Rotary automatic mechanical arm

A technology of manipulator and manipulator, applied in the field of automation, can solve the problems of high manufacturing cost, rising cost, complex structure, etc., and achieve the effect of improving product yield, improving work efficiency and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

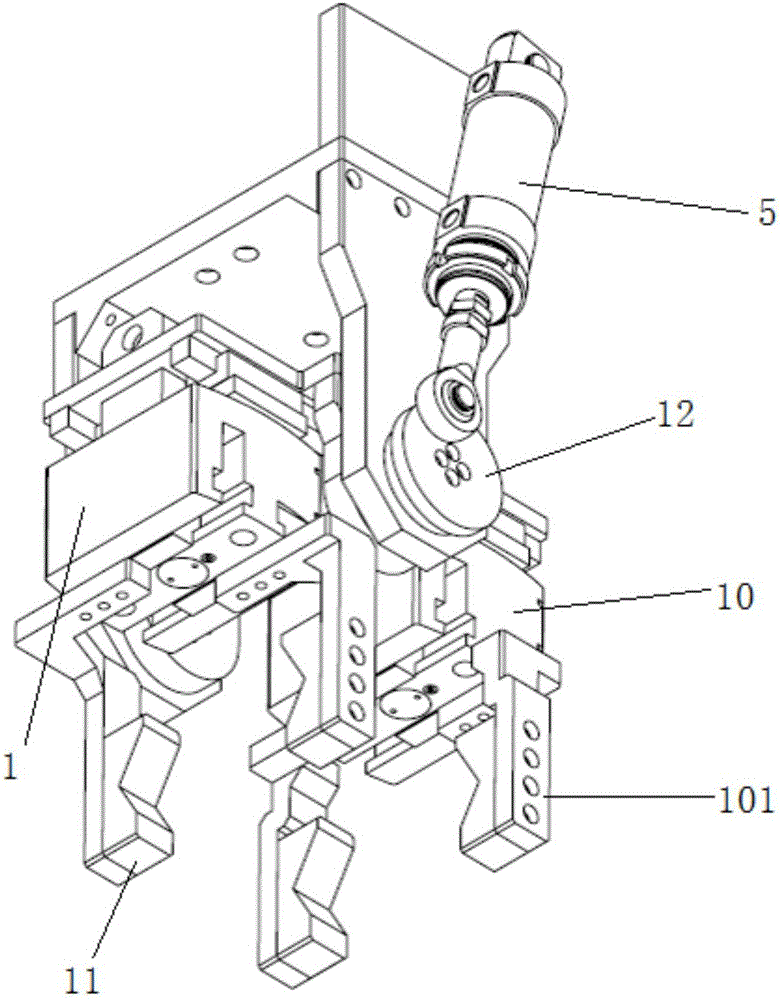

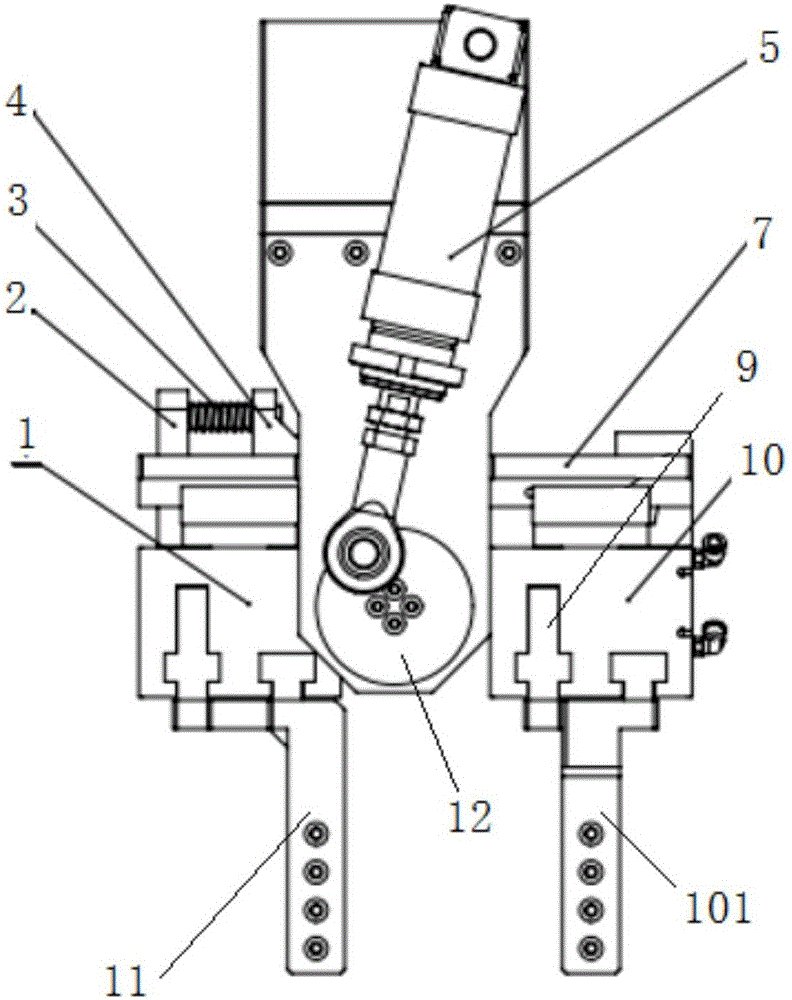

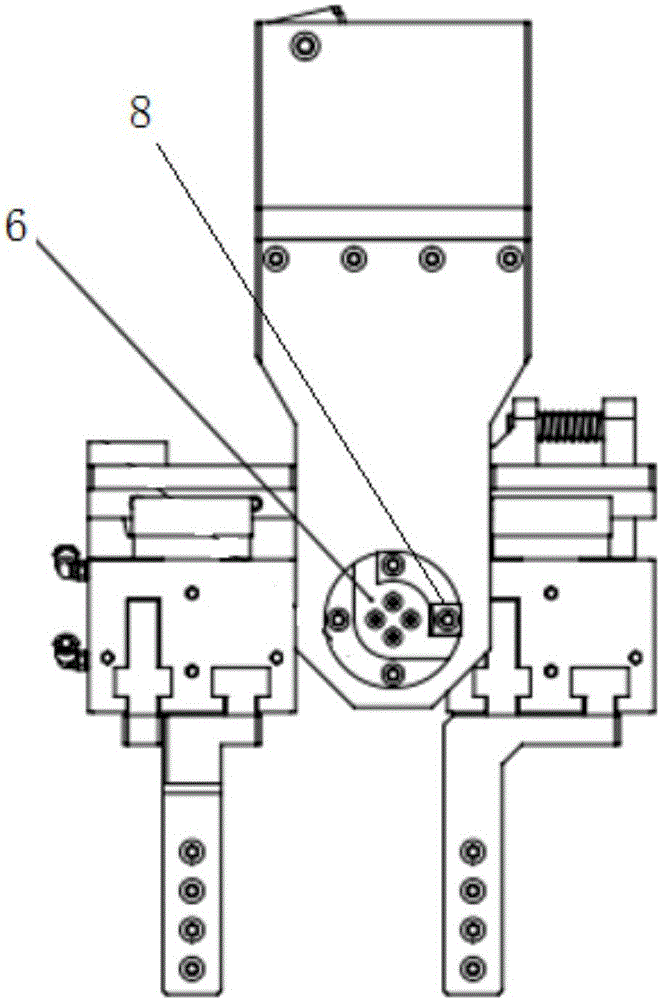

[0023] A rotatable automatic manipulator, its structure is as follows figure 1 , figure 2 and image 3 As shown, the manipulator includes a cylinder 5, a mounting plate 7, an L-shaped bumper 6, a fixed air gripper 10 and a follower air gripper 1, the upper end of the fixed air gripper 10 is connected to one side of the installation plate 7, and the upper end of the follower air gripper 1 Slidingly connected to the other side of the mounting plate 7, the inner side of the fixed claw runs through a rotating shaft and can rotate synchronously with the rotating shaft, one end of the rotating shaft is connected to the cylinder 5 through the turntable 12, and the center of the rotating shaft is fixedly connected to the turntable 12 , the cylinder 5 is fixedly connected to the outside of the turntable; the other end of the rotating shaft is provided with a positioning block 8 that matches the collision block 6, and the positioning block 8 can move in an arc between the two sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com