Real-time monitoring device for the stiffness of earth-rock and asphalt concrete dam materials during the rolling process

A real-time monitoring technology for asphalt concrete, applied in the direction of measuring devices, radio wave measuring systems, instruments, etc., can solve the problems that the integrated control mode cannot be realized, the remote control of all parties participating in the project cannot be controlled, and the problems cannot be directly applied, so as to achieve improvement Convenience, ensuring construction quality, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

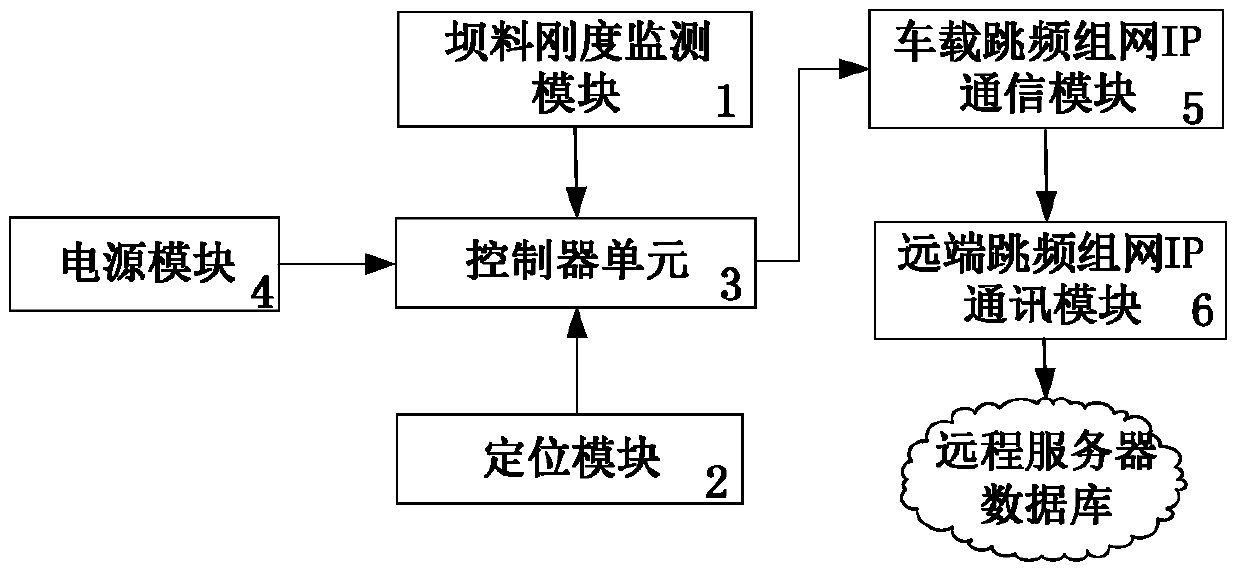

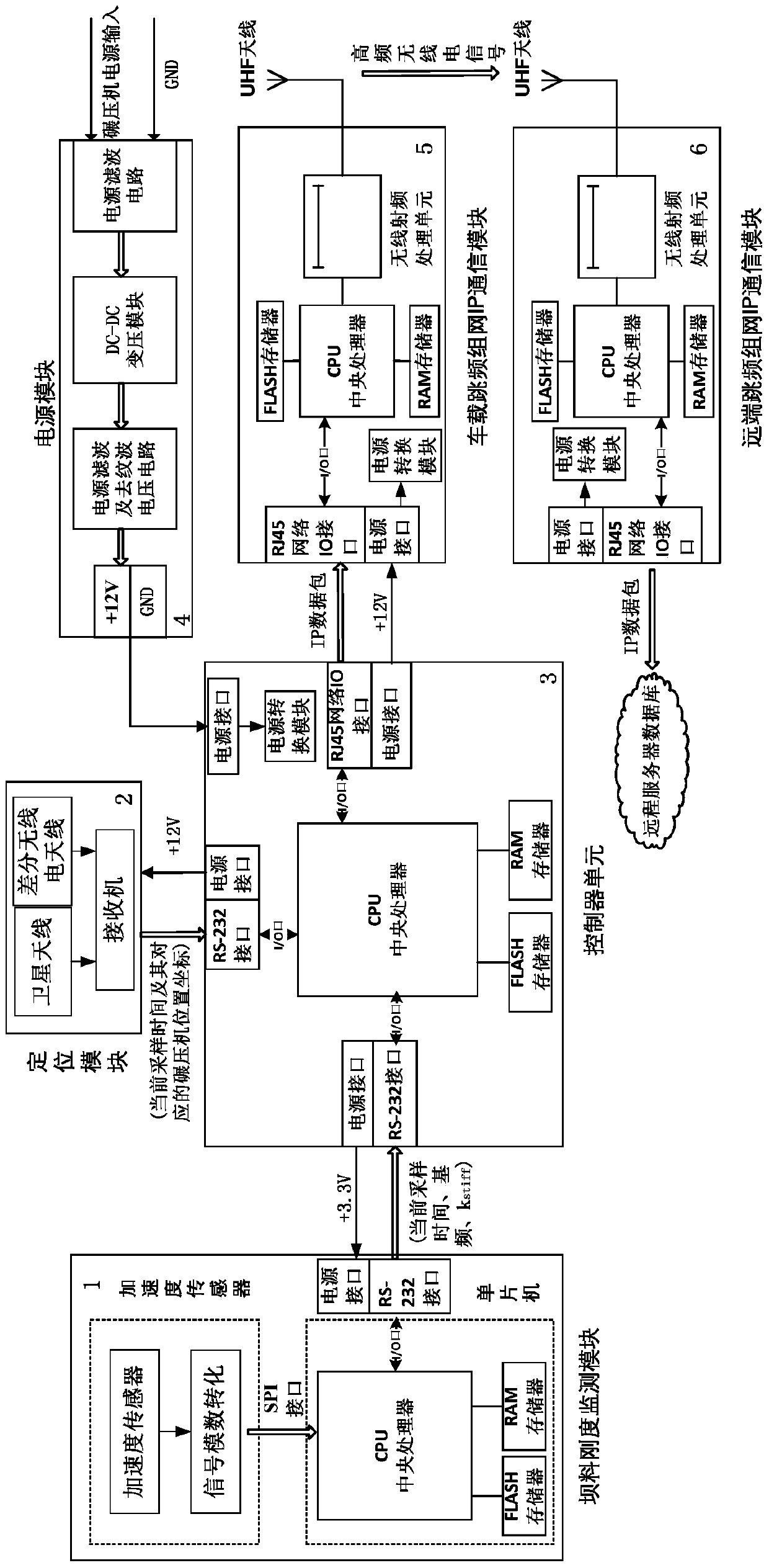

[0047] As a vehicle-mounted device, the device is installed on a roller compactor used for the construction of earth-rock dam materials and asphalt concrete dam materials. The device mainly includes six parts, such as figure 1 As shown, they are dam material stiffness monitoring module, positioning module, controller unit, power supply module, vehicle-mounted frequency hopping network IP communication module and remote frequency hopping network IP communication module.

[0048] The dam material stiffness monitoring module includes an acceleration sensor and a single-chip microcomputer, which is packaged and installed on the central axis of the vibrating wheel of the roller compactor and does not roll with the vibrating wheel. The acceleration sensor collects the acceleration analog signal of the vibrating wheel in real time, converts the signal into a time-domain digital signal through analog-to-digital conversion, and transmits the time-domain digital signal to the single-chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com