Hexagonal Terminal Forming Mold

A technology for forming molds and moulds, which is applied in the direction of electrical components, circuits, connections, etc., can solve the problems that the wiring harness is difficult to meet the standard, and achieve the effects of not easy to loosen, high precision, and compact crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

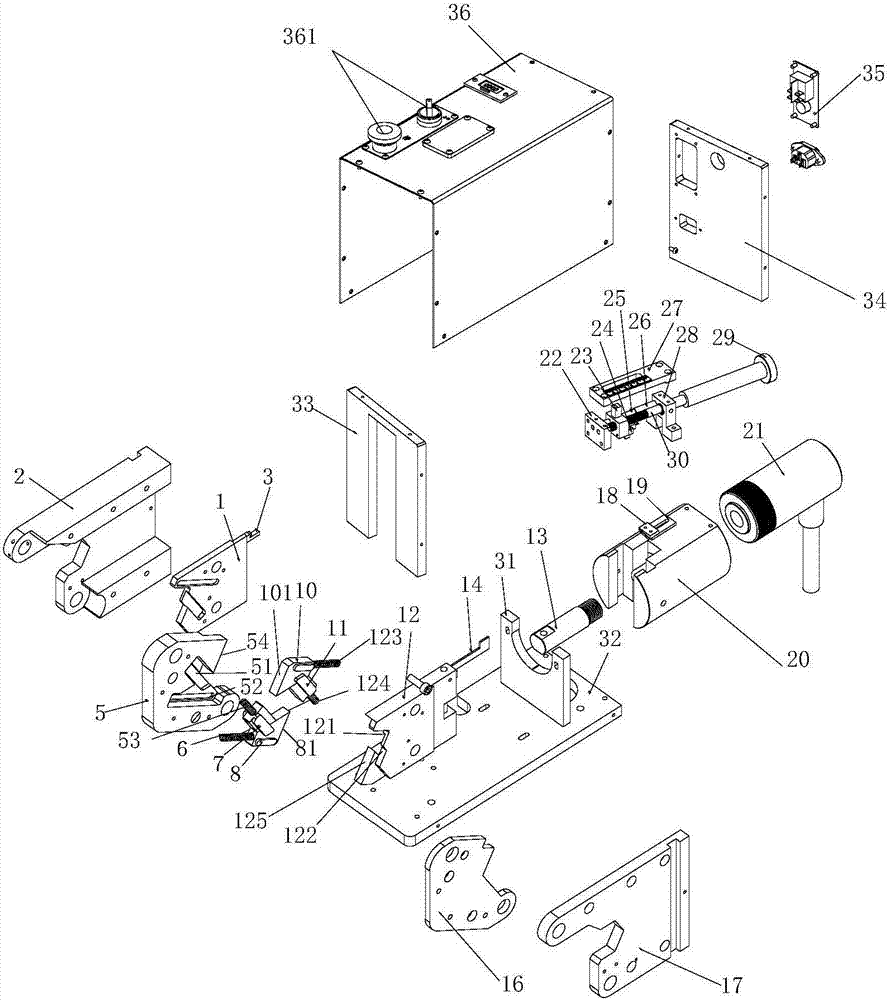

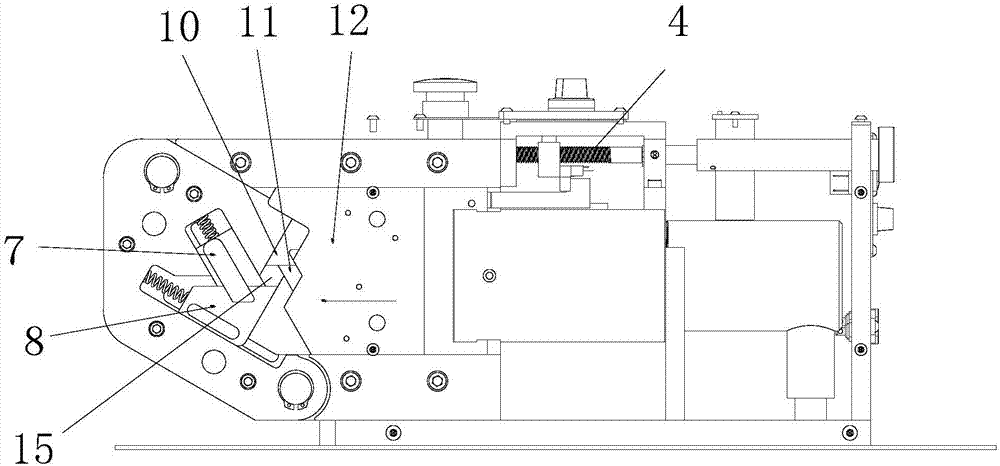

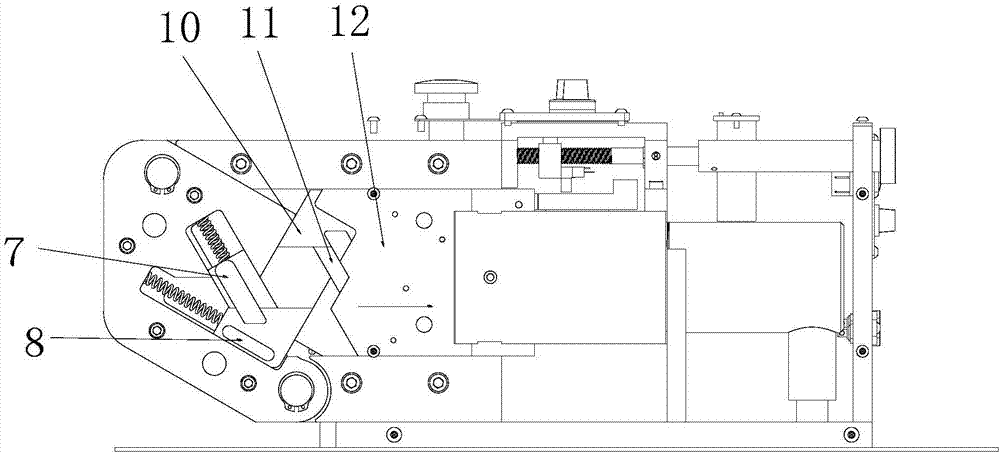

[0025] as attached Figure 1-3 As shown, the hexagonal terminal forming mold includes a mold base plate 32, a mold holder 2 is provided on the mold base plate 32, an inner mold holder 12 is movably installed in the mold holder 2, and an outer mold holder 5 is fixed on the mold holder 2. , the inner mold base 12 is provided with a first groove 121 and a second groove 122, and a first elastic member 123 and a second elastic member 124 are respectively arranged in the first groove 121 and the second groove 122, the first elastic Part 123 is connected with the first crimping slider 10, the second elastic member 124 is connected with the second crimping slider 11, the outer mold base 5 is provided with a third groove 51 and a fourth groove 52, the third groove 51 and The fourth groove 52 is provided with a third elastic piece 53 and a fourth elastic piece 6 respectively, the third elastic piece 53 is connected to the third crimping slider 7, the fourth elastic piece 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com