Flame-retardant cellulose ester preparations

A technology of cellulose ester and cellulose, applied in the field of cellulose ester preparation, can solve the problems of flame-retardant plasticizers, such as unfavorable human beings and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0069] Parts hereinafter are by weight.

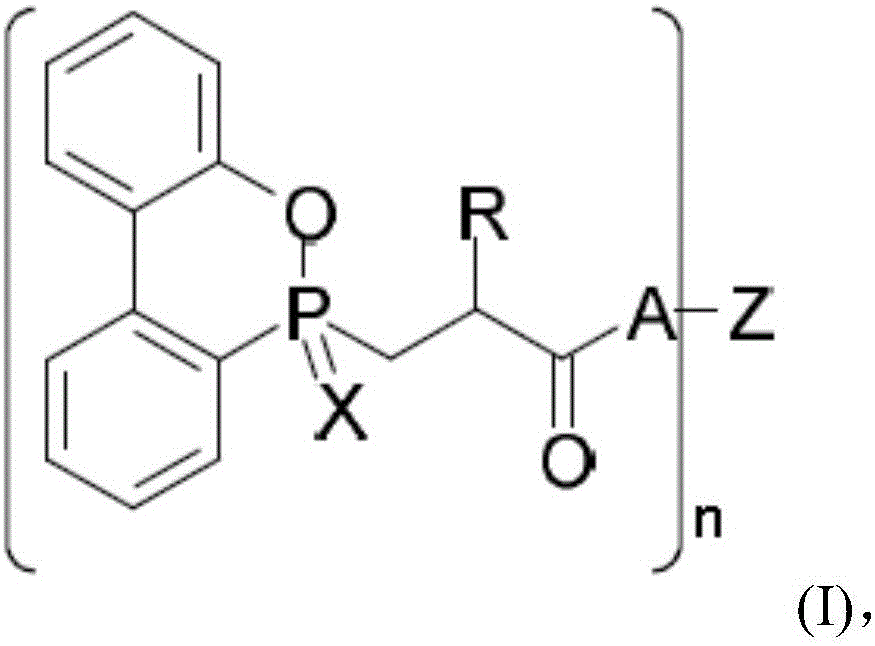

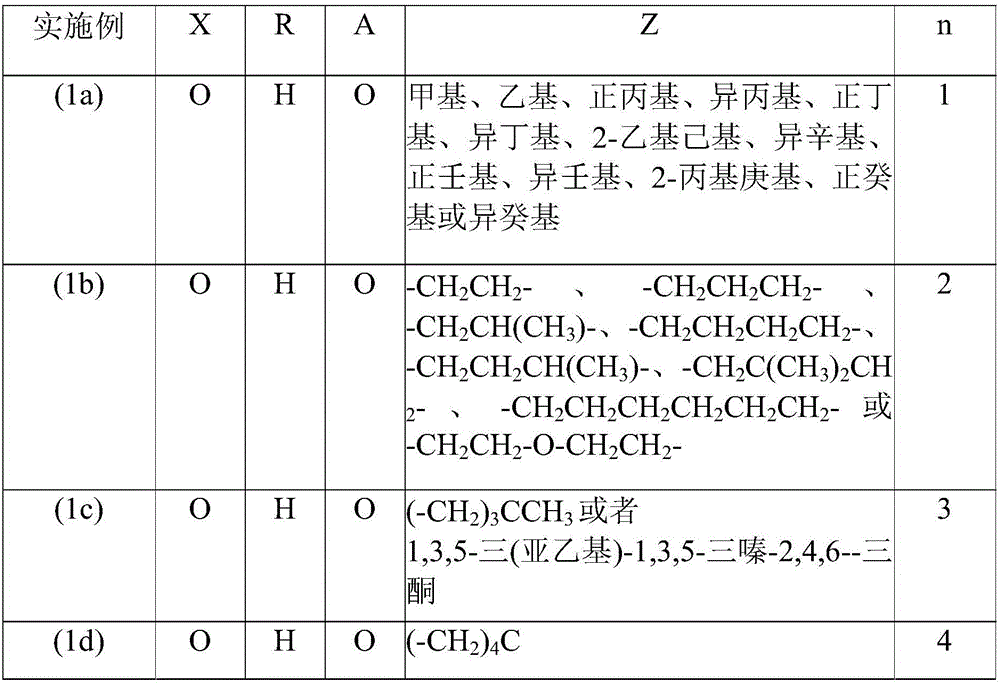

[0070] Preparation of phosphopropionates of formula (I) wherein X=O, R=H, A=O, Z=n-butyl and n=1

[0071] n-Butyl 6-oxo-6H-dibenzo[c,e][1,2]oxaphosphazene-6-propionate was prepared according to Organic Letters (Organic Letters) 2005, Vol. 7, No. 5 period, Supplementary Information S8 prepared by reacting 6H-dibenzo[c,e][1,2]oxaphosphapine 6-oxide with n-butyl acrylate to obtain a colorless A liquid having a viscosity of 6500 mPas at 23°C.

[0072] Production of cellulose ester formulations

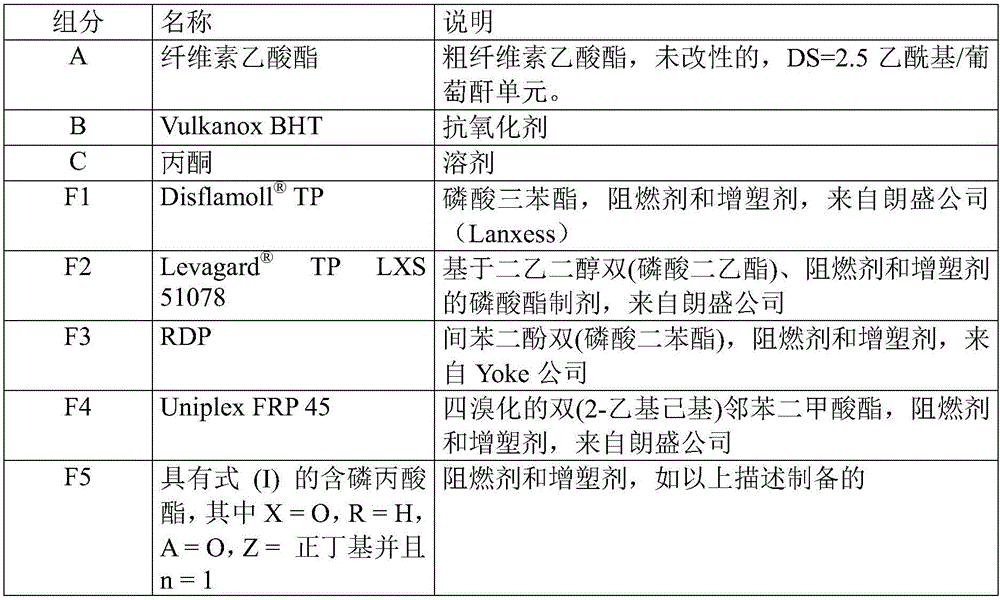

[0073] Table 1: Raw materials for the production of cellulose ester preparations

[0074]

[0075] Production of solutions of cellulose ester formulations

[0076] Solvents, flame retardants and antioxidants were initially charged in glass flasks in the quantitative ratios reported in Table 2 according to Table 1 . The amount of cellulose acetate powder reported in Table 2 was added with constant agitation as the glass flask was gently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com