Vacuum carburizing furnace for automatically controlling furnace atmosphere and control method

A technology of vacuum carburizing and furnace atmosphere, applied in non-electric variable control, flow control, control/regulation system, etc., can solve the problems of reducing labor intensity of craftsmen, complicated calculation, and unstable heat treatment quality repeatability, etc. The effect of accurate and reliable measurement value, high adjustment precision and good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

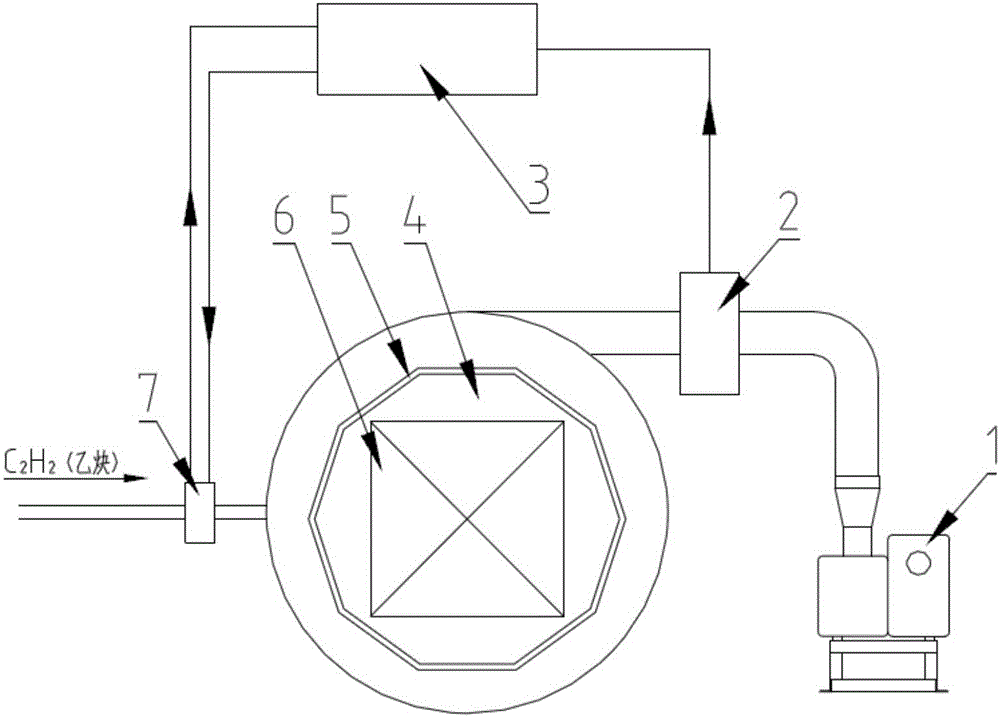

[0031] like figure 1 As shown, a vacuum carburizing furnace that automatically controls the atmosphere in the furnace includes a reaction chamber 4 for placing a target workpiece 6, a vacuum pump group 1 connected to the reaction chamber 4 and a gas supply pipeline, and the vacuum carburizing furnace also includes an atmosphere The measuring device 2, the control device 3 and the metering device 7, the atmosphere measuring device 2 is connected with the reaction chamber 4, the metering device 7 is arranged on the gas supply pipeline, and the metering device 7 is used to adjust and calculate the gas feeding time and the progress of the gas supply pipeline. Gas volume, the control device 3 is respectively connected with the atmosphere measuring device 2 and the metering device 7, and the gas supply pipeline leads into C 2 h 2 (acetylene);

[0032] The atmosphere measurement device 2 measures the gas composition and relative content in the reaction chamber 4, and transmits the ...

Embodiment 2

[0041] A method for automatically controlling the atmosphere of a vacuum carburizing furnace, comprising the following steps:

[0042] S1, using the atmosphere measuring device to measure the gas composition and relative content in the reaction chamber 4, and transmit the measurement result to the control device 3 in real time;

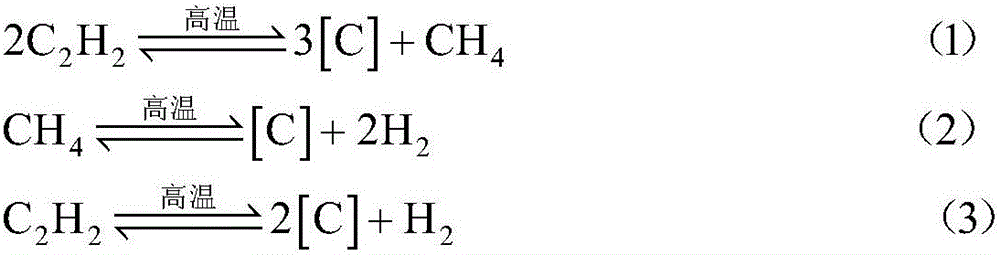

[0043] S2, the control device 3 calculates the real-time enrichment rate of the surface of the workpiece according to the measurement results of the atmosphere measuring device 2 and the metering data of the metering device 7. The metering device 7 is arranged on the gas supply pipeline of the vacuum carburizing furnace, and the metering data includes the reaction chamber 4 The length of time for the gas to pass through;

[0044] S3, the control device 3 controls the opening and closing of the gas supply pipeline to adjust the atmosphere in the furnace according to the real-time enrichment rate of the surface of the target workpiece 6, and returns to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com