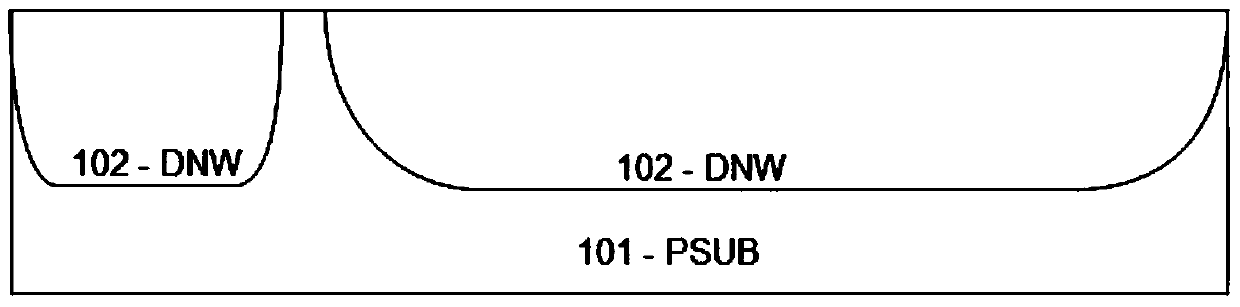

[0027] The N-type deep well 102 is divided into two sections, the first N-type deep well and the second N-type deep well, such as Figure 8 As shown in , the first N-type deep well 102 on the left side includes the source region 107b of the JFET, and the second N-type deep well 102 on the right side includes the drain region 107a of the JFET and the P-type injection layer 105b; the first The N-type deep well and the second N-type deep well are independent of each other, with a certain distance between them, generally 2-6 μm, and the distance can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com