Counterweight support and motor applying the support

A technology of counterweight and counterweight block, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems that the rotor parts are not beautiful in appearance, increase the difficulty and cost, and are unfavorable for later replacement, and achieve simple structure, convenient and reliable use. , the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

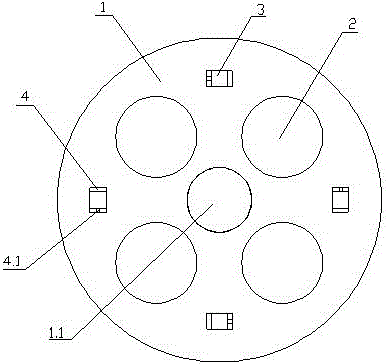

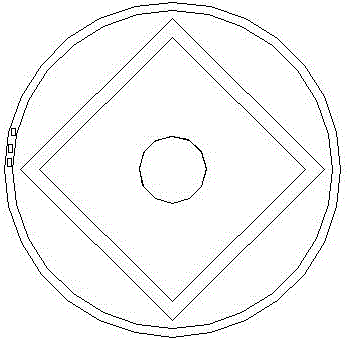

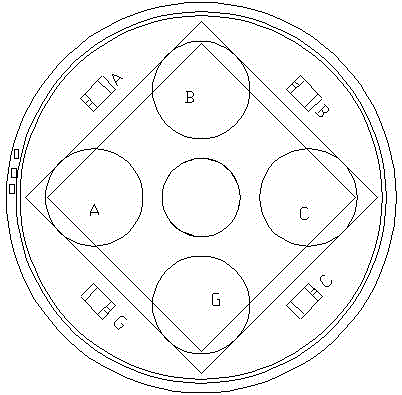

[0019] see Figure 1~3 , a kind of counterweight support that the present invention relates to, and described counterweight support comprises circular base 1, and the circular surface of described circular base 1 is uniformly provided with a plurality of counterweight mounting grooves 3, and described counterweight A counterweight is inserted in the installation groove 3, and ear plates 4 are vertically installed on both sides of the counterweight installation groove 3, and a positioning bolt hole 4.1 is arranged on one ear plate 4, which is screwed into the positioning bolt hole 4.1 The bolts of the counterweight are pressed against the other ear plate 4, so as to play a fastening role;

[0020] The above-mentioned counterweights are provided with a plurality of standard weights such as 1g, 2g, 5g, 10g, etc.;

[0021] A plurality of through holes 2 are evenly arranged on the circular surface of the circular base 1, which not only plays a role in reducing weight, but also doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com