Realizing method of axial slot casing with low mixing losses

A realization method and axial technology, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as peak efficiency loss, reduce friction loss, enhance suction effect, and reduce mixing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Some design parameters of the compressor rotor in this embodiment are shown in Table 1.

[0026] Table 1 Some design parameters of the rotor

[0027]

[0028]

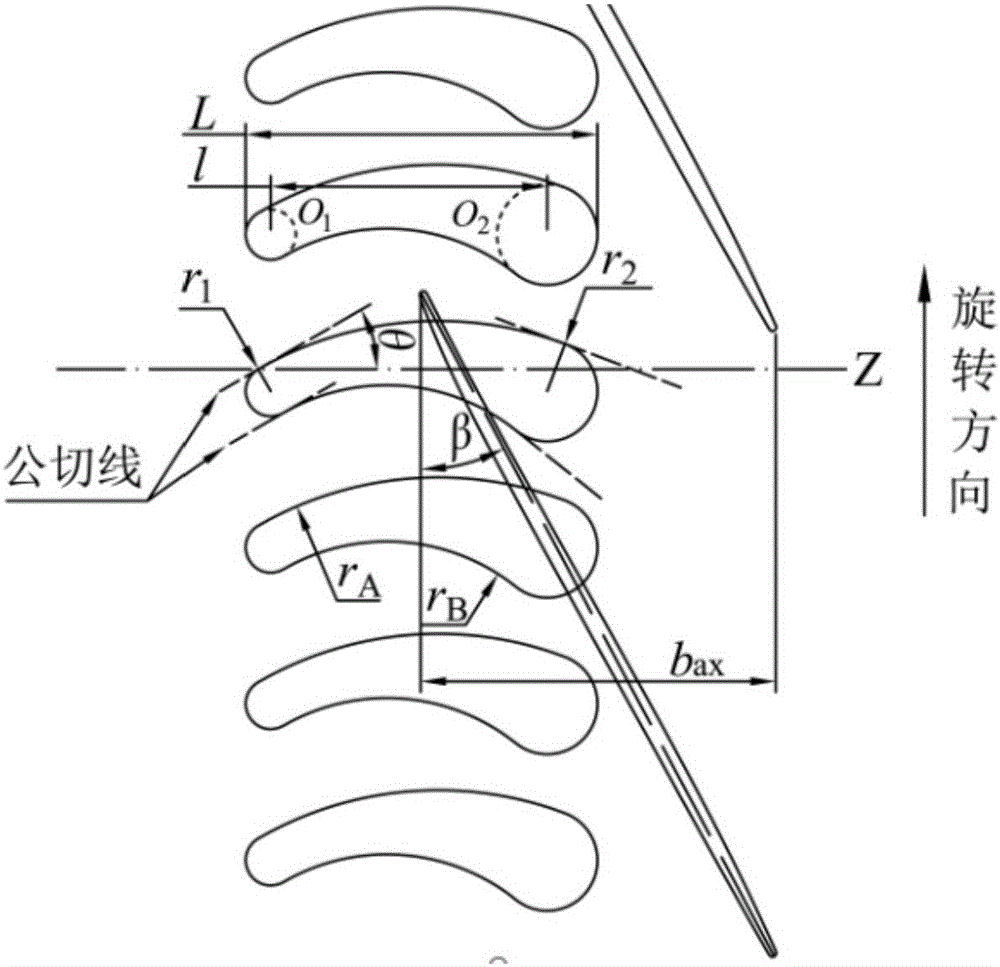

[0029] Firstly, within the critical flow area of the blade tip, determine the processing range and axial length of the treatment slot in the axial direction. After determining the radius of the front end circle and the radius of the rear end circle of the treatment slot, construct the inner and outer common tangent of the two circles. Arc, the obtained four arcs form a complete axial processing seam. The steps to achieve an axial seam casing with low blending losses include:

[0030] 1) The rotor blade is modeled, and the internal flow field is numerically simulated to obtain the tip flow field structure and flow characteristics near the stall point, and determine the critical flow area of the tip.

