Apparatus and method for blanking steel strand stably and accurately on deck

A steel strand, accurate technology, applied in the direction of bridge materials, bridges, bridge construction, etc., can solve the problems of construction difficulty and difficulty, and achieve the effect of ensuring the working length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

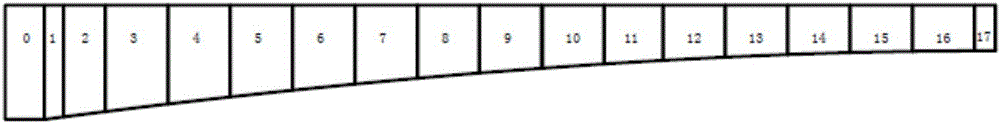

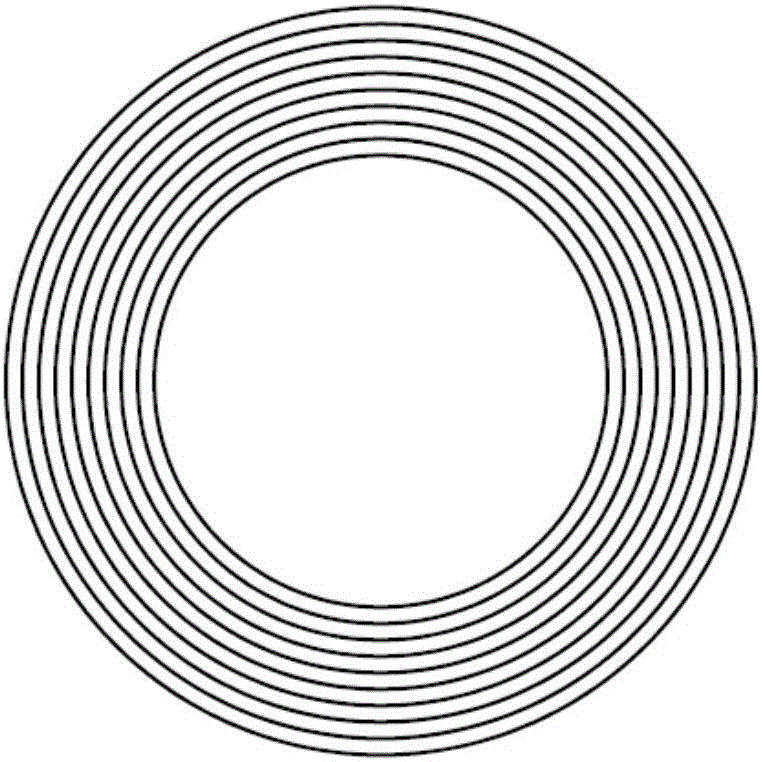

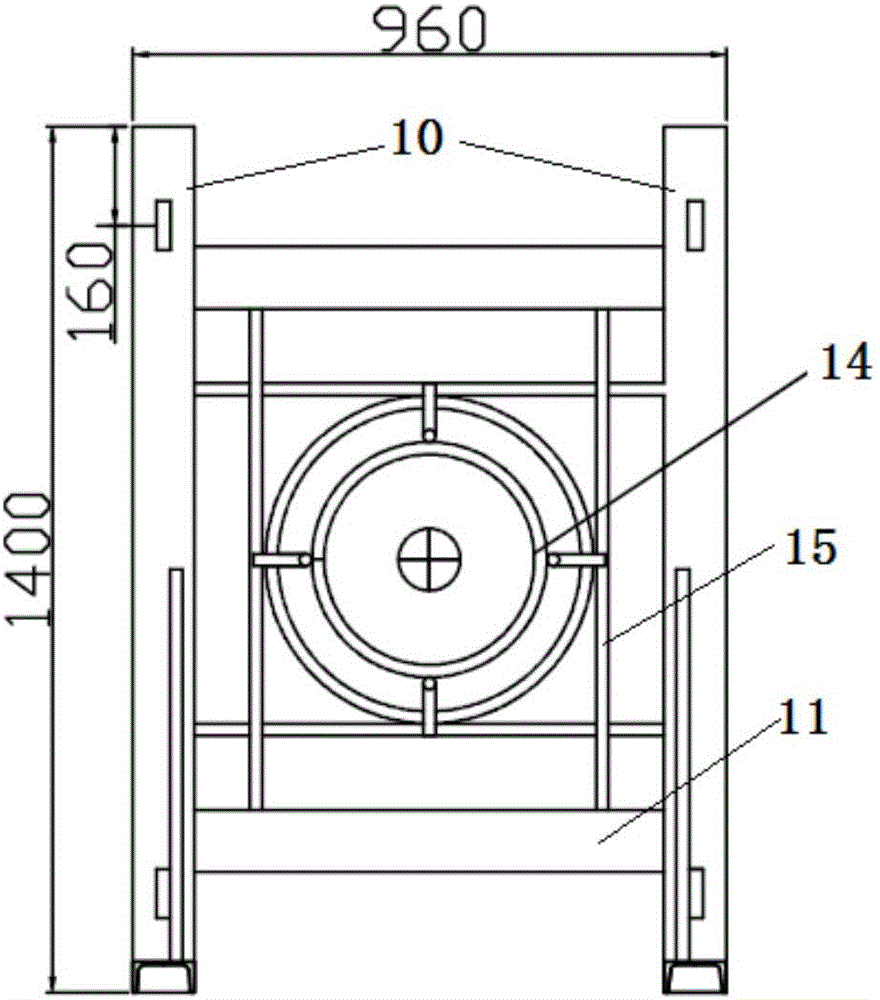

[0042] like Figure 1 to Figure 19 As shown, a device for stably and accurately cutting steel strands on the bridge deck, including steel strands 1, fixed frame 2, pad beam 3, fixed pulley 4, grinding wheel cutter 5, vertical steel bars 6, etc.

[0043] like Figure 16 to Figure 19 As shown, the steel strand 1 is fixed on the bridge deck through the fixed frame 2, and a restraint ring 14 is provided on one side of the fixed frame 2; a pad beam 3 for hanging basket construction is set at 3m in front of the steel strand 1 release end, and the pad Beam 3 is provided with a The fixed pulley 4 is arranged on the top of the front end of the newly poured concrete A, and a grinding wheel cutter 5 is set at the boundary between the new concrete A and the old concrete B poured to the direction of the newly poured concrete A at 2.2m, and the new concrete Set the vertical steel bar 6 at the boundary between A and old concrete B poured at 0.5m from the old concrete B poured.

[0044] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com