Fiber Bragg Grating Sensing System and Method for Simultaneous Measurement of Temperature and Strain

A fiber grating and sensing system technology, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and converting sensor outputs, etc. problem, to achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

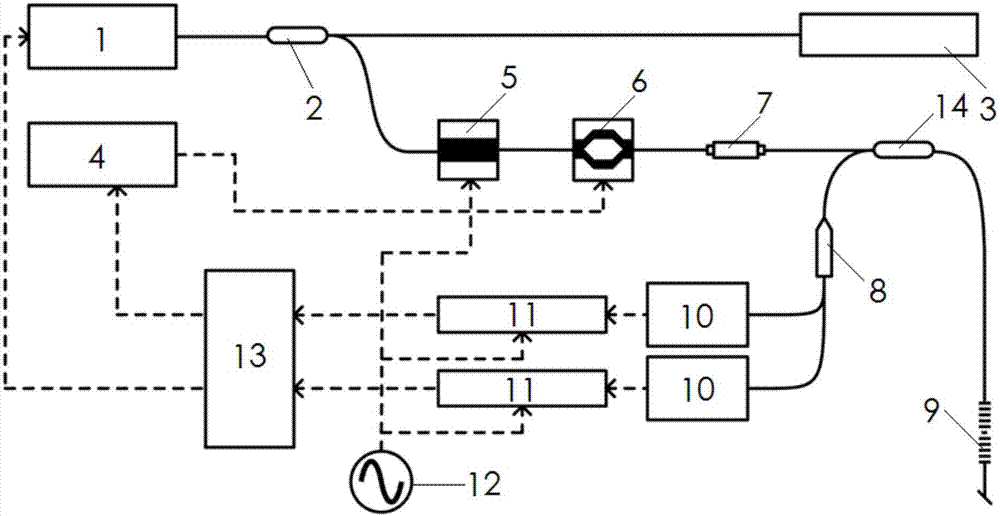

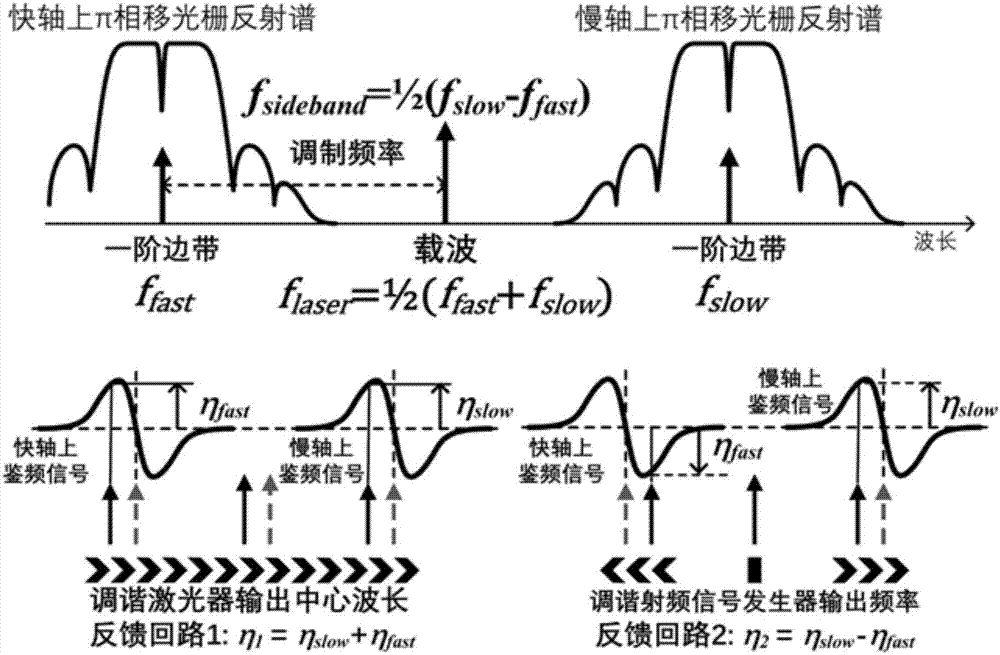

