Leather clothing sewing process

A technology of leather clothing and craftsmanship, applied in clothing, textiles, papermaking, milling, etc., can solve the problems of slowing down the speed of embroidery, dropping the thread at the connection of strip leather, spending a lot of time and labor, etc., to ensure firmness and safety. Stability, reduced embroidery error rate, convenient effect of removing the paper shell layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

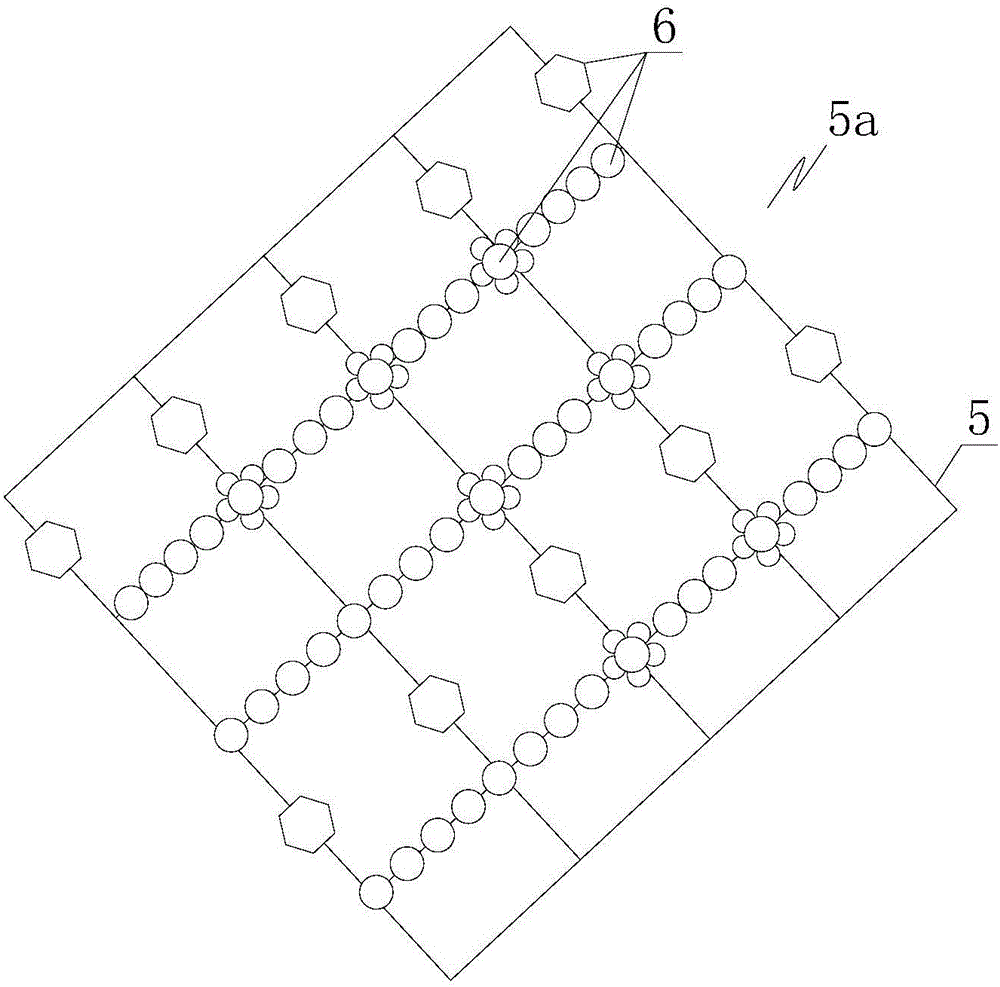

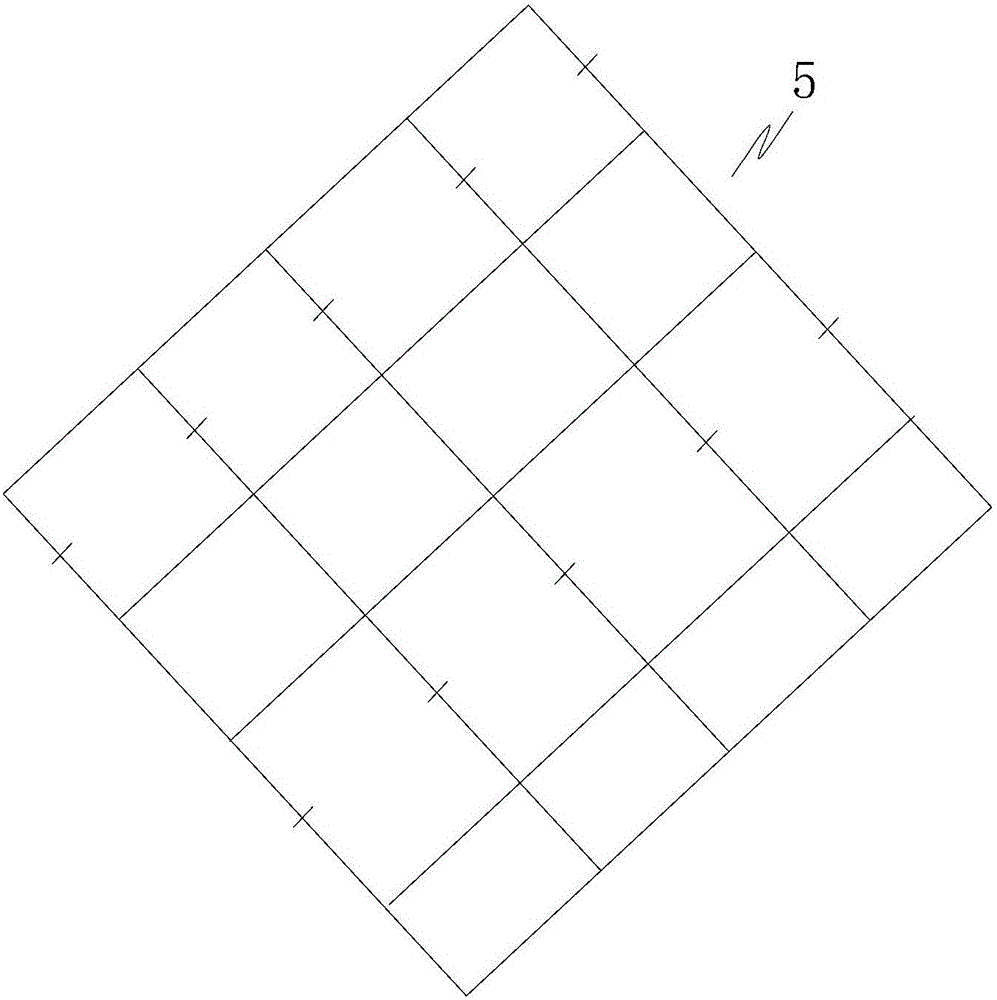

[0047] Such as Figure 1-13 Shown, a kind of leather clothing sewing process comprises the following steps:

