High-heat-dissipation-performance copper bar fixing structure

A fixed structure, high heat dissipation technology, applied to the circuit layout on the support structure, the circuit layout on the insulating board, etc., can solve the problems affecting the connection reliability of the copper bar, the horizontal displacement of the copper bar, and the fixation, so as to achieve the stability of the copper bar Strong performance and connection reliability, enhanced heat dissipation performance, and convenient current transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

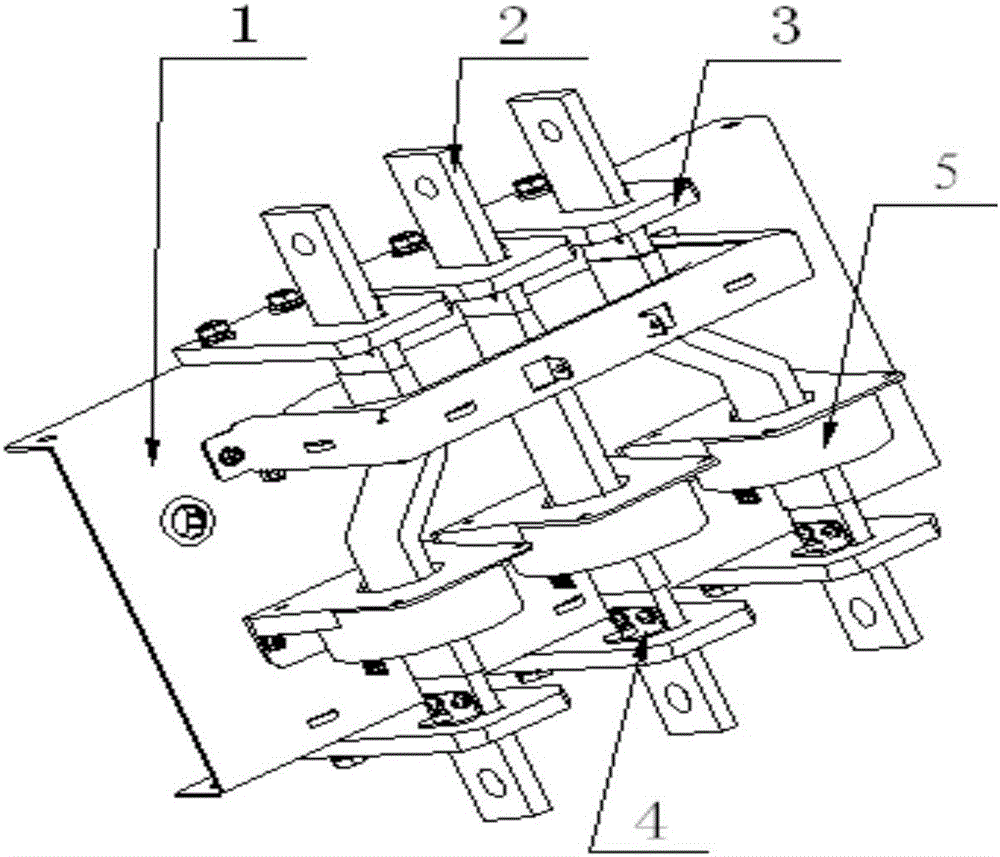

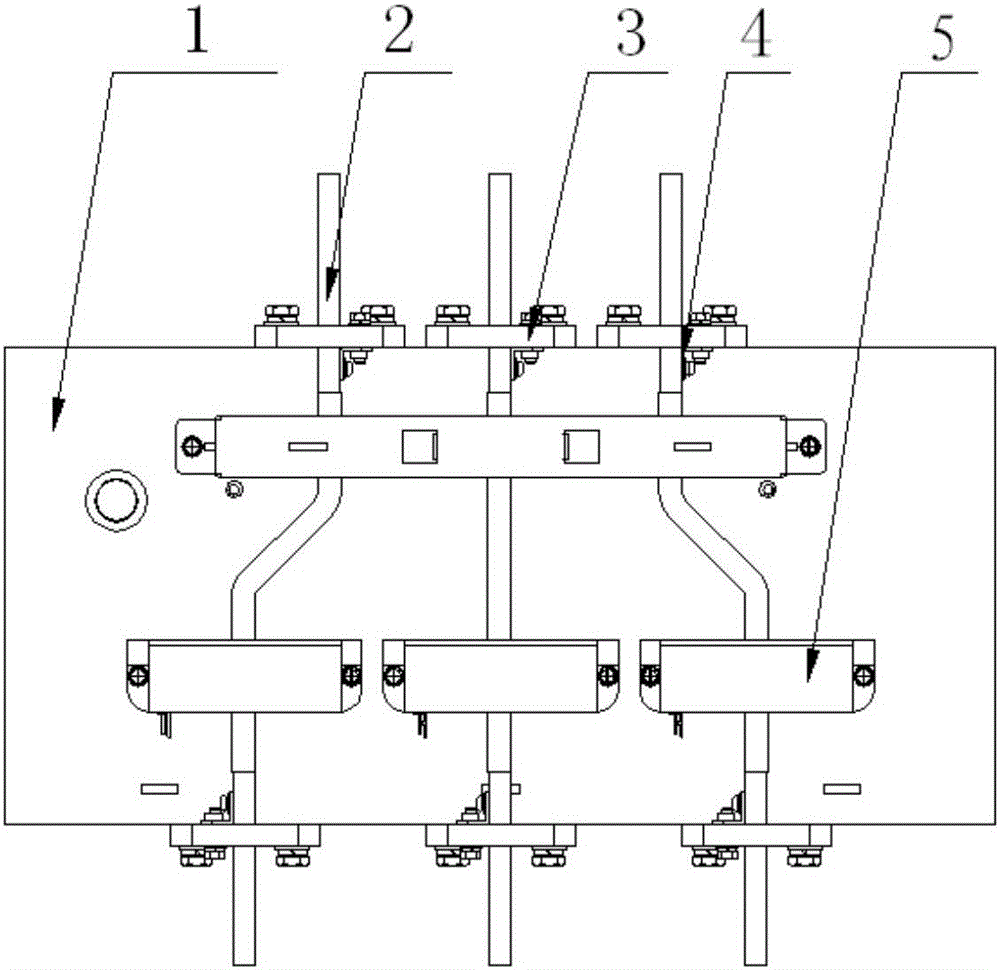

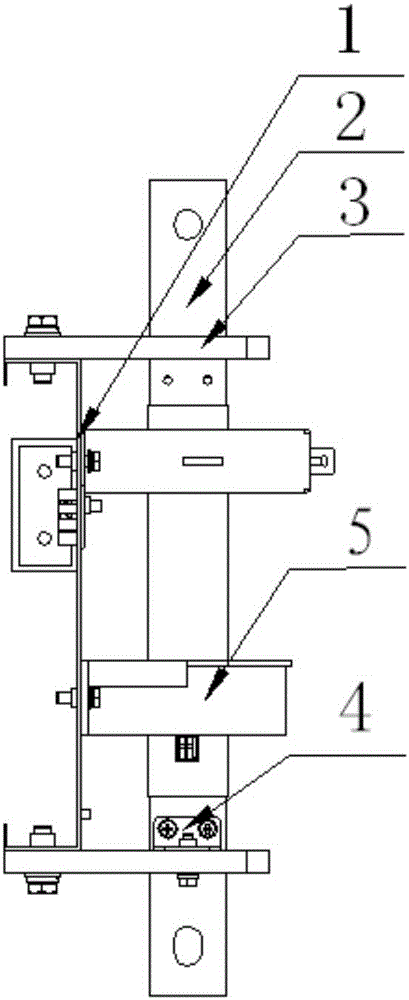

[0027] A copper bar fixing structure with high heat dissipation performance, including an installation base 1, a copper bar 2 and an insulating frame plate 3, the insulating frame plates are installed on the front and rear sides of the installation base correspondingly, and the copper bars are installed horizontally on the insulating frame plate. The innovation of the invention lies in: the L-shaped connecting piece 4 is used for fixed installation between the insulating frame plate and the copper bar on the front and rear sides of the installation base, so as to prevent the horizontal displacement of the copper bar due to the vibration of the equipment operation, Improve copper bar stability and connection reliability.

[0028] Three copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com