Unloading device used on forklift

A technology of unloading device and forklift, which is applied in the direction of lifting device, etc. It can solve problems such as rollover and poor anti-torsion ability, and achieve the effects of high holding strength, high anti-rollover ability, and large power output capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

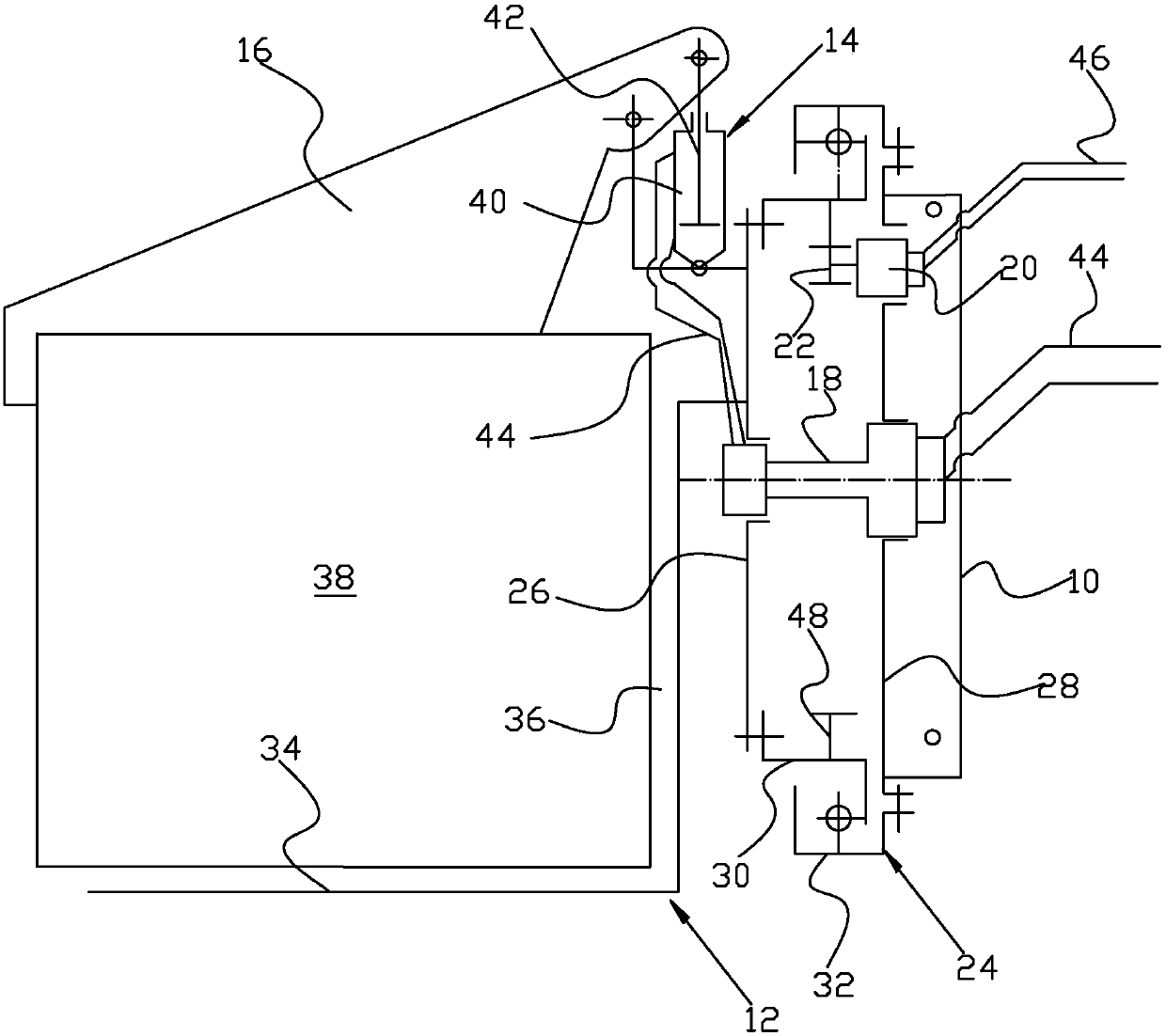

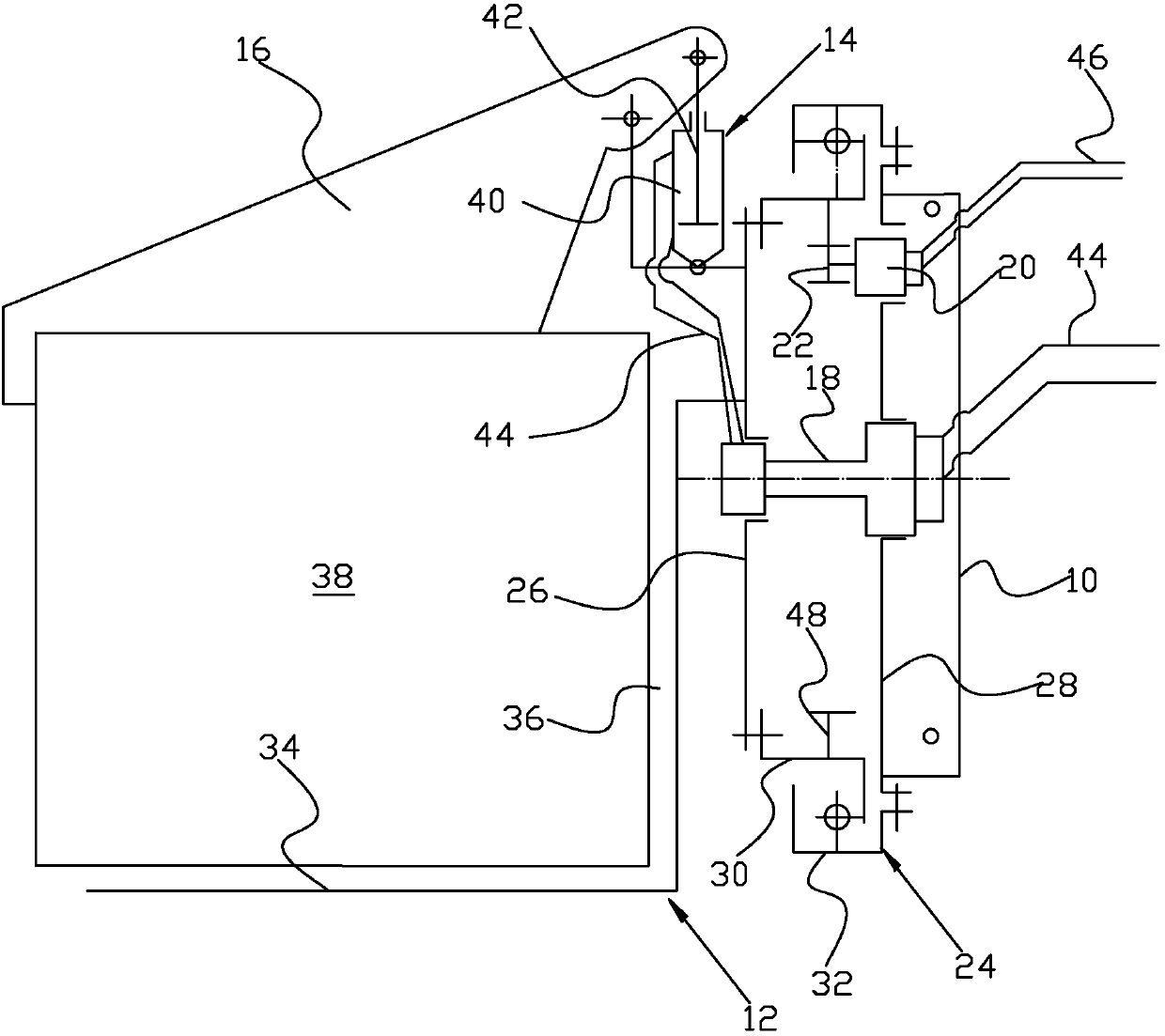

[0022] Please check figure 1 , an unloading device used on a forklift, including a lifting seat 10, a fork part 12, a holding drive mechanism 14, a holding mechanism 16, a center seat 18, a rotating drive mechanism 20, and a driving gear 22 , a slewing bearing 24, a front mounting plate 26 and a rear mounting plate 28, which are used to unload loose materials in the container 38, such as: ore, loose coal, grain, engineering soil, bulk cement , iron pellets or various types of urban and civil waste and other bulk materials.

[0023] The lifting base 10 can be lifted up and down, so that the lifting base 10 can be lifted by a fork-loading function. The center base 18 has a rotating structure and is fixed on the lift base 10 . The rear mounting plate 28 is fixedly sleeved outside the center base 18 and fixedly connected to the lift base 10 . The rotation driving mechanism 20 is fixedly connected to the non-eccentric position (not located in the center seat) of the rear mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com