Strong mechanical wire scissors

A powerful mechanical and force arm technology, which is applied to cable installation devices, metal processing, electrical components, etc., can solve problems such as low work efficiency, laborious cutting of large-diameter wires, and increased risk rate, so as to improve mechanical efficiency and facilitate The effect of carrying and prolonging the service life for climbing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

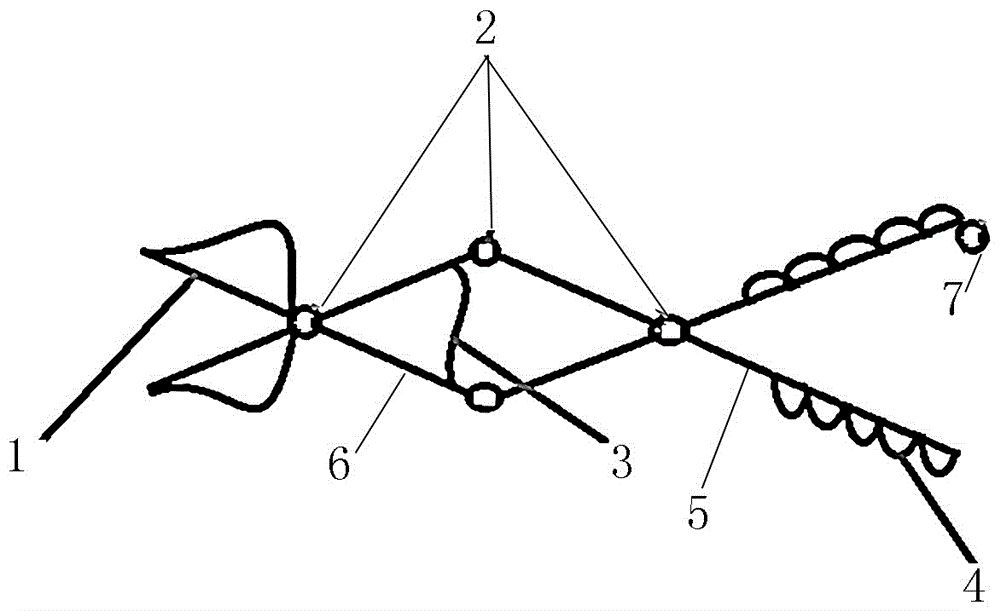

[0014] Such as figure 1 As shown, the main body includes a dual force arm 6, a pure steel notch 1 and a handle 5. The two sets of force arms of the double force arm are connected in a rhombus shape, and one group of force arms of the double force arm are arranged crosswise with the pure steel notch. The other set of force arms of the arm is crossed with the handle. The connection points between the double force arms and the intersection points between the double force arms and the notch and the handle are all connected by bearings 2, and a spring 3 is arranged between the connection points of the double force arms. ; The handle is set with a grooved insulating sheath 4, and the handle is provided with a hanging ring 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com