Early-detach jack for supporting building formwork

A building formwork and jacking technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of high construction cost, long turnover period of building formwork, and inability to realize early demolition, etc., reaching the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

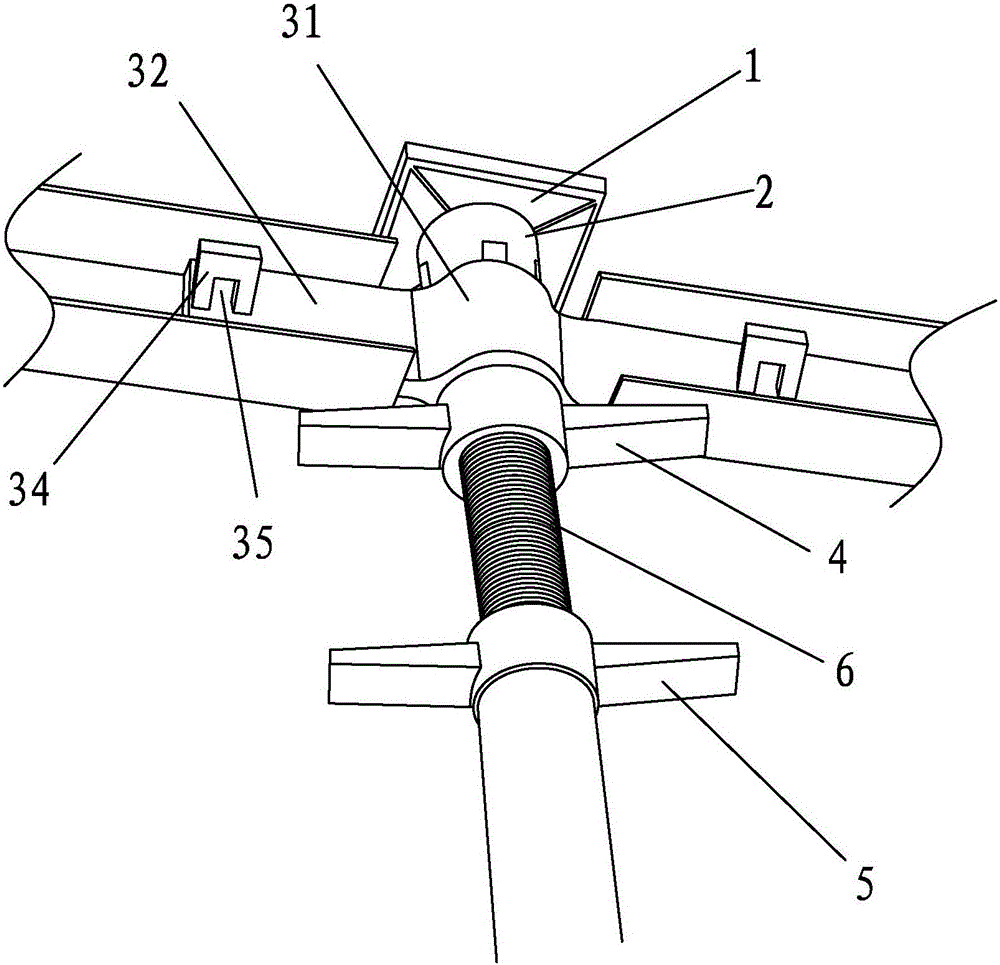

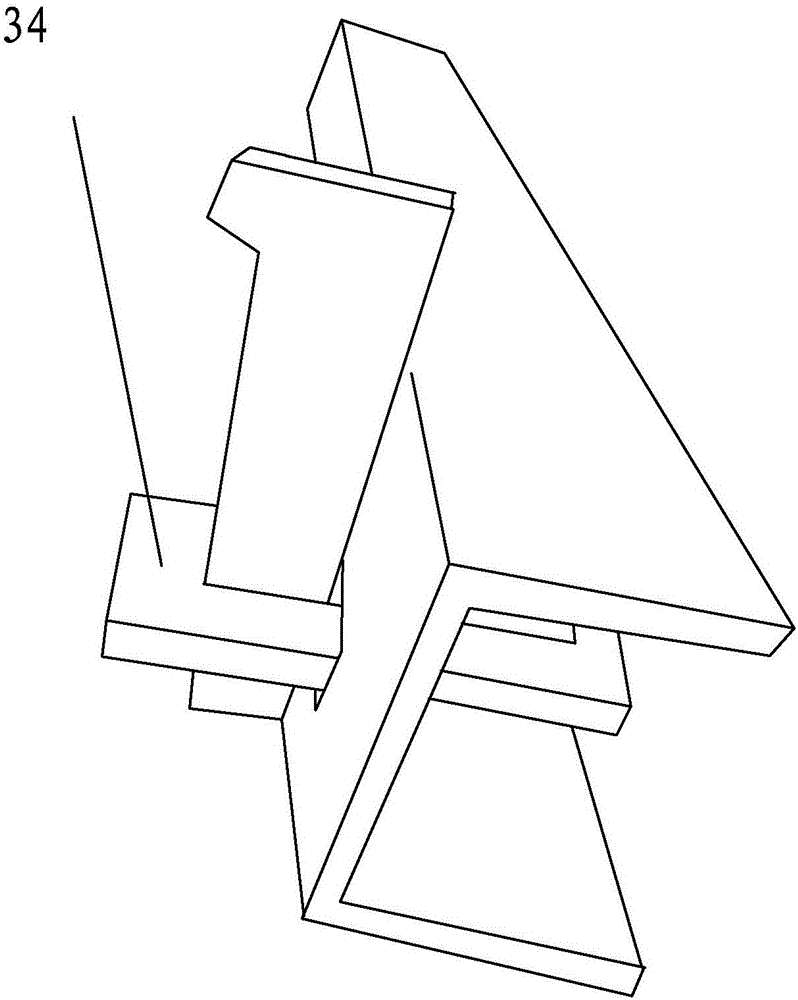

[0030] Such as Figure 1-4 As shown, an early demolition jack for building formwork support has a support plate 1, a support 2, an early demolition support 3, an adjustment device and a support column. Preferably, the adjustment device includes an adjustment nut 4 and an adjustment nut 5 , and the support column is a screw rod 6 .

