A Simple Improvement Device for Jet Mill Filter

A filter and jet mill technology, applied in the direction of cyclone devices, etc., can solve the problems of reducing the effective running time of the equipment and product stability, the filtration effect of the nano-scale filter being deteriorated, and the continuous production of the jet mill equipment. Continuous accumulation, good separation, increased weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

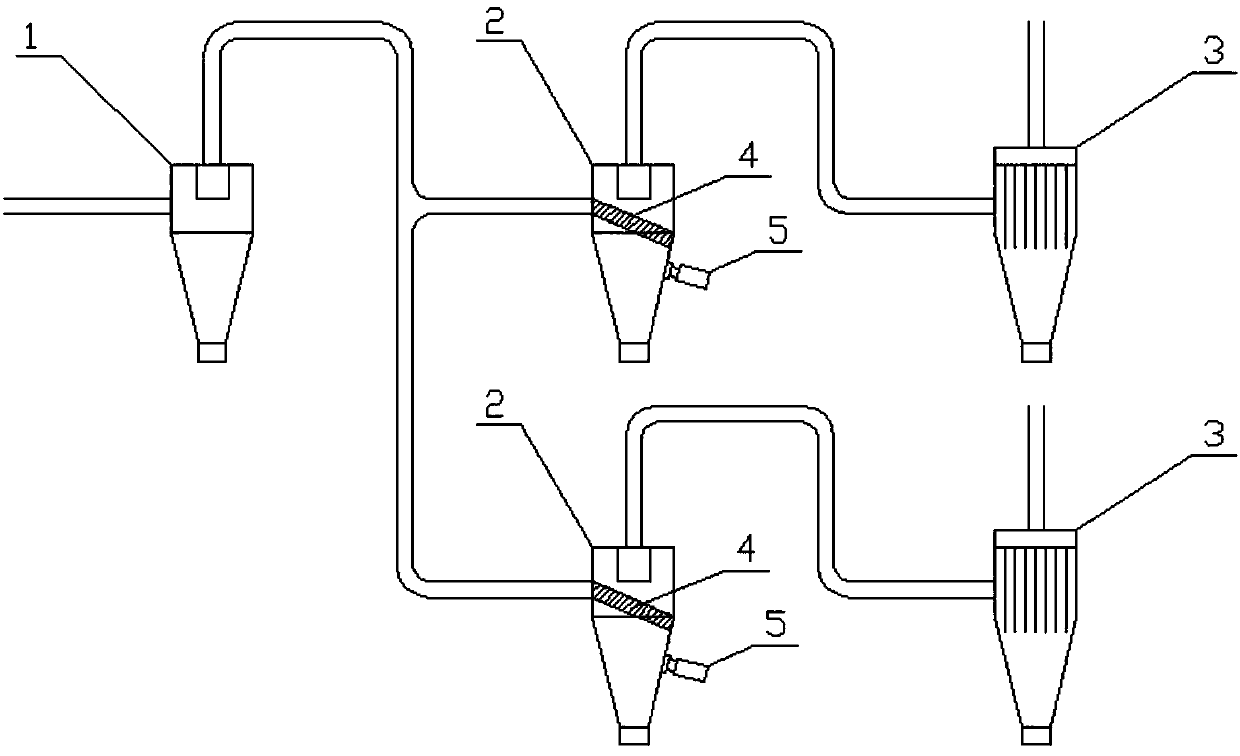

[0025] refer to Figure 1-5 As shown, a simple improvement device of a jet mill filter of the present invention includes a primary cyclone separator 1 and a nanoscale filter 3, wherein the device also includes: 1 to 2 secondary cyclone separators 2, the two The primary cyclone separator 2 is connected in series between the primary cyclone separator 1 and the nanoscale filter 3 .

