High-performance field modulation magnetic gear

A magnetic gear, high-performance technology, applied in the field of gear transmission, can solve the problems of poor dynamic follow performance, large torque ripple, poor transmission stability, etc., to improve torque transmission capacity, reduce processing costs, and improve transmission stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

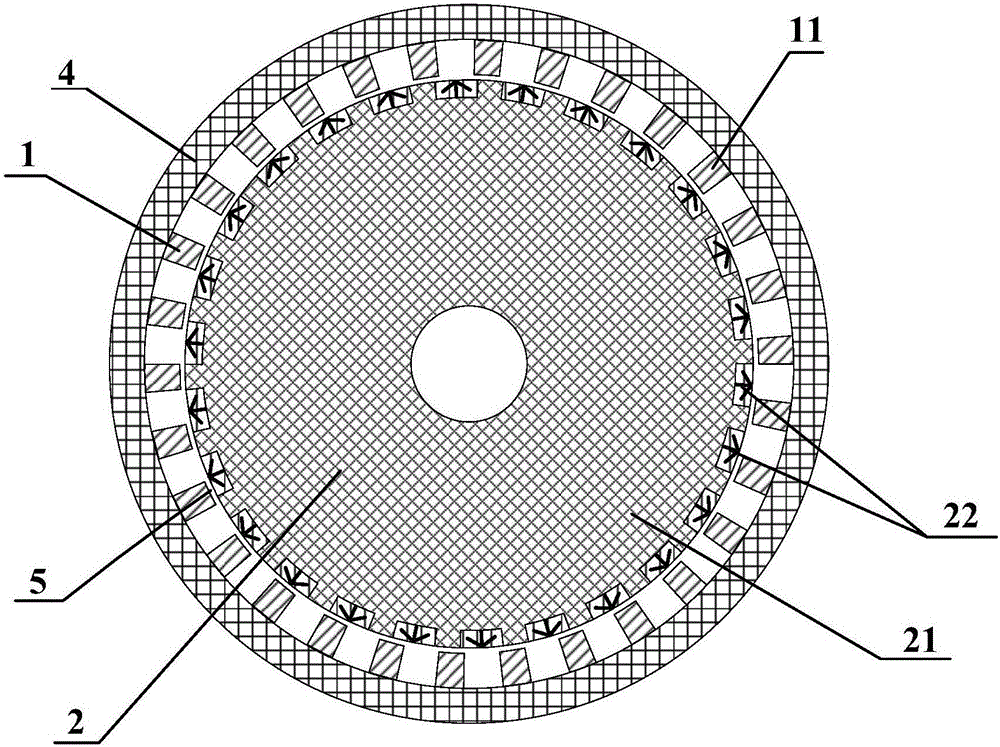

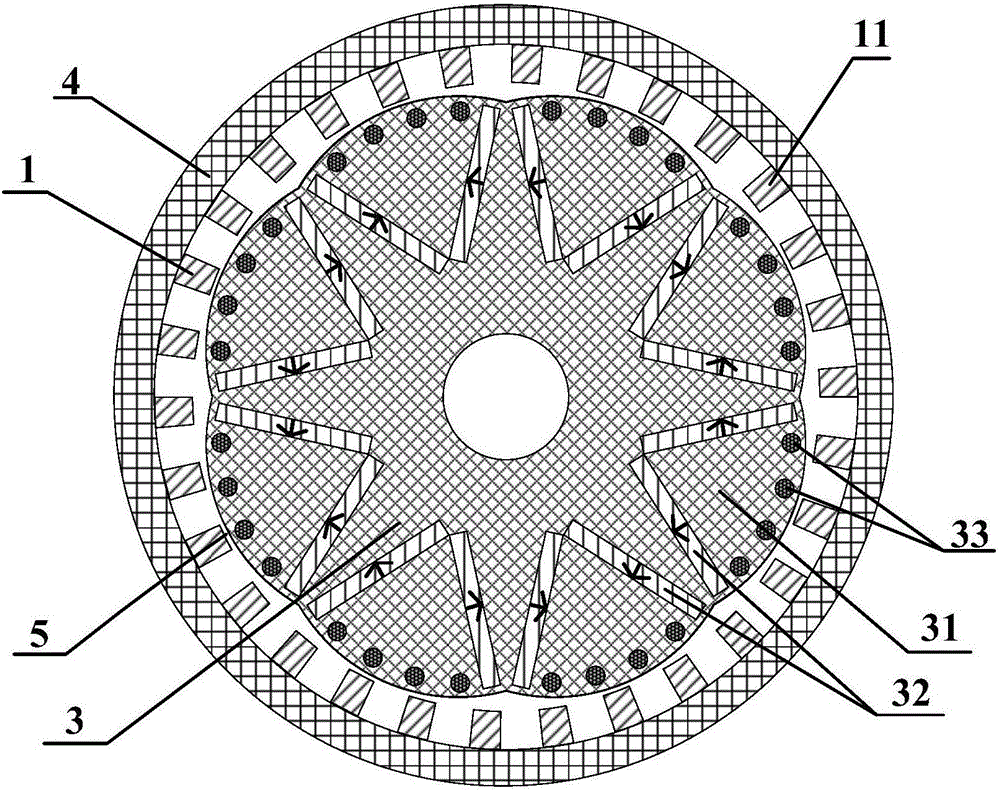

[0047] A high-performance field modulation magnetic gear, comprising a magnetic modulation ring 1, a low-speed rotor 2, a high-speed rotor 3 and a housing 4; The end surfaces on both sides of the ring 1 are respectively aligned with the outer end surfaces of the low-speed rotor 2 and the high-speed rotor 3 .