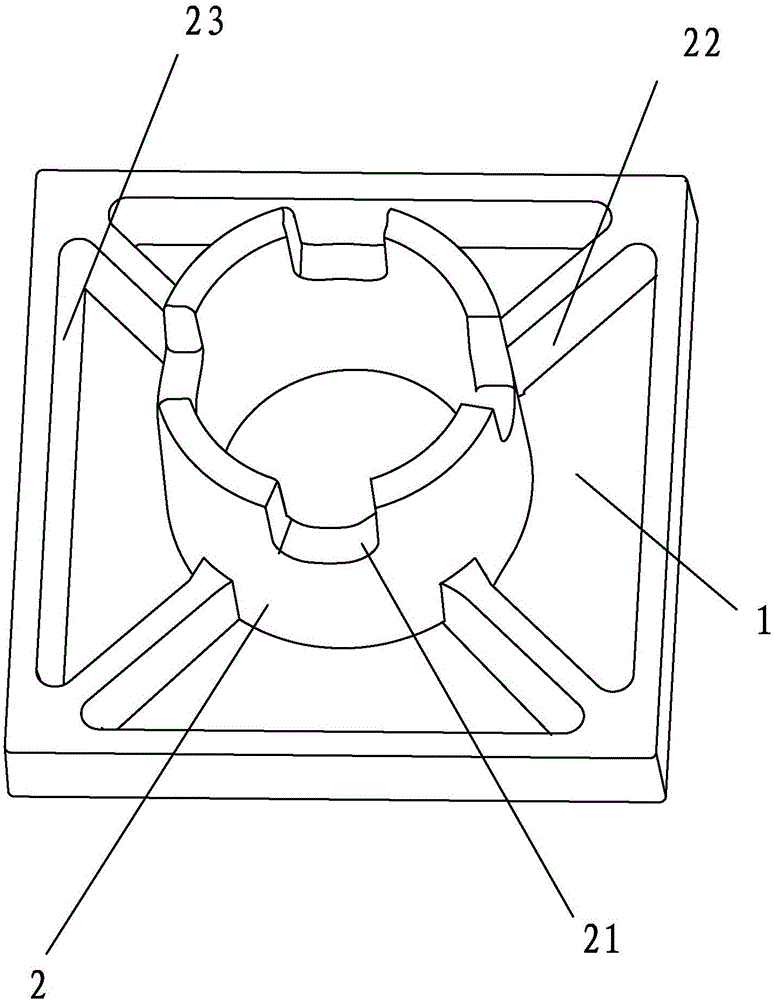

[0031] The supporting board 1 is arranged on the supporting bracket 2, and the supporting board 1 has a forming surface and a connecting surface. The molding surface is in the shape of a horizontal plane. The supporting bracket 2 is cylindrical and annular, and the upper end of the supporting bracket 2 is connected to the center of the connecting surface of the supporting plate 1 . There are four notches 21 along the lower end of the support 2, and the notches 21 are evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com