Disc-shaped star wheel of single-screw compressor and its forming process

A single-screw compressor and molding process technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as excessive clearance, damage, breakage, etc. The effect of reducing the amount of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

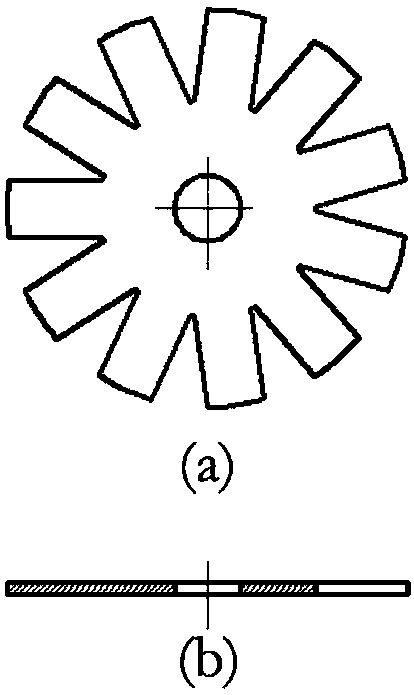

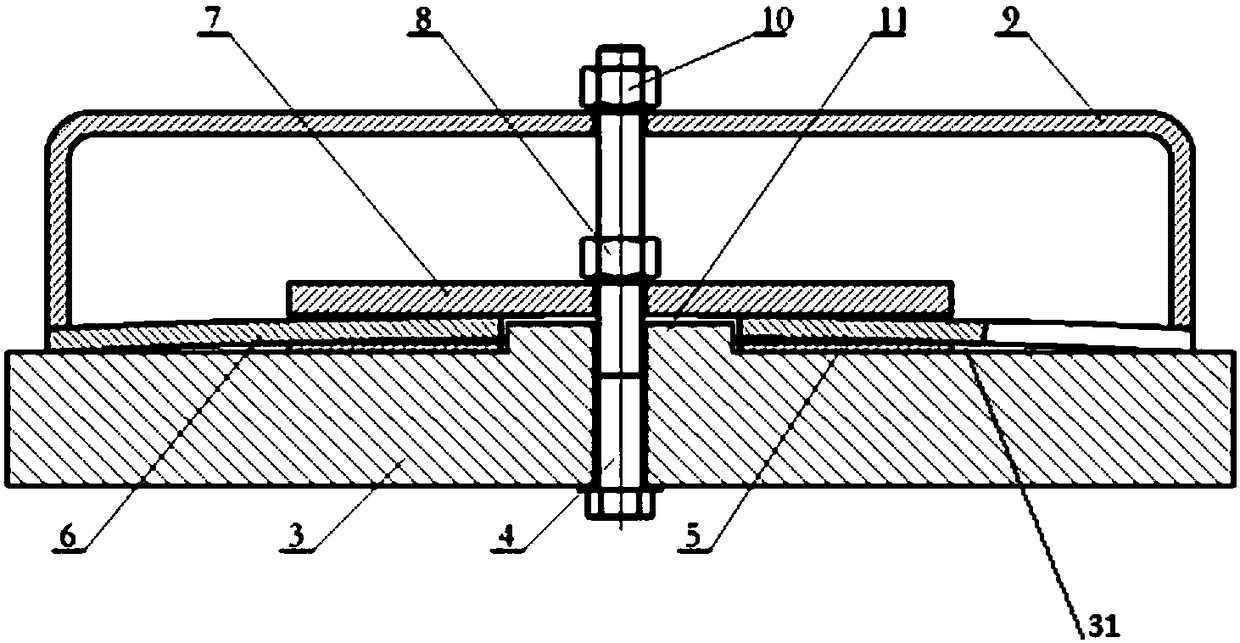

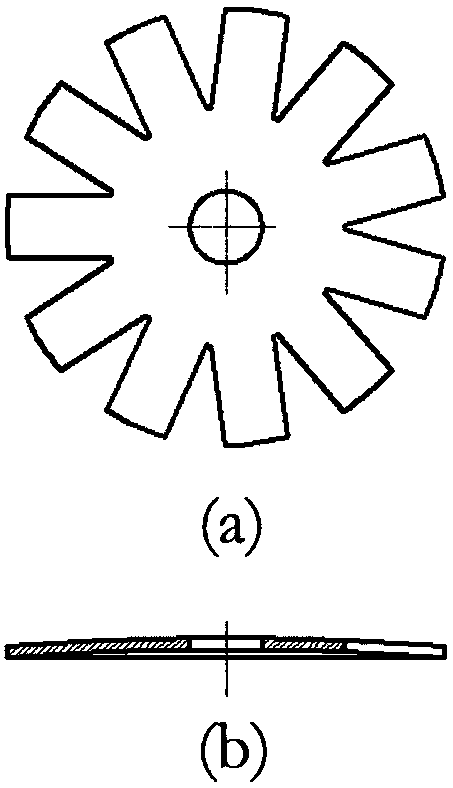

[0025] see Figure 1 to Figure 3 Shown, the molding process of the disc-shaped star wheel sheet of a kind of single-screw compressor of the present invention comprises the following steps:

[0026] (1) Molded star wheel blanks or cutting star wheel blanks such as figure 1 As shown, the star wheel blank is subjected to fine heat treatment or vibration treatment for internal stress relief;

[0027] (2) Process the inner hole, outer circle and upper and lower end faces of the star wheel according to the traditional process, and cut out the left and right sides of the rough machining teeth to ensure that the thickness of the processed star wheel is within the specified final processing size range, Ensure that the thickness difference of each part of the star wheel is not greater than 3 / 1000, and at the same time ensure that the flatness of the star wheel in the natural state is not greater than the tolerance precision level 7 specified in GB / T1184-1996;

[0028] (3) Process the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com