A foot gold case and its production method, and tables including the gold case

A manufacturing method and watch case technology, applied in the field of watches, can solve the problems that pure gold watches are difficult to achieve mass production and market promotion, cannot meet the waterproof performance requirements of watches, and the fineness and value are not as good as pure gold watches, etc., so as to improve raw materials Utilization rate, solution to damage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

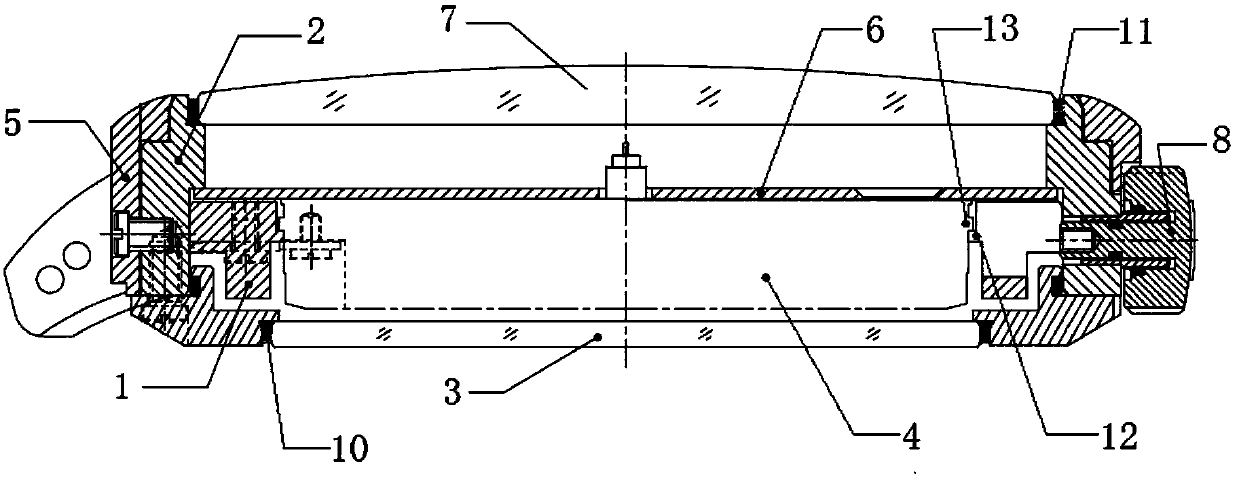

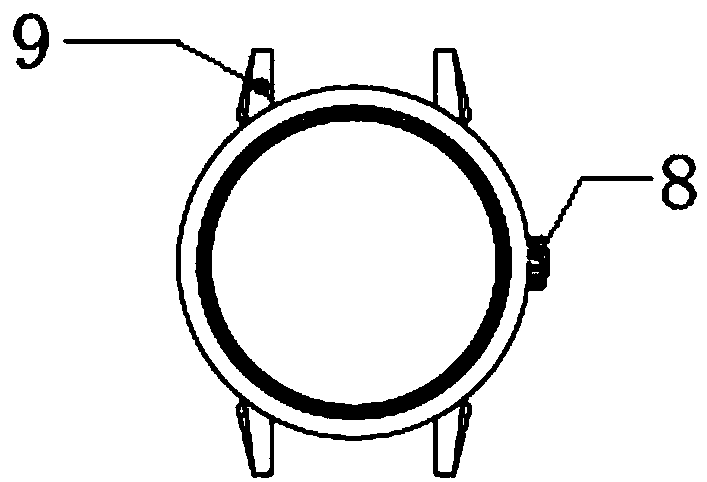

[0030] This embodiment provides a method for making a pure gold watch case, comprising the following steps:

[0031] (1) Raw material smelting: select 950 parts by weight of pure gold, 6.65 parts by weight of yttrium powder, 0.475 parts by weight of boron powder, 0.76 parts by weight of neodymium powder, 0.19 parts by weight of carbon powder, and 0.19 parts by weight of zirconium powder. The gold content is 999.3‰, and the particle size of the yttrium powder, boron powder, neodymium powder, carbon powder and zirconium powder is 5 μm. Place the above raw material components together in the crucible in the vacuum melting gold furnace, vacuumize the vacuum to keep the vacuum degree in the vacuum melting gold furnace at 0.04MPa, and use argon as the protective gas to control the raw material components in the crucible Carry out heating, raise the temperature of each raw material component in the crucible to 1200°C within 3 minutes, keep it for 7 minutes, so that the above raw mate...

Embodiment 2

[0042] This embodiment provides a method for making a pure gold watch case, the difference between it and the method for making a pure gold watch case provided in Example 1 is:

[0043] In step (1), after vacuuming, keep the vacuum in the vacuum melting furnace to be 0.05MPa;

[0044] When the stamping process is performed in step (3), a total of 2 stampings are performed, each time for 5 seconds, and the depth of each stamping is 0.5mm.

[0045] The remaining manufacturing methods and the structure of the watch including the solid gold case are the same as those provided in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com