Bobbin for spinning

A bobbin and side disk technology, applied in the bobbin field, can solve the problems of textile thread winding, single function, and reduced work efficiency, and achieve good insulation, high mechanical strength, and increased color sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

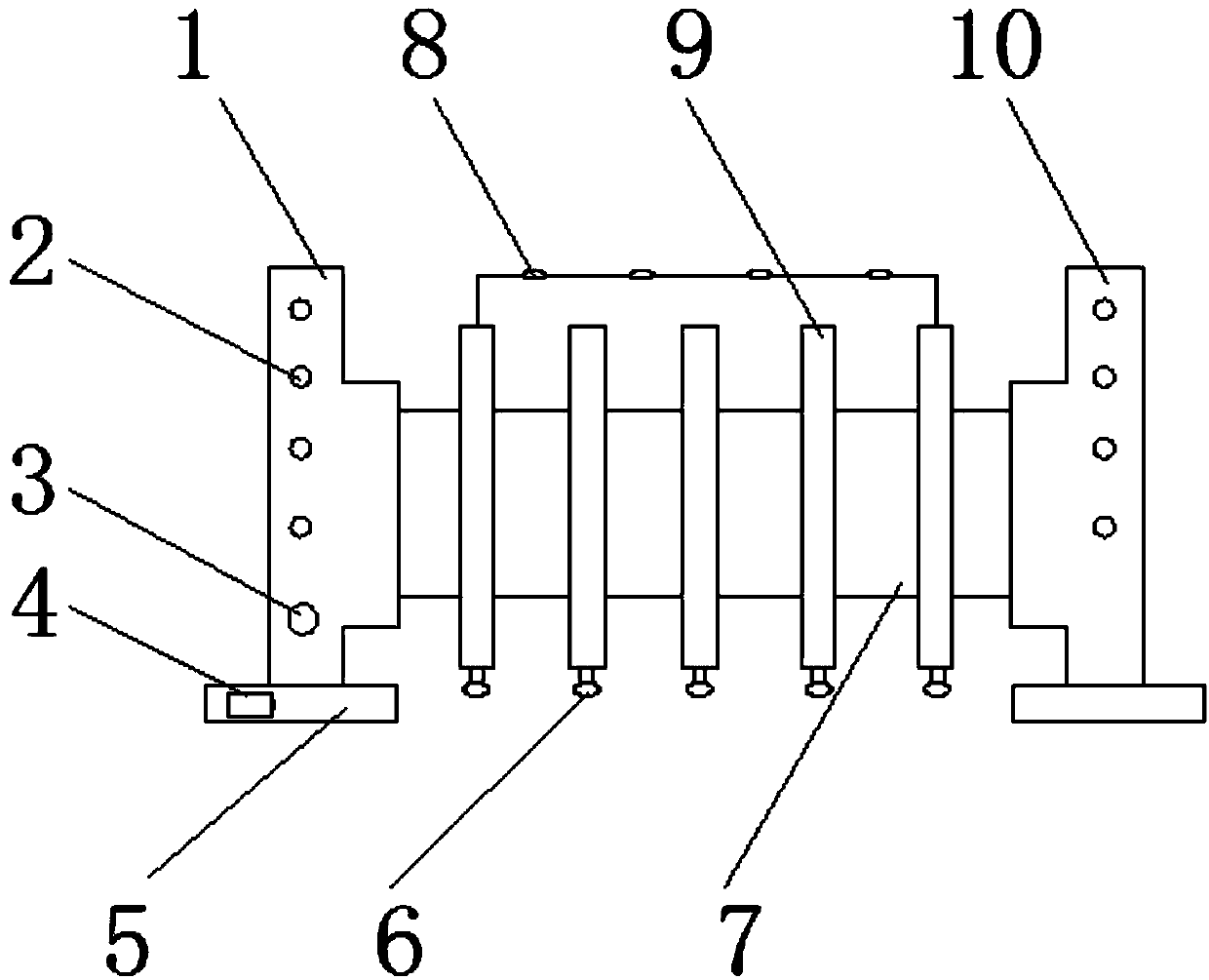

[0017] Example: see figure 1 , a bobbin for textile use in the present invention, comprising a side plate A1, said side plate A1 is rotationally connected with a side plate B10 through a rotating shaft 7, said side plate A1 and side plate B10 are provided with colorful lights 2, said The bottom of the colorful lamp 2 is provided with a switch button 3, the side plate A1 is fixedly connected with the base 5, the inside of the base 5 is provided with a battery 4, and the rotating shaft 7 is provided with several baffles 9, and the rotating shaft 7 is connected to the baffle. The board 9 is slidably connected, the top of the baffle 9 is provided with a wire hole 8 , the bottom of the baffle 9 is provided with an adjustment button 6 , and the battery 4 is electrically connected to the colorful light 2 through the switch button 3 .

[0018] Both the side plate A1 and the side plate B10 are made of phenolic plastics, which have high mechanical strength, good insulation, heat resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com