Container for radioactive inventory and method of making same

A radioactive and container technology, applied in the field of containers containing radioactive materials, can solve the problems of cost, sacrifice of container cover stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

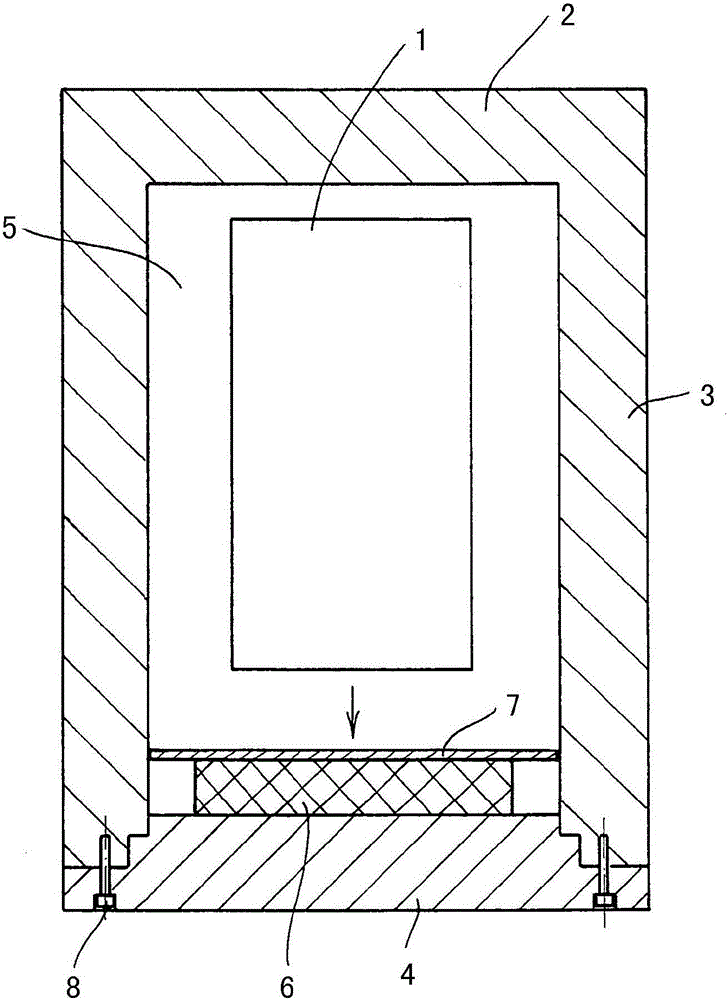

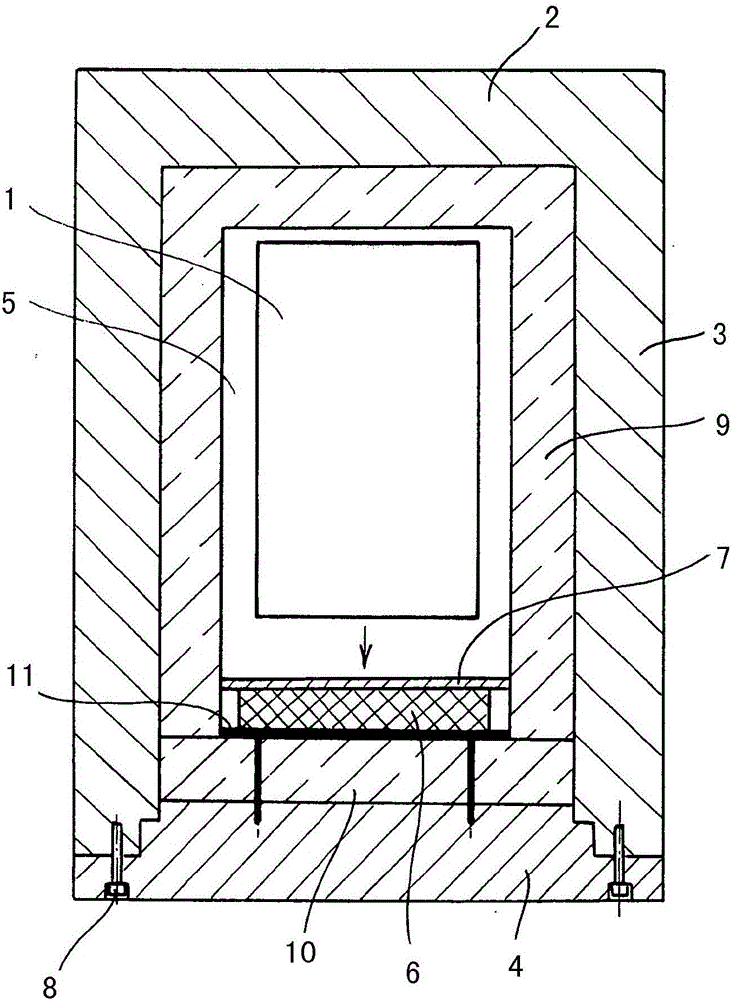

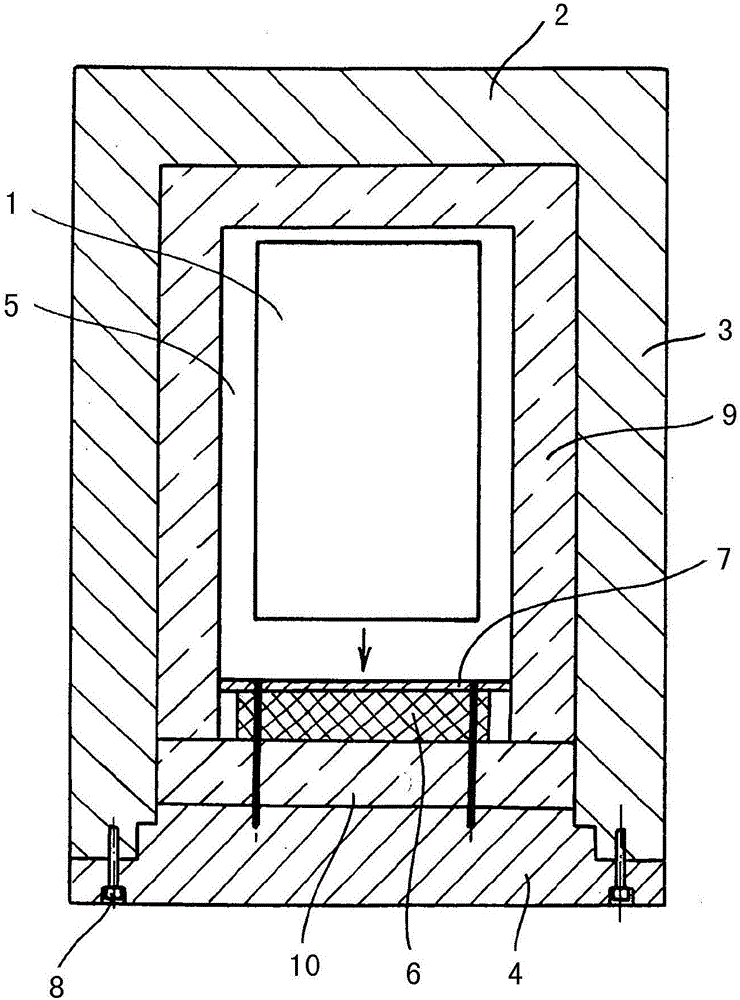

[0031] figure 1 A container according to the invention is shown in , which has a container bottom 2 , a container peripheral wall 3 and a container lid 4 . The container is designed as a hollow cylinder and surrounds an interior 5 in which only the radioactive material 1 indicated by the symbol is located. The container is shown upside down in order to illustrate the state of the lid falling flat. At the moment of impact on the solid ground, the object 1 hits the container lid 4 with a time delay, so that a high force acts on the container lid 4 . The container cover 4 is connected to the container peripheral wall 3 through 24 threaded connections 8 in the form of M36 screw parts. The vessel walls 2, 3, 4 consist of cast iron of grade (quality) GGG 40. The container peripheral wall 3 has a thickness of 160 mm, whereas the container bottom 2 and the container lid 4 have a thickness of 180 mm each. The hollow cylindrical interior 4 has a height of 1140 mm and a diameter of 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com