An underground surrounding rock fault support device and support method

A supporting device and fault technology, which is applied in shaft equipment, shaft lining, underground chambers, etc., can solve the problems that cannot meet the stability requirements of surrounding rocks, and achieve the effect of improving self-supporting capacity and stability, and increasing filling radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

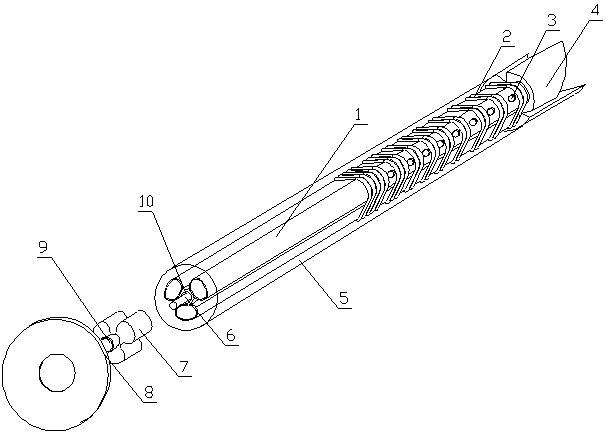

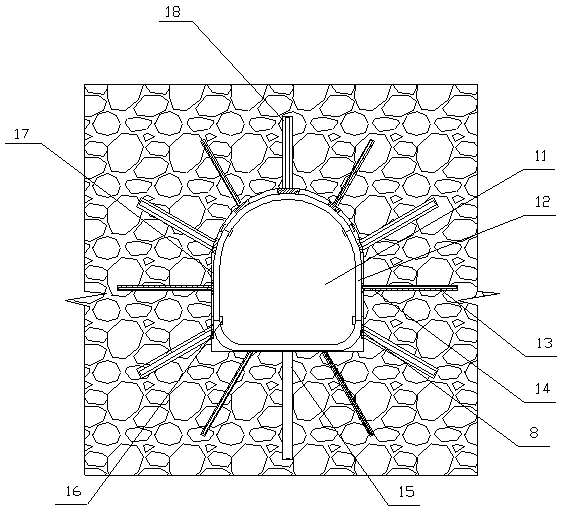

[0038] A kind of downhole surrounding rock fault support device and support method of the present invention are realized in this way, further elaborated below:

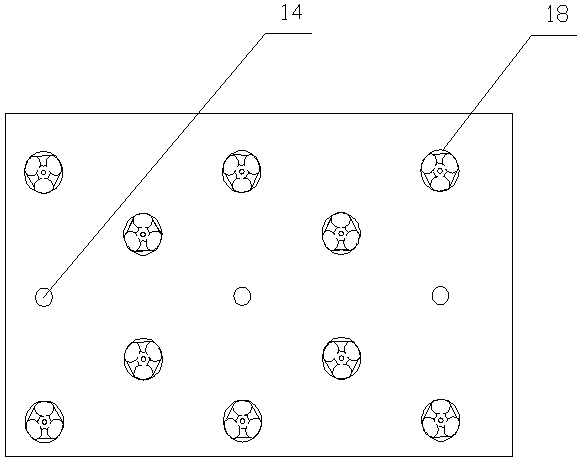

[0039] 1) Comprehensively use advanced geological exploration and other means to survey the surrounding rock faults, and then arrange advanced drilling, drill holes with a drilling rig on the side wall of the fault roadway, and drill a central hole at the height center position, with a diameter of φ20mm and a depth of 2800mm; the center holes are spaced in pairs 2000mm, the drilling direction of the central hole is perpendicular to the tangent direction of the circumscribed circle of the fault roadway;

[0040] 2) With the center hole as the center, drill support holes. The six support holes are distributed in a regular hexagon around the center hole. The distance between the support holes is 1000mm. The direction of the support hole mentioned above is perpendicular to the tangent direction of the circumscribed circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com