Component type insulation fireproof curtain wall structure

A technology for fire curtains and components, applied in building components, walls, building structures, etc., can solve the problems of many panel fixing points, shortened construction period, poor thermal and fire performance, etc., to achieve good safety performance, lateral strength guarantee, The effect of good fire insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

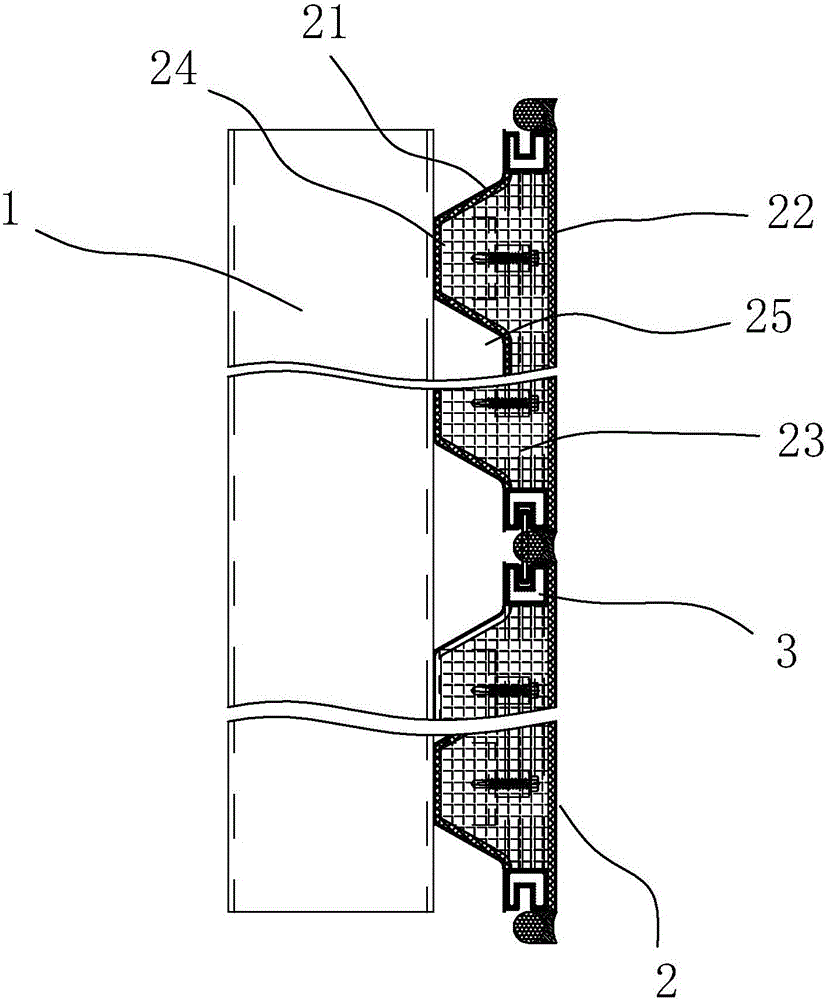

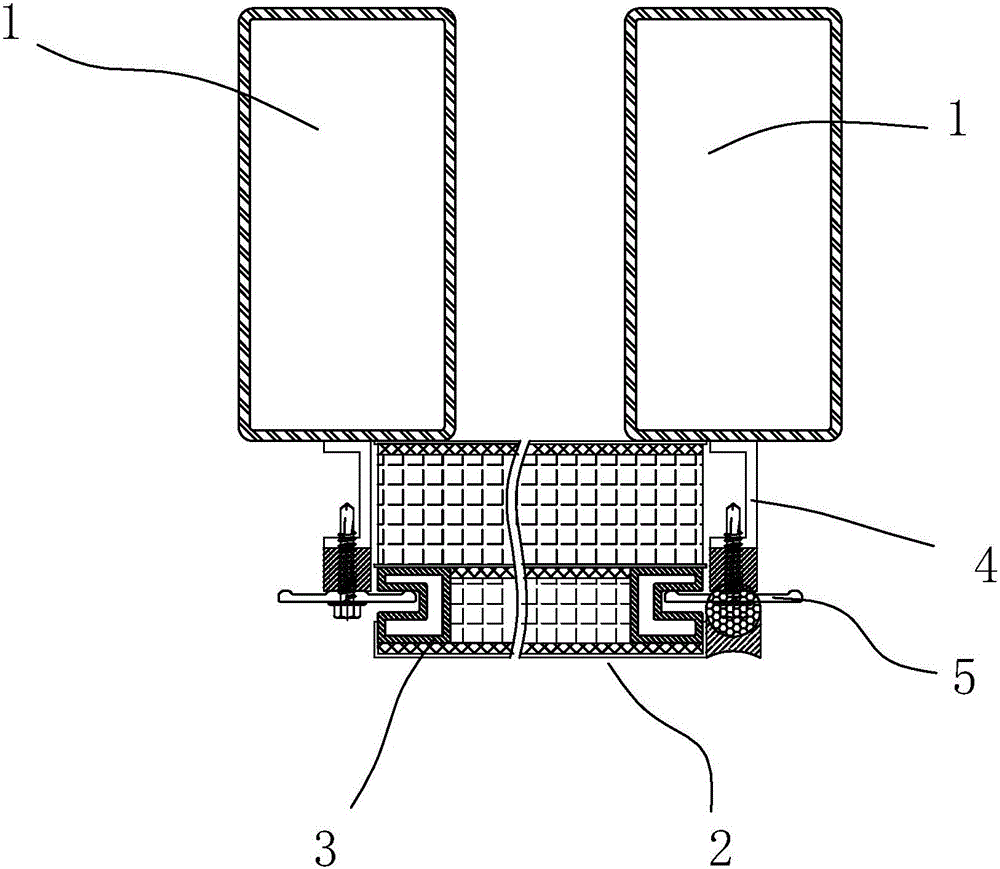

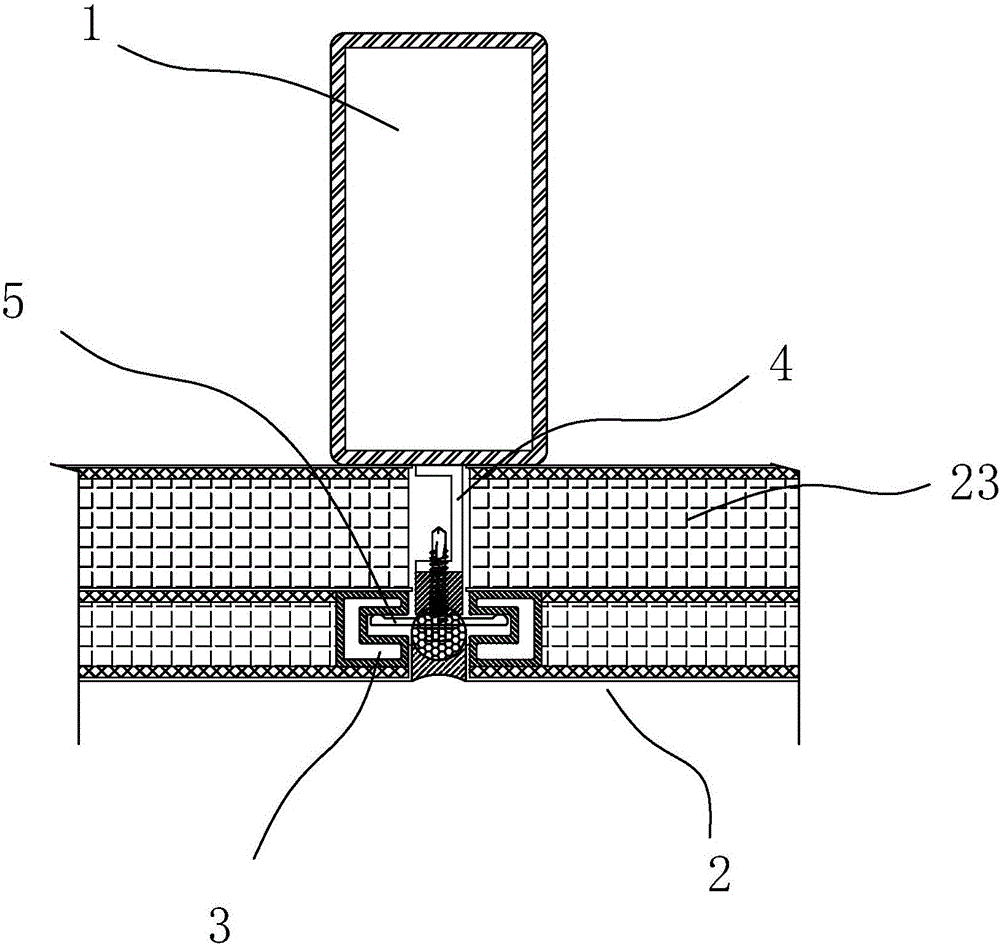

[0021] refer to Figure 1 ~ Figure 4 , the present invention is a component type thermal insulation and fireproof curtain wall structure, comprising several vertical keels 1 installed in parallel between the building structure layers and several curtain wall panels 2 installed between two adjacent vertical keels 1, each curtain wall panel 2 includes The profiled steel plate 21 and the decorative panel 22 as the decorative surface layer are filled with fireproof and heat-preserving rock wool 23 between the profiled steel plate 21 and the decorative panel 22, and there are also partitions connected between the profiled steel plate 21 and the decorative panel 22 on both sides. The hot and warm side 3 and the heat-insulating warm side 3 form a concave bridge installation groove, and each vertical keel 1 is installed with a channel steel connector 4 between the two curtain wall panels 2, and is also provided with a screw that is installed in the groove. The fixed bracket 5 on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com