An organic-inorganic hybrid magnesium hexamethylene phosphonate flame retardant and its preparation method

A technology of magnesium hexamethylene phosphonate and melamine hexamethylene phosphonic acid, which is applied in the field of flame retardants, can solve the problems of easy volatilization, low decomposition temperature, and large smoke generation, and achieve good smoke suppression effect, good compatibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 1 L of deionized water as a solvent into a reaction vessel equipped with a stirring device, a thermometer and a reflux condensing device, and then add 0.69 kg (1 mol) of melamine hexamethylene phosphonic acid, stir and slowly raise the temperature to 50°C. Slowly add 0.12 kg (2 mol) of magnesium hydroxide into the reactor in batches, and keep the reaction for 8 hours. After the solution was cooled, absolute ethanol was added and stirred for 4 h, then left to stand overnight and then suction filtered. Washing with 5wt% hydrochloric acid aqueous solution for 2-3 times, then washing with absolute ethanol for 3-4 times, and finally vacuum-drying to obtain 0.44 kg of white solid, namely the organic-inorganic hybrid magnesium hexamethylene phosphonate flame retardant.

Embodiment 2

[0027] Add 2.5L of deionized water as a solvent into a reaction vessel equipped with a stirring device, a thermometer and a reflux condensing device, then add 1.38 kg (2 mol) of melamine hexamethylene phosphonic acid, stir and slowly raise the temperature to 55°C. Slowly add 0.35 kg (6 mol) of magnesium hydroxide in batches into the reactor, and keep it warm for 10 hours. After the solution was cooled, absolute ethanol was added and stirred for 5 h, then left to stand overnight and then suction filtered. Wash with 7wt% hydrochloric acid aqueous solution for 2-3 times, then wash with absolute ethanol for 3-4 times, and finally vacuum-dry to obtain 1.47 kg of white solid of hexamethylene phosphonate magnesium flame retardant.