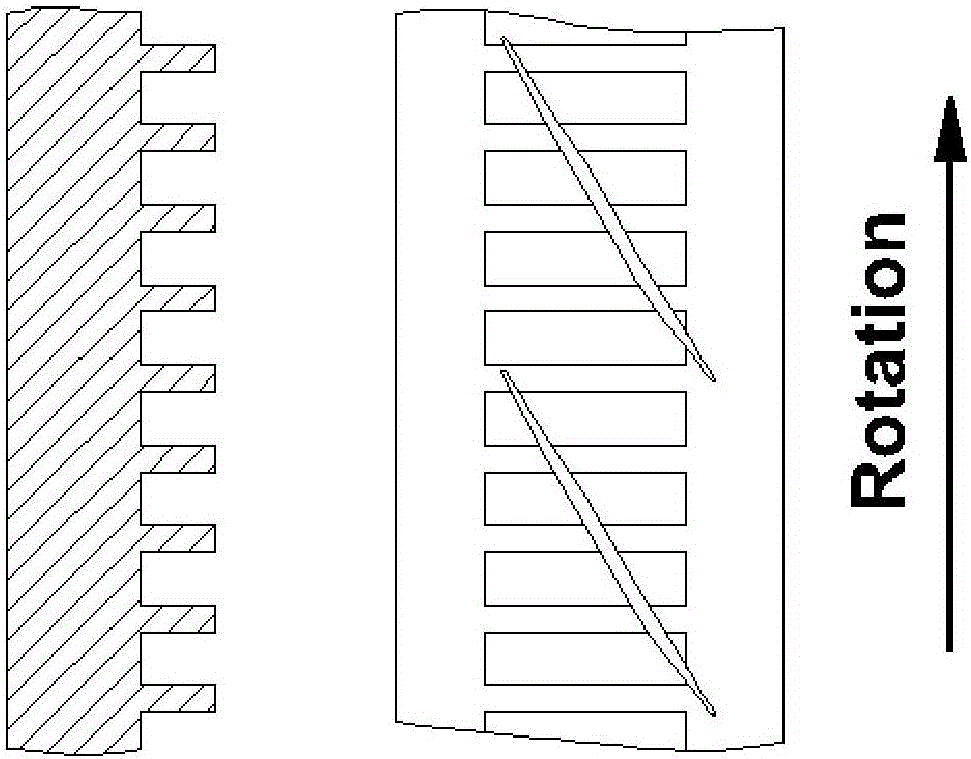

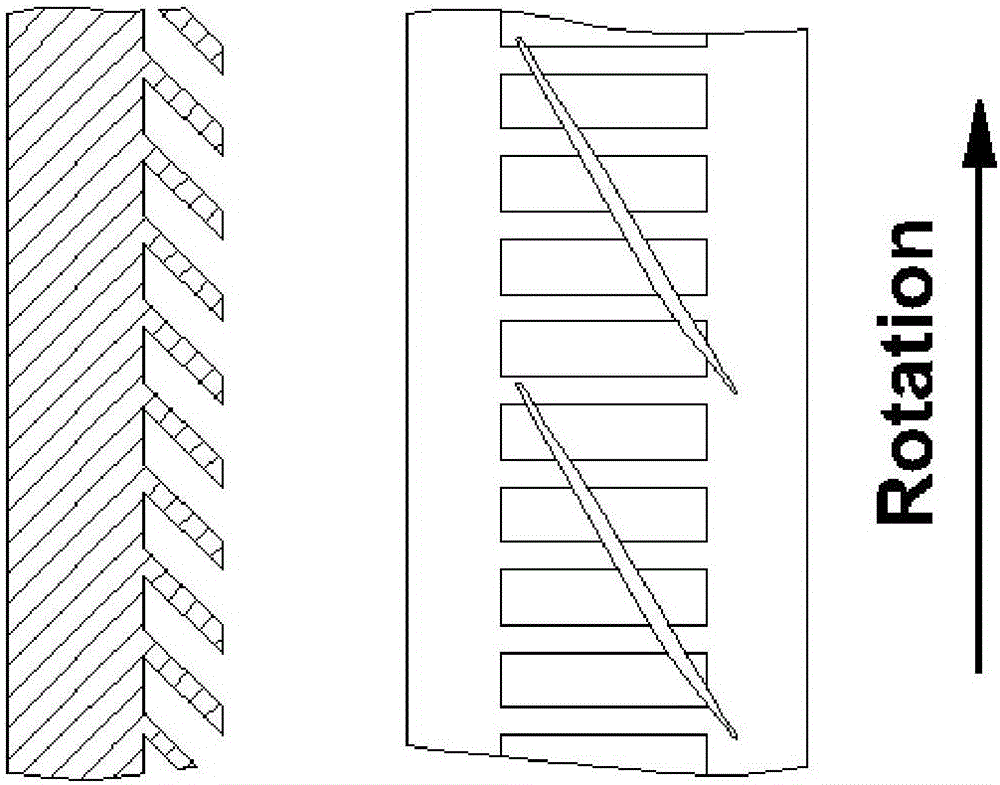

[0031] 2) if image 3 As shown, determine the range of the treatment slot in the axial direction, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com