Selective laser melting single-knife two-way powder laying device and selective laser melting equipment

A technology of laser selective melting and powder spreading device, which is applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc. It can solve the problems of many auxiliary equipment, powder pollution, and complex structure of powder spreading device, so as to reduce equipment cost, Effect of cost saving and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

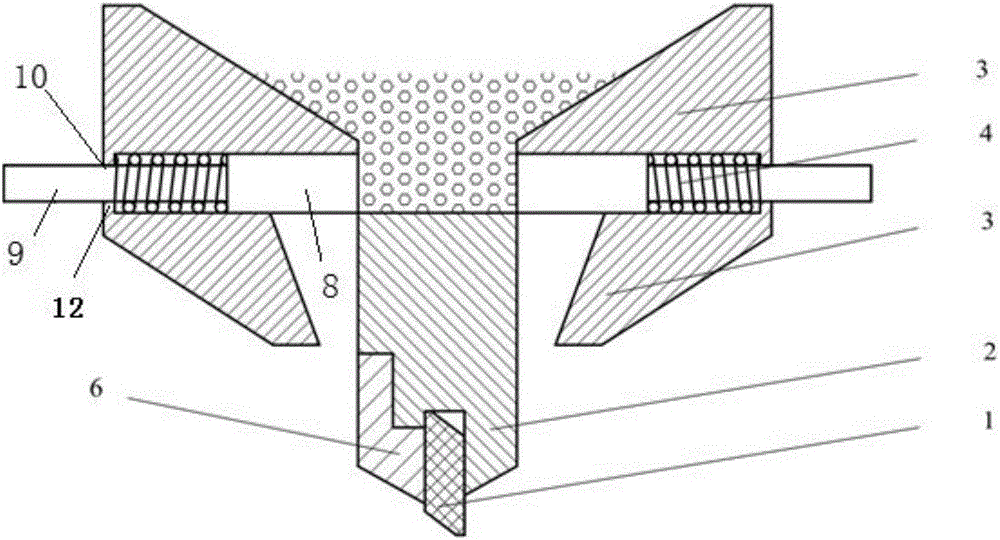

[0023] The single-knife two-way powder spreading device for selective laser melting of the present invention is as follows: figure 1 As shown, it includes a scraper 1 , a scraper holder and a powder feeding unit 5 ; the scraper holder includes a scraper holder main body 3 and a scraper installation frame 2 . Wherein, the scraper holder main body 3 is a hollow structure with upper and lower openings, and its upper opening is funnel-shaped, which facilitates the smooth falling of powder; the scraper holder main body 3 is respectively provided with two through holes 10 on both sides of the powder spreading direction.

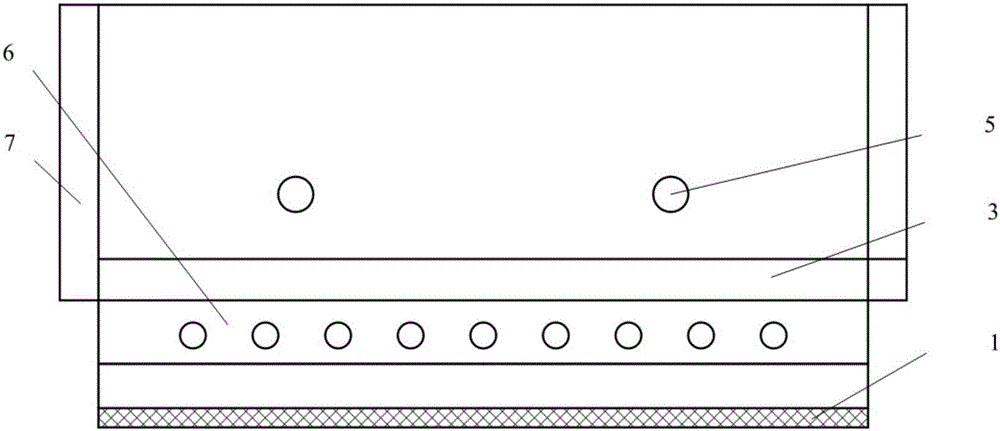

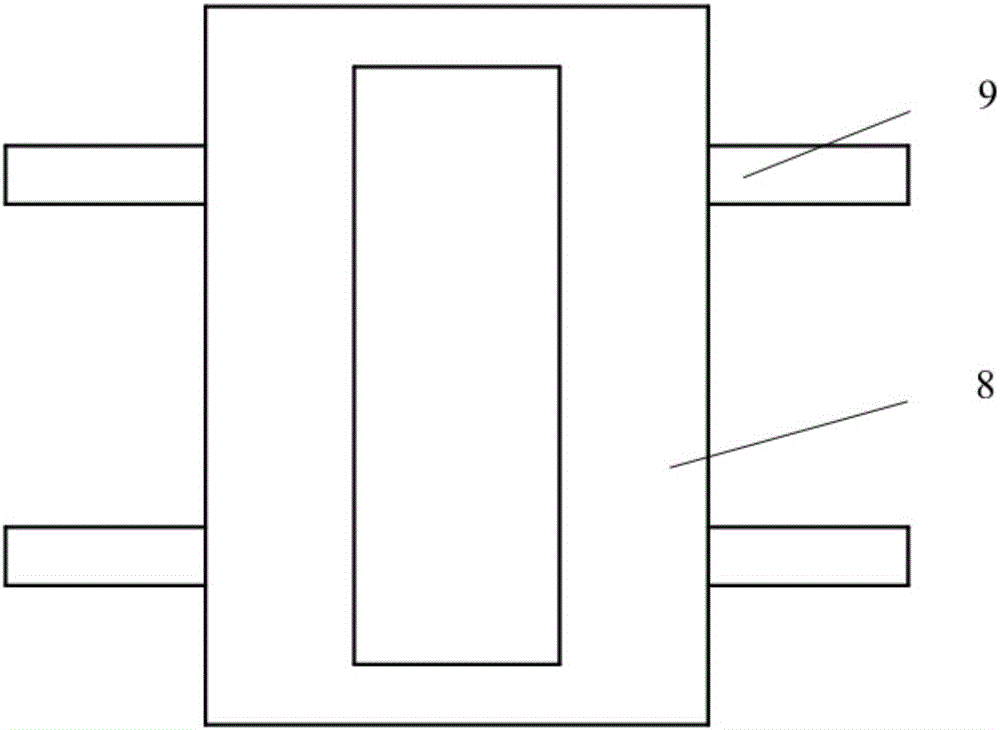

[0024] Powder feeding unit 5 such as figure 2 As shown, it includes a powder feeding plate 8 with a central opening, and two powder feeding rods 9 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com