[0048] (1) Style design, design the garment style and embroidery pattern by hand or computer, and determine the embroidery position on the designed garment style, such as the upper part of the sleeve 14 or the back of the body 15 .

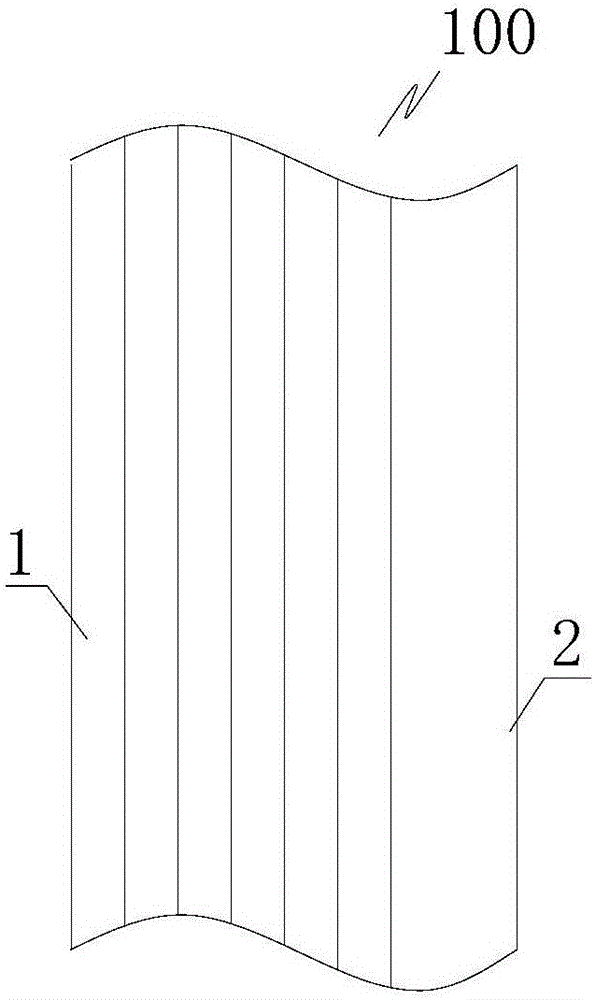

[0049] (2) Structural design, design the specific size of the garment style, such as the length and width of the garment body 15, the length and diameter of the sleeve 14, etc., and calculate the number and size of the strips 1 that need to be divided into, that is, the garment body 15, The number of leather strips required for the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com