Embodiment 2

[0049] A high-performance field modulation magnetic gear as described in Embodiment 1, the difference is that the low-speed rotor 2 and the high-speed rotor 3 are arranged coaxially in the axial direction, with an axial gap between them; the magnetic modulation ring 1 A radial air gap 5 is provided between the outer surfaces of the low-speed rotor 2 and the high-speed rotor 3 .

Embodiment 3

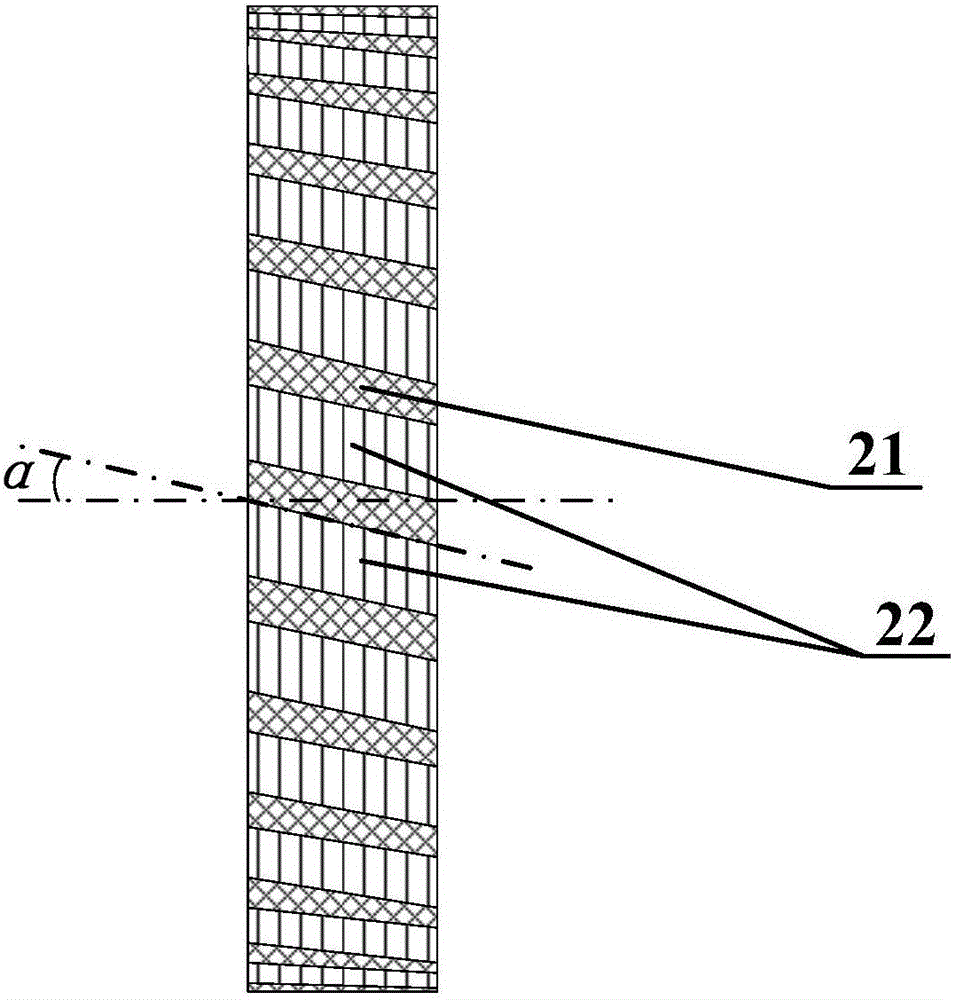

[0051] A high-performance field modulation magnetic gear as described in Embodiments 1 and 2, the difference is that the magnetic modulation ring 1 includes a plurality of parallel magnetic strips 11 arranged at equal intervals along the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com