Cutting device for solder strip

A technology of cutting device and welding strip, applied in shearing device, accessories of shearing machine, shearing machine equipment, etc., can solve the problems of inconsistent cutting position, deviation of cutting position, scratches of battery string aluminum back field, etc. The effect of cutting accuracy and ensuring transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

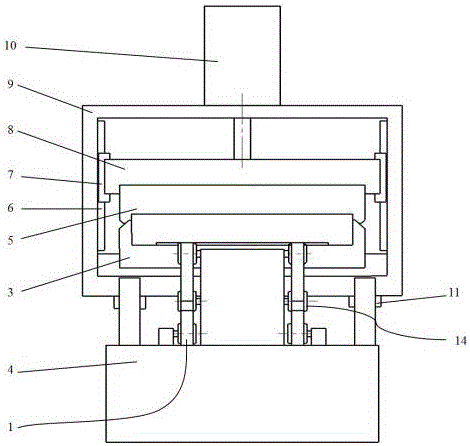

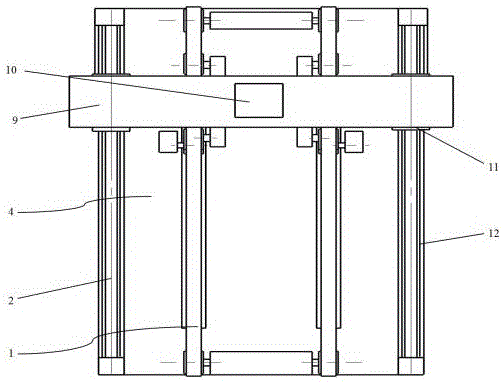

[0022] Such as Figure 1-Figure 4 As shown, a welding ribbon cutting device includes a base 4, a conveying mechanism, and a cutting mechanism, wherein the conveying mechanism and the cutting mechanism are installed on the base 4.

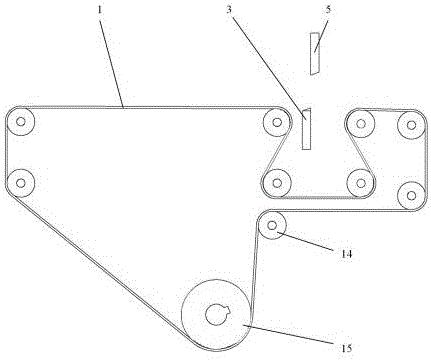

[0023] The conveying mechanism includes a conveyor belt 1, a driven wheel set 14, a driving wheel 15, and a servo motor, wherein the conveyor belt 1 winds around several driven wheel sets 14 and the driving wheel 15, and the conveyor belt 1 forms an input part and an output part. , the output end of the servo motor is connected to the driving wheel 15, and the servo motor is provided with an encoder for detecting the number of rotations of the motor. Therefore, under the drive of the servo motor, the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com