Electromechanical system equipment health assessment method

An electromechanical system and health assessment technology, applied in the field of ship control, can solve the problems of large information redundancy, incompleteness, lack of status information, etc., to achieve the effect of satisfying information requirements, complete status information, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

[0041] According to a specific embodiment of the present invention, an equipment health assessment method for electromechanical systems is disclosed, such as Figure 6 As shown, it specifically includes the following steps:

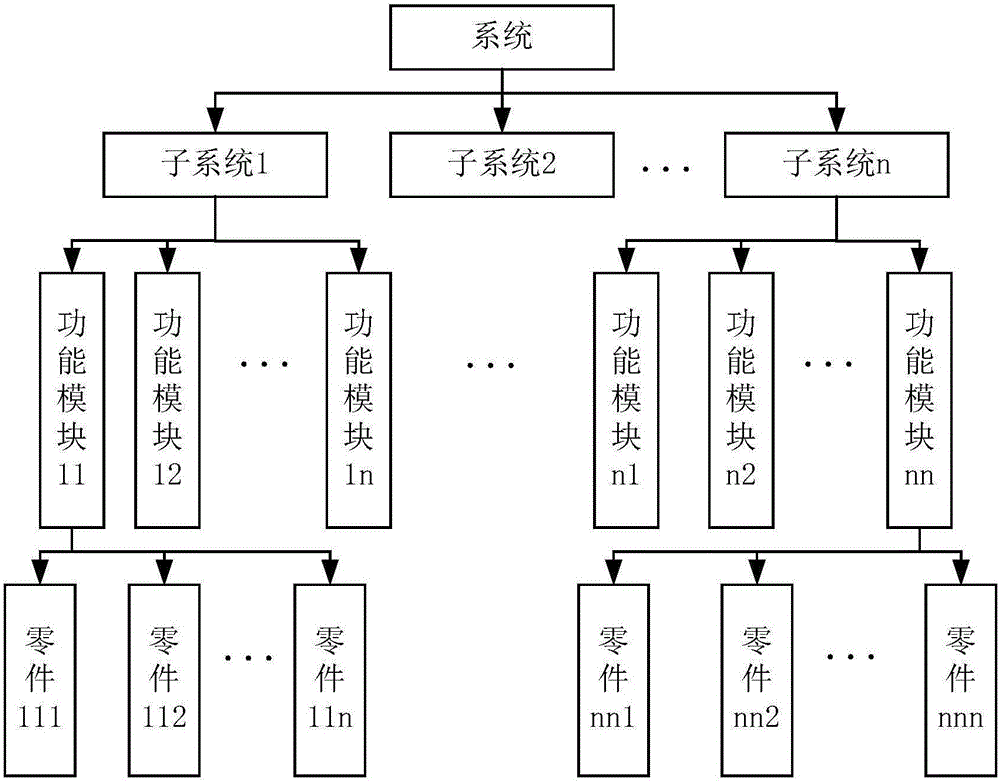

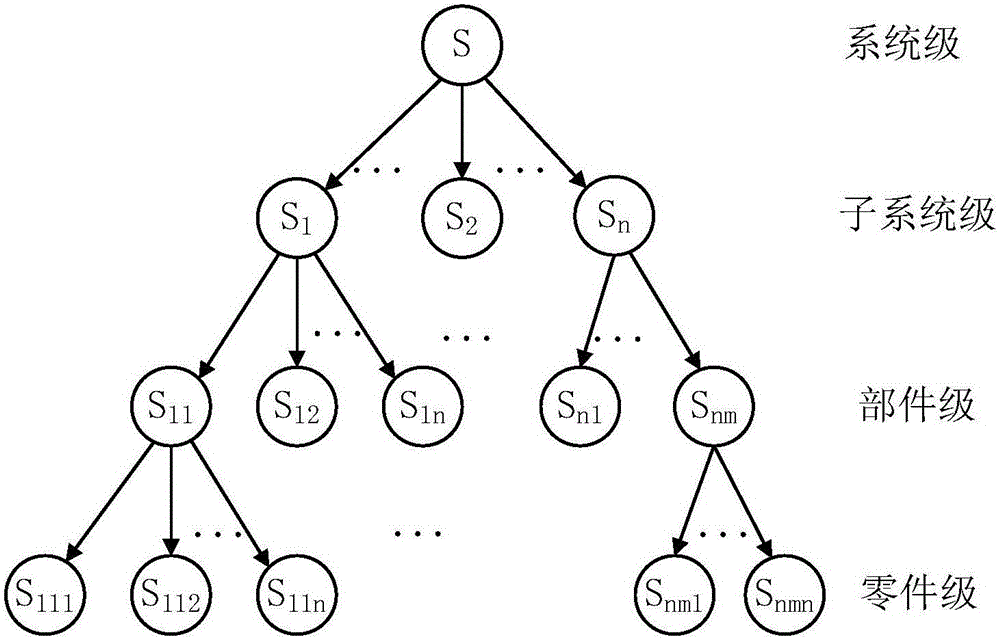

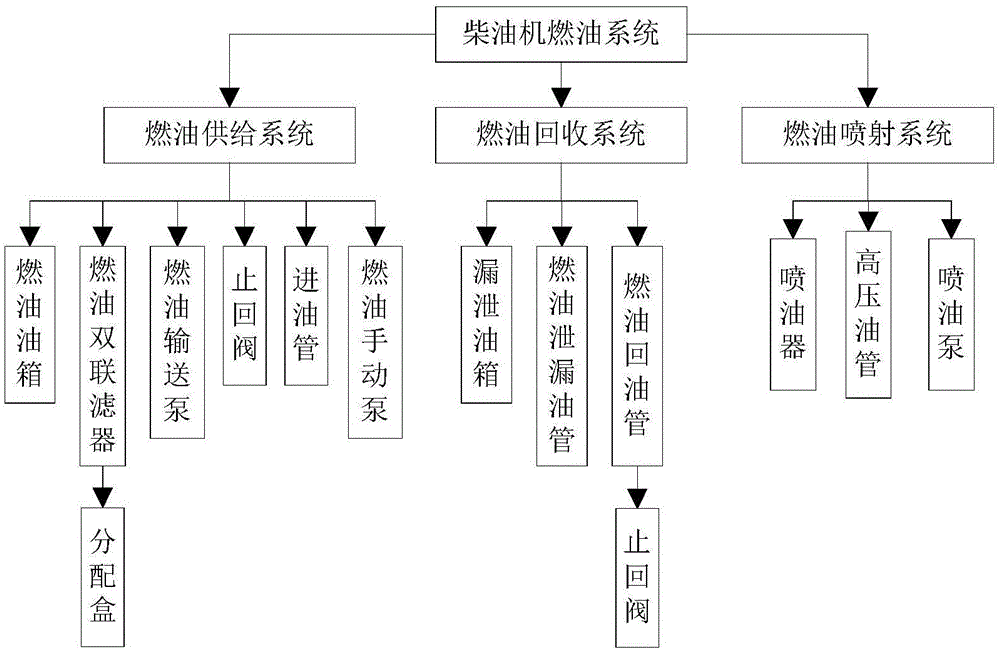

[0042] Step S1, according to the equipment characteristics, structural composition and functional composition of the electromechanical system, decompose the structure and function of the electromechanical system; and obtain the historical operating parameters of each sub-component.

[0043] Because for different parameters, when performing fault diagnosis, it is necessary to diagnose from the structure / function. Therefore, when com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com