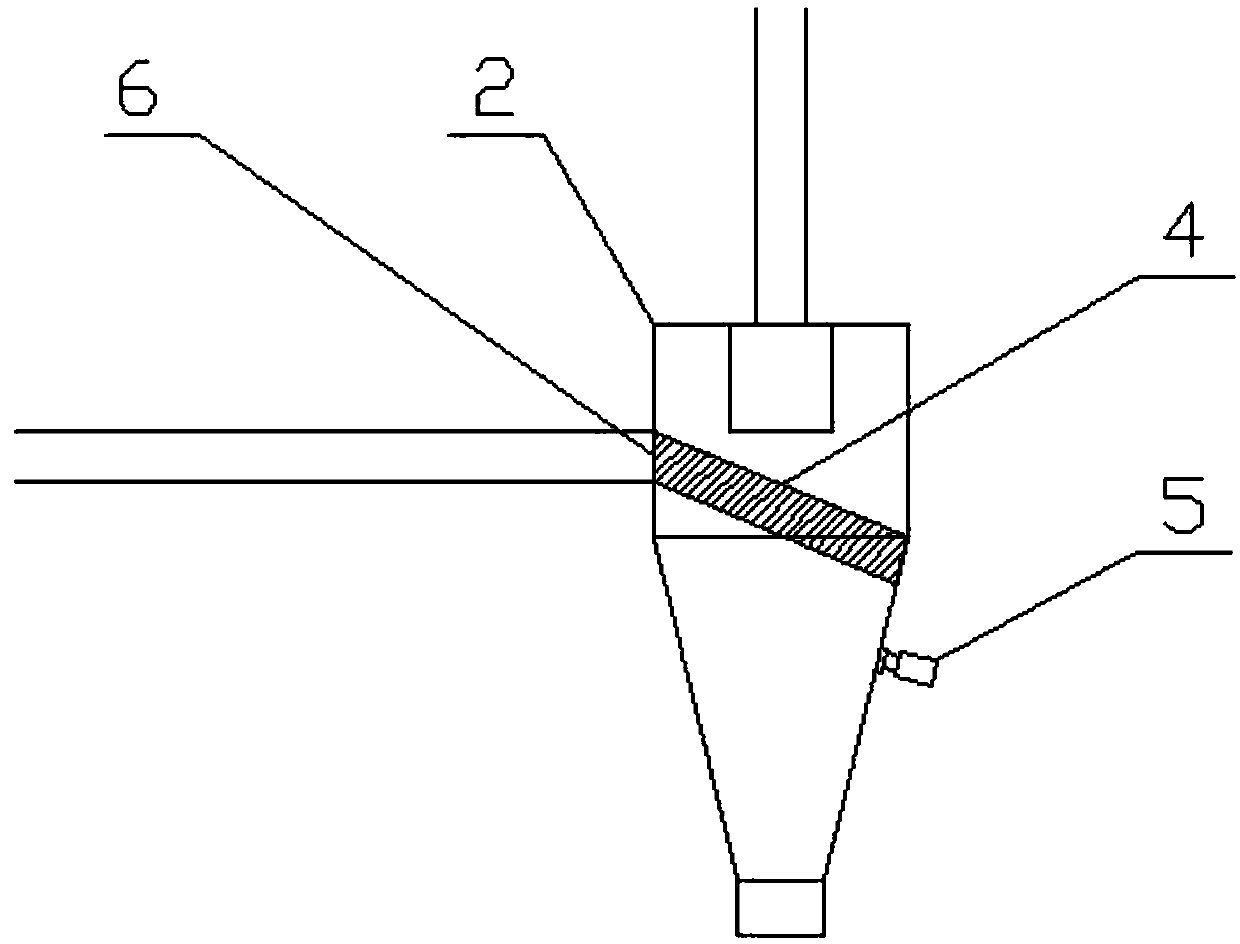

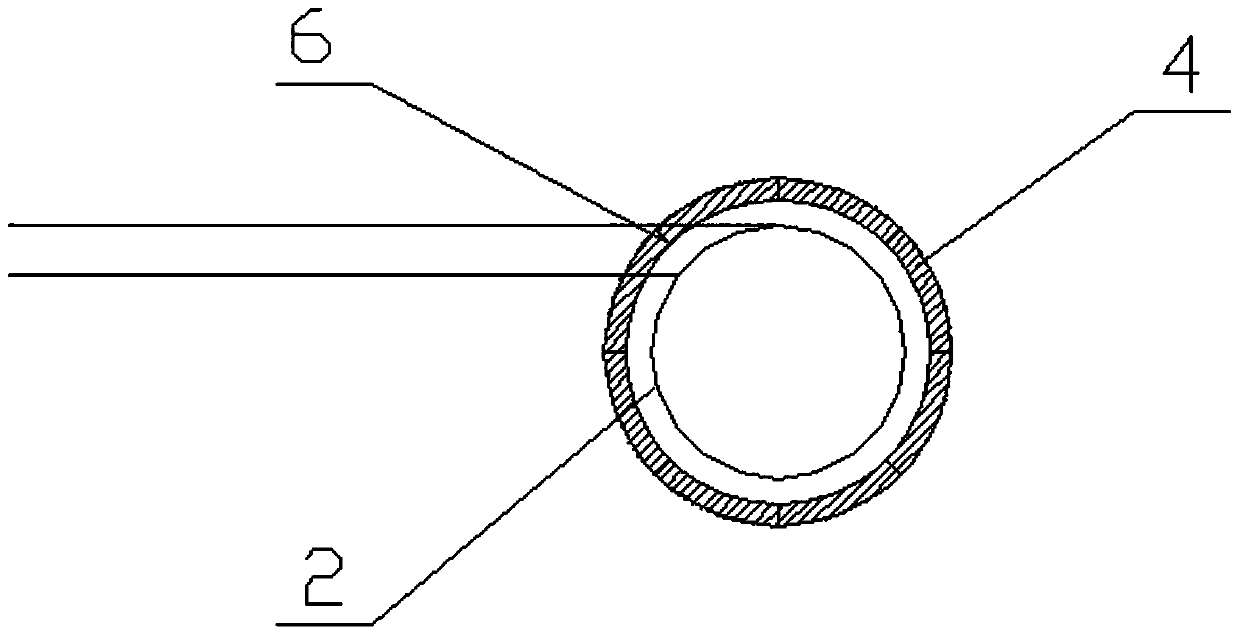

[0026] Such as figure 2 and image 3 As shown, the above-mentioned simple improvement device for jet mill filter also includes a magnet 4 which is arranged outside the secondary cyclone separator 2 . Further, the simple improvement device of the jet mill filter also includes a vibrator 5, which is fixed on the outer wall of the secondary cyclone separator 2, and when the equipment stops or works for a long time, more powder adheres to the magnet In the surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com