Polymer composition by continuous filler slurry extrusion

A polymer and composition technology, applied in the field of continuous production of polymer compositions, can solve the problems of high cost and discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0260] Example 1 - Production of Polymer Compositions (Comparative Example) :

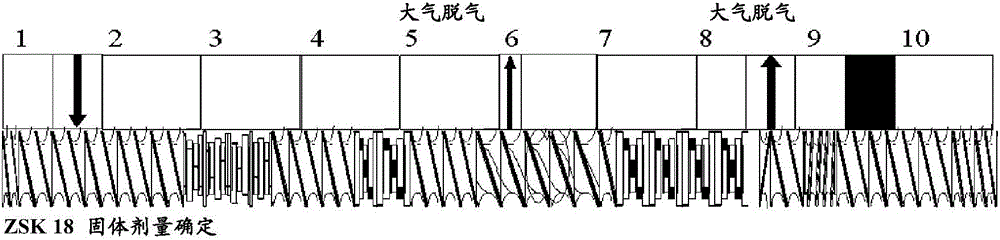

[0261] LLDPE was supplied to the feed area of an extruder (Coperion ZSK-18, Coperion GmbH, Germany) with the following configuration:

[0262]

[0263] cylinder:

[0264] Numbering

Cartridge type

1

supply

2

3

4

5

solid

6

Composite barrel 18 / 18

7

solid

8

9

exhaust pipe (closed)

10

end barrel

[0265] Screw configuration:

[0266] quantity

Types of

1

Conveying element 12 / 12

5

Conveying elements 24 / 24

1

Kneading element KB45 / 5 / 16N-3FE

2

Kneading element KB45 / 5 / 16 3FE

1

Kneading element KB45 / 5 / 16 3FE-N

1

Conveying element 24 / 12

2

Conveying elements 24 / 24

1

Kneading element KB45 / 5 / 16

1

Kneading element KB45 / 5 / 24

2

Conveying elements 24 / 24...

Embodiment 2

[0275] Example 2 - Production of Polymer Compositions (Comparative Example) :

[0276] LLDPE was supplied to the feed zone of an extruder (Coperion ZSK-18, Coperion GmbH, Germany) having the configuration described in Example 1 . By using the side feeder of the extruder, the coated calcium carbonate powder ( 95T-OM) into the extruder and mixed with the polymer melt prior to discharge and pelletization.

[0277] The following samples were obtained as pellets:

[0278] Sample serial number

4

5

6

Filler content [wt%]

10

30

60

FPV[bar·g –1 ]

1.0

0.8

0.9

Ash content[%]

9.6

29.4

58.5

Moisture content [ppm]

n.d.

n.d.

855

extrusion simulation [bar]

n.d.

n.d.

30

[0279] Table 2. Filler Content, Filtration Pressure Value (FPV), Ash Content and Moisture Content of Comparative Samples 4-6.

[0280] For the production of sample 6, the screw speed was reduced to 550min –1 .

Embodiment 3

[0281] Example 3 - Production of polymer compositions (invention) :

[0282] LLDPE was supplied to the feed area of an extruder (Coperion ZSK-18, Coperion GmbH, Germany) with the following configuration:

[0283]

[0284] cylinder:

[0285] Numbering

Cartridge type

1

supply

2

solid

3

solid

4

solid with outgassing

5

solid

6

Composite barrel 18 / 18

7

solid

8

9

exhaust pipe (closed)

10

end barrel

[0286] Screw configuration:

[0287] quantity

Types of

1

Conveying element 12 / 12

4

Conveying elements 24 / 24

1

Kneading element KB45 / 5 / 16N-3FE

2

Kneading element KB45 / 5 / 16 3FE

1

Kneading element KB45 / 5 / 16 3FE-N

1

Kneading element 90 / 5 / 16

1

Conveying elements 24 / 24

2

Conveying element 16 / 16

1

spacer / 1

1

ZME 6 / 11

1

spacer / 1

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com