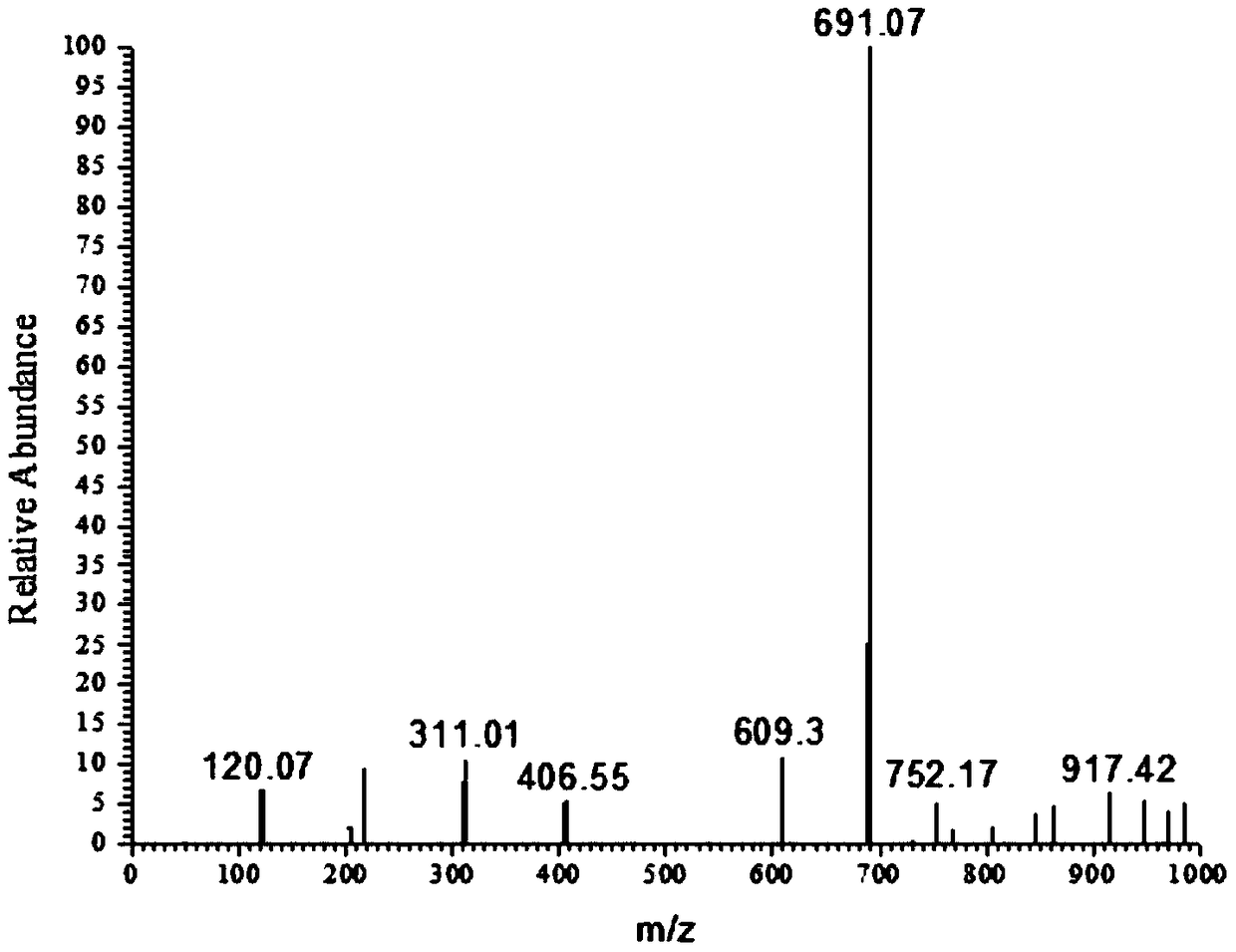

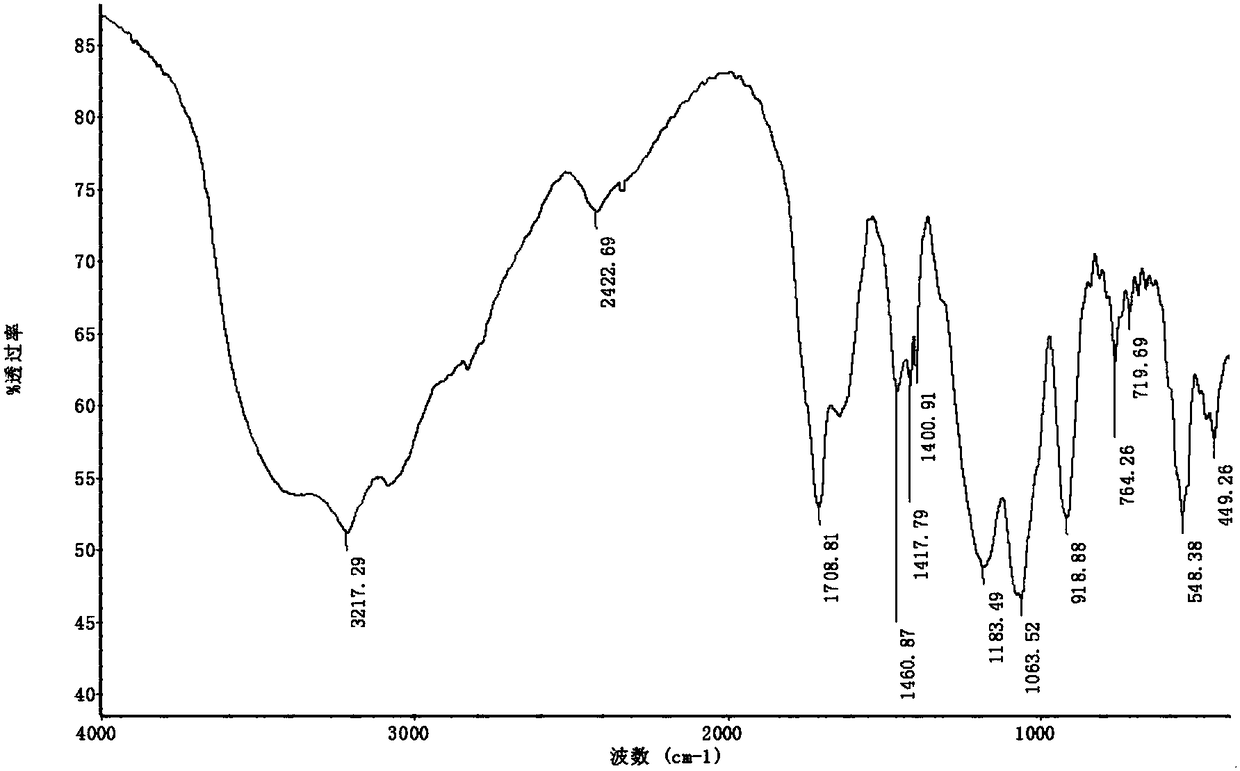

[0028] We have carried out infrared spectroscopic analysis to the white solid that embodiment 2 makes, and the result is as follows figure 2 shown. from figure 2 It can be seen in 3217.29cm -1 It is the stretching vibration absorption peak of -OH, 2...

Embodiment 3

[0030] Add 3L of deionized water as a solvent into a reaction vessel equipped with a stirring device, a thermometer and a reflux condensing device, then add 2.07 kg (3 mol) of melamine hexamethylene phosphonic acid, stir and slowly raise the temperature to 60°C. Slowly add 0.7kg (12mol) of magnesium hydroxide into the reactor in batches, and keep the temperature for 12 hours. After the solution was cooled, absolute ethanol was added and stirred for 6 h, then left to stand overnight and then suction filtered. Washing with 8 wt% hydrochloric acid aqueous solution for 2-3 times, then washing with absolute ethanol for 3-4 times, and finally vacuum-drying to obtain 2.06 kg of white solid of hexamethylene phosphonate magnesium flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com