A method for overall removal of box girder bottom formwork

A bottom formwork and box girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of construction unit schedule pressure, low efficiency of steel formwork, and high construction risk factor, saving materials and shortening operation cycle. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

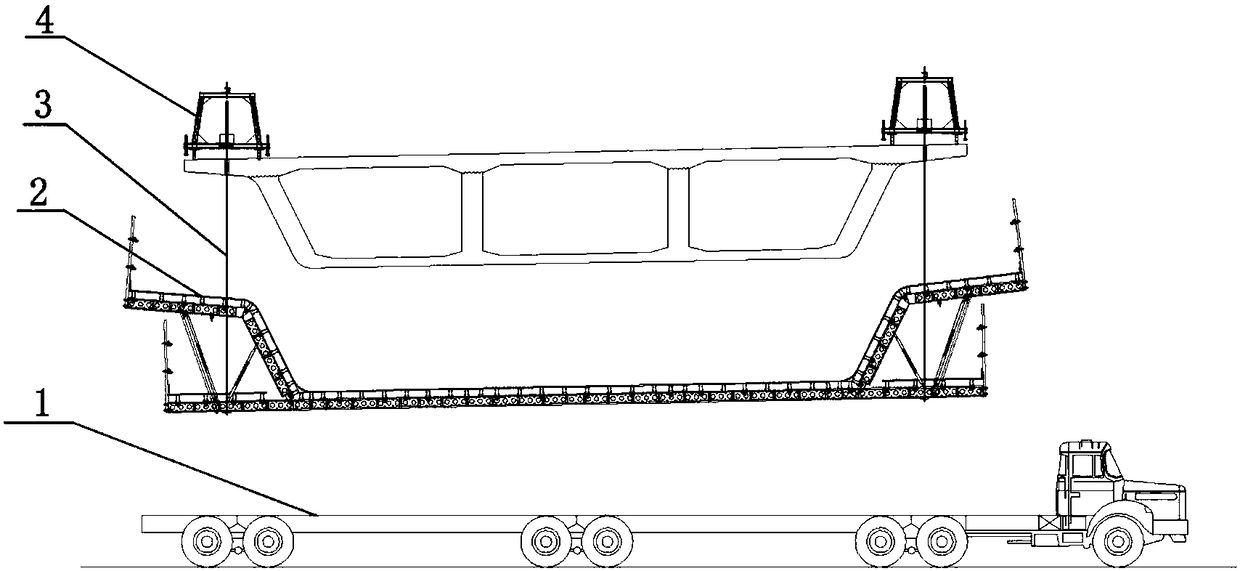

[0016] A method for dismantling a box girder bottom form as a whole, the steps of which are:

[0017] (1) Pre-buried formwork removal holes: 80mm formwork removal holes are pre-embedded before the roof is poured, so that the pre-embedded pipes used to set the formwork removal holes on the roof are at the same vertical position, and iron chains are inserted into the pre-embedded pipes;

[0018] (2) Penetrating bolt reinforcement: After the top slab is poured, the box girder bottom formwork and roof are reinforced with piercing bolts, and the contact position between the top plate and the piercing bolts is padded with a "concave" piercing gasket;

[0019] (3) The overall removal of the bottom formwork of the box girder: after the bolts are reinforced, the scaffolding at the bottom of the box girder is removed. After the scaffolding is removed, the electric hanger is moved to the top of the demoulding hole, and the piercing cap is used to connect the piercing Bolts, after the fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com