Air heat recovery device for printing equipment

A technology of printing equipment and air heat energy, which is applied in the field of air heat energy recovery devices for printing equipment, can solve the problems of energy waste and low heat utilization rate, achieve good laminar flow effect, reduce loss, and improve energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

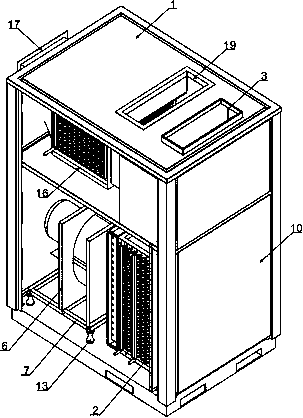

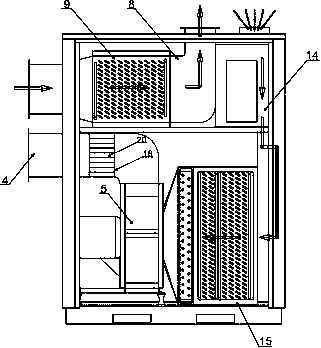

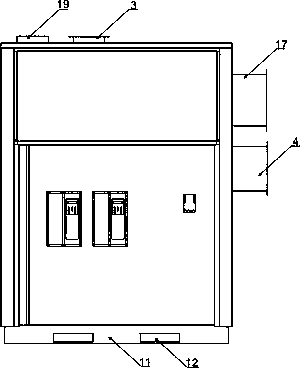

[0025] The invention provides an air heat recovery device for printing equipment, which includes a frame body 1; the inside of the frame body is divided into upper and lower cavities. There is a condensing heat exchanger 2 under the inside of the frame body, and a fan 5 installed on one side of the condensing heat exchanger to form a negative pressure. After negative pressure is formed at one end of the condensing heat exchanger 2, fresh air will be driven to be introduced from the fresh air outlet 3 And after being heated by the condensing heat exchanger, it is transported from the hot air pipe 4 to the fan inside the printing equipment that needs to be heated. The condensing heat exchanger can heat the fresh air, driven by the blower fan 5, it enters into other equipment that needs to heat the gas. A laminar flow pipe 18 is arranged in the hot air pipe 4, and a plurality of cylindrical laminar flow channels 20 are arranged in the laminar flow pipe. The value range of the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com