Method and device for measuring pressure resistance and compression modulus of discrete materials

A compressive modulus, bulk technology, applied in the measurement and analysis of rock and soil mechanical properties, geotechnical engineering field, can solve the problem of unmeasured bulk particle compressive strength and compressive modulus, rock and coal bulk compressive resistance and other problems such as rare research, to achieve the effect of fast and simple measurement method, wide research scope and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

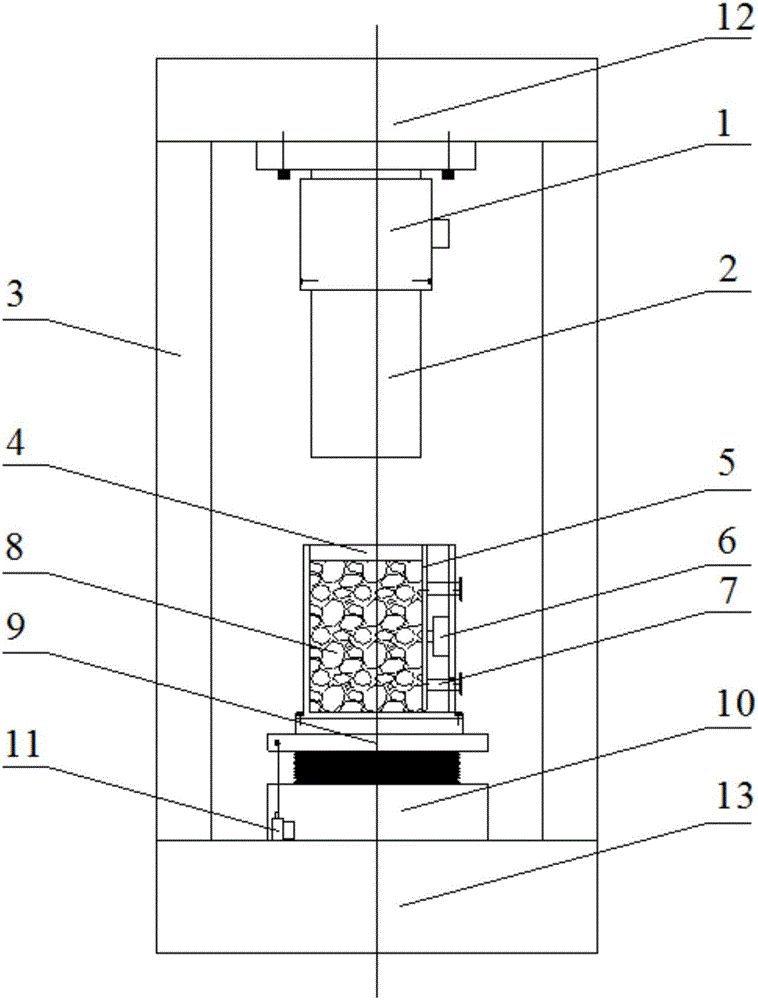

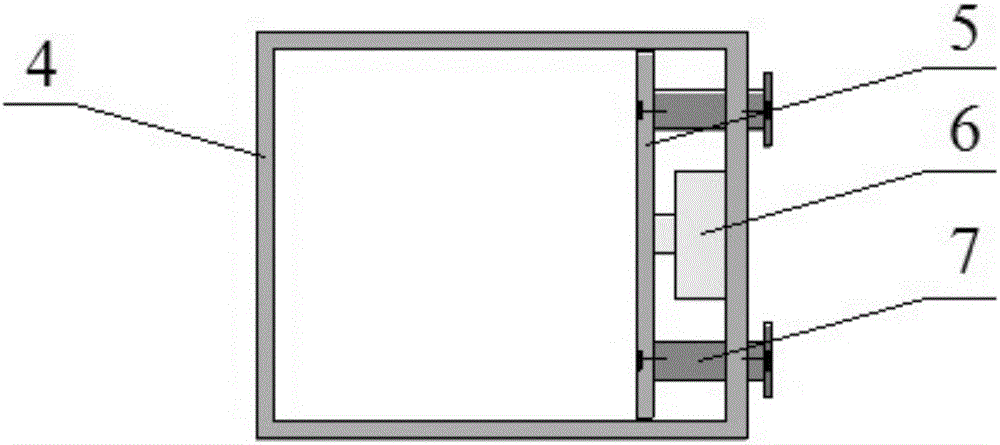

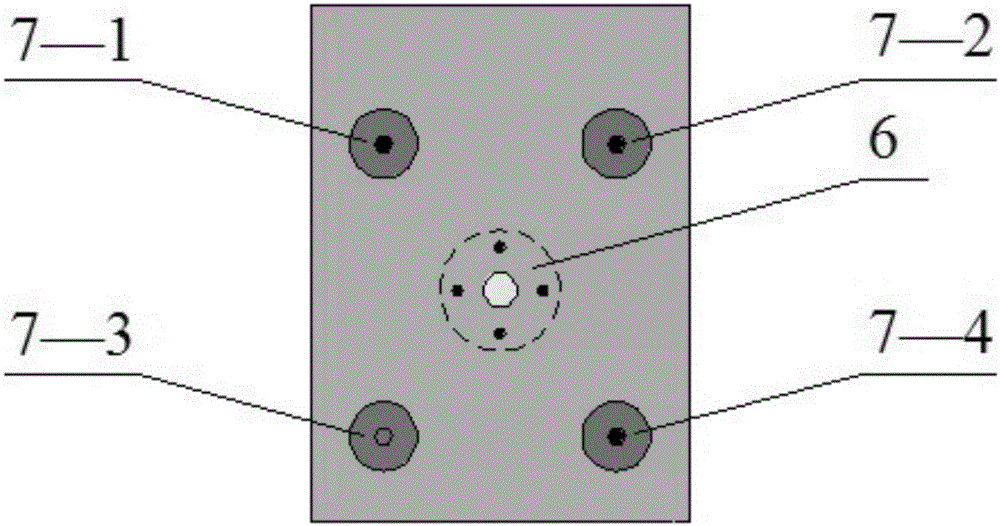

[0031] combined with Figure 1-3 Shown, a kind of compression resistance-compression modulus device of measuring bulk, it comprises load sensor 1, steel pressure column 2, support column 3, bulk storage bin 4, sliding baffle plate 5, pressure sensor 6, Guide rod 7, bulk material 8, bearing platform 9, driving device 10, displacement recorder 11, body top 12, body base 13 and control device (not shown). The top 12 of the machine body and the base 13 of the machine body are connected through the support column 3 and fixedly supported by the support column 3 . The bulk storage bin 4 is installed on the carrying platform 9 , the carrying platform 9 is installed on the driving device 10 , and the driving device 10 is installed on the body base 13 .

[0032] The upper opening of the bulk storage bin 4, the opening can pass through the steel pressure column 2, and at least one side wall of the bulk storage bin 4 is provided with a plurality of through holes, the through holes are eq...

Embodiment 2

[0041] This embodiment provides a method for measuring the compressive strength and compressive modulus of the bulk based on the device of the above-mentioned embodiment, comprising the following steps:

[0042] First, select several groups of bulk material 8-grain specimens in the bulk, measure the uniaxial compressive strength of each group of specimens on a uniaxial press, and take the average value as the uniaxial compressive strength of the bulk specimens of this material. Compressive strength, and as the maximum compressive ultimate strength of bulk material 8 during the compressive test;

[0043] Next, put the bulk material 8 into the bulk storage bin 4, the bulk material 8 has a lateral pressure effect on the sliding baffle 5, so that the sliding baffle 5 can be closely attached to the receiving end of the pressure sensor 6;

[0044] Again, turn on the computer information acquisition control system and the receiving device, lift the loading cylinder 10, and move the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com