Box-packed article transportation cart for chemical engineering places

A boxed object and place technology, applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems that affect the overall appearance and scratches of boxed objects, and achieve the effects of avoiding direct contact, convenient operation, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

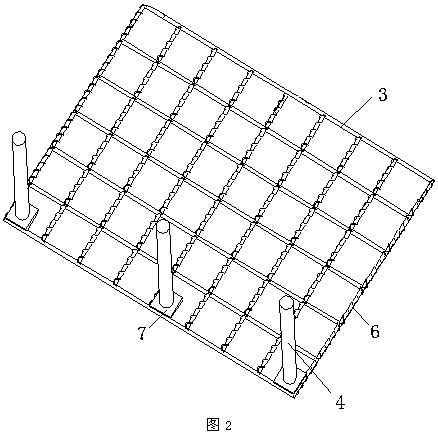

[0017] See figure 1 and figure 2 , the present invention has vehicle frame 1; Universal wheel 2 is installed under vehicle frame 1; Hollow-out support, the two corners of one side of the shelf 3 are hinged on the frame 1, and the support columns 4 are fixed under the two corners of the other side, and the horizontal and vertical grid connecting pipes of the shelf 3 are wound with insulation Strip 6. The hinged end of the layer frame 3 and the vehicle frame 1 is also provided with some springs 5 for rotating the layer frame 3 upwards; the two ends of each spring 5 are connected to the layer frame 3 and the vehicle frame 1 respectively. A square support plate 7 is welded on the lower end surface of each support column 4 .

[0018] During the use of the present invention, the boxed objects are placed on the bottom shelf 3; Turn down to the vertical state to reduce the occupied space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com