Auxiliary charging device for on-site mixed emulsified explosive charging vehicle

An emulsion explosive, on-site mixing technology, applied in blasting and other directions, can solve the problems of discontinuous charge in blasting holes, stuck holes in blasting holes, uneven working surface of blasting area, etc., so as to protect blasting hole wall and reduce labor intensity. , The effect of on-site loading is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

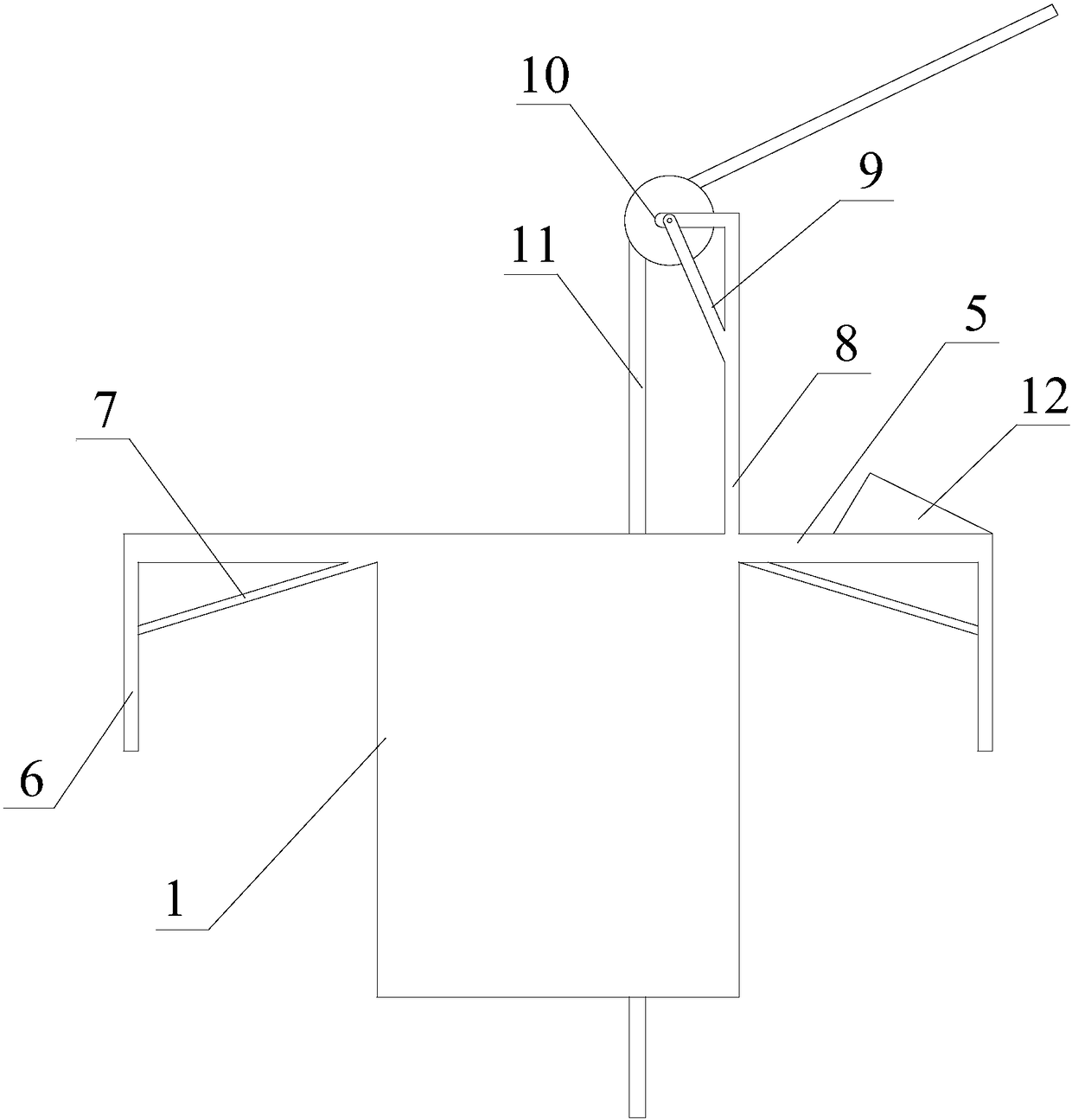

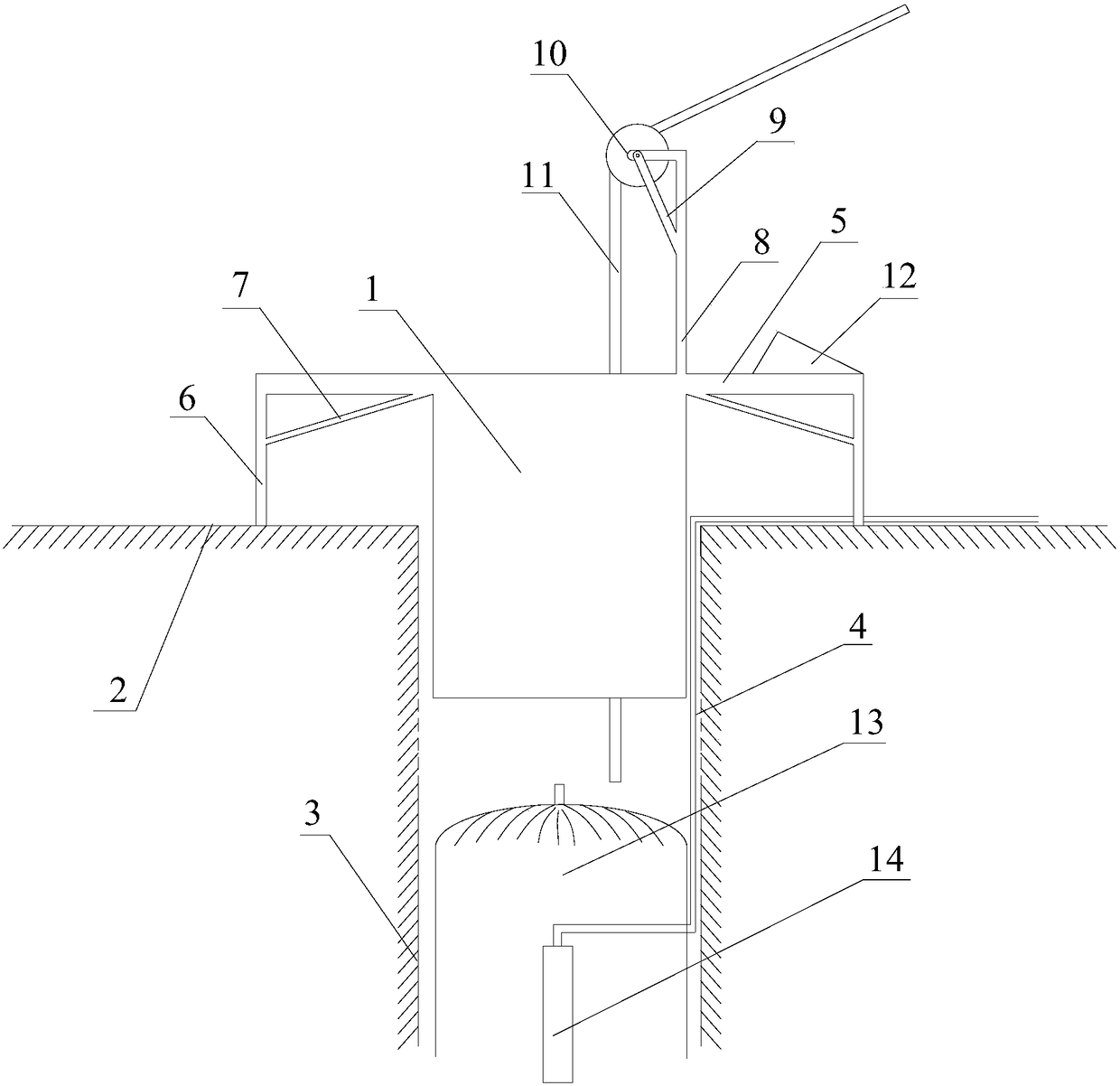

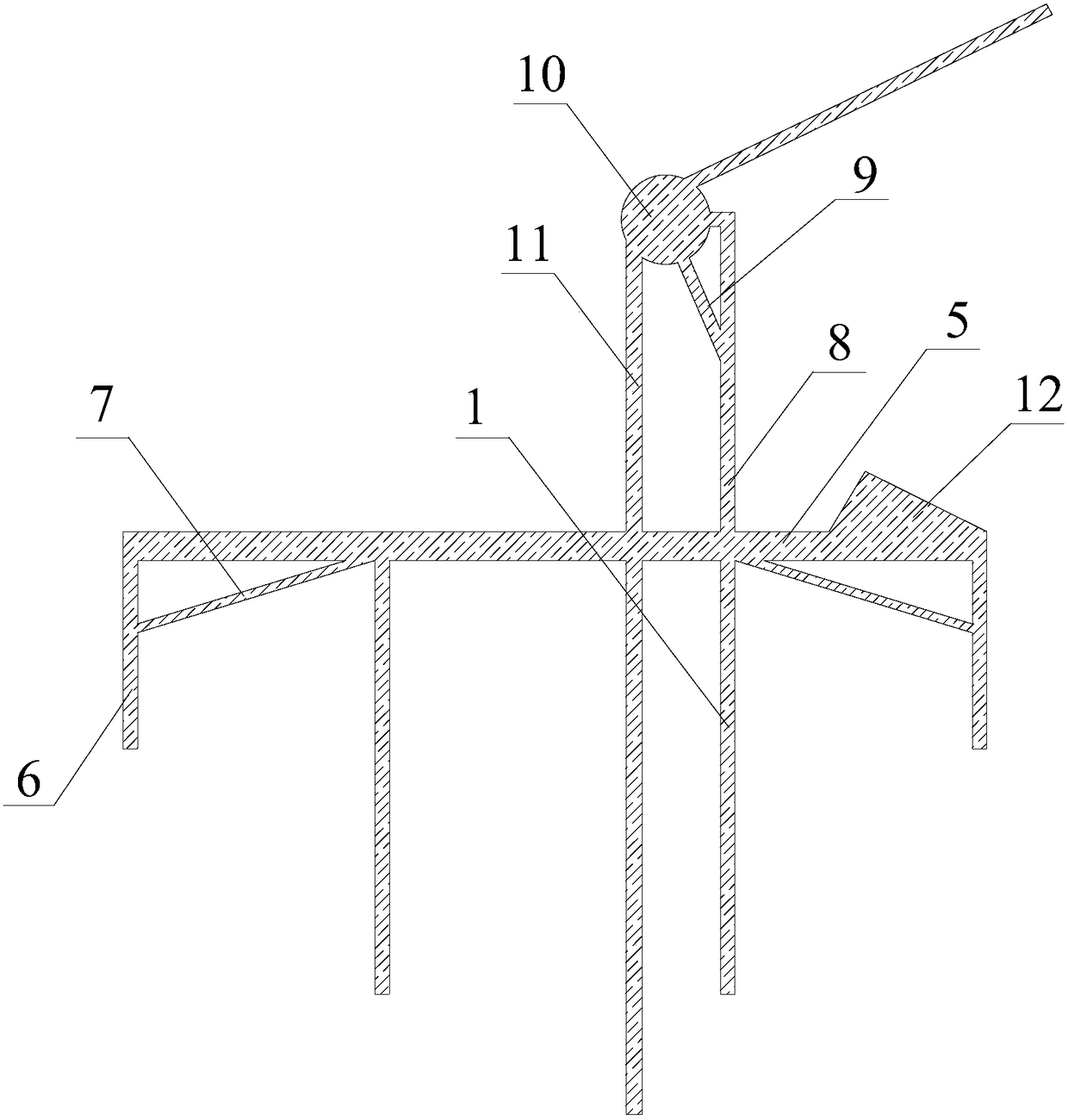

[0033] Such as Figure 1 ~ Figure 3 As shown, the auxiliary charging device of the on-site mixed emulsified explosive charging vehicle of this embodiment includes the auxiliary charging device body 1, a support and a lifting mechanism;

[0034]The auxiliary charging device body 1 is used to protect the wall 3 of the blast hole, and includes a metal ring and an antistatic rubber layer wrapped around the metal ring. By designing the metal ring and the antistatic rubber layer of the auxiliary charging device body 1, It can well play the role of anti-static, and prevent the electric detonator from being accidentally caused by the interference of static electricity.

[0035] In this embodiment, the laying of the metal ring of the auxiliary charging device body 1 is in the shape of a mesh, and the material of the metal ring is steel, and the mesh-shaped metal ring is wrapped with an antistatic rubber layer, which can not only save the auxiliary charging device The material cost is ...

Embodiment 2

[0046] The main features of this embodiment are: as Figure 5 As shown, the main body 1 of the auxiliary charging device is hollow cylindrical, and there are three supports, and setting three supports can ensure the stability of the main body 1 of the auxiliary charging device and save materials; On the circumference of the device body 1, the angle between two adjacent supports is 360 / 3=120 degrees. All the other are with embodiment 1.

Embodiment 3

[0048] The main features of this embodiment are: the laying of the eyelets of the auxiliary charging device body 1 is in a mesh shape, and the material of the eyelets is iron. All the other are with embodiment 1 or 2.

[0049] In summary, the body of the auxiliary charging device of the present invention includes a metal ring and an antistatic rubber layer wrapped around the metal ring. By designing the metal ring and the antistatic rubber layer of the auxiliary charging device body, it can be well played. The anti-static function prevents accidental occurrence of the electric detonator due to the interference of static electricity, etc., and through the design of the auxiliary charge device body, it can well protect the wall of the blast hole and prevent pumice on the working surface. Falling into the blast hole, the resulting blast hole jams and affects the charge; the support is arranged around the body of the auxiliary charge device, and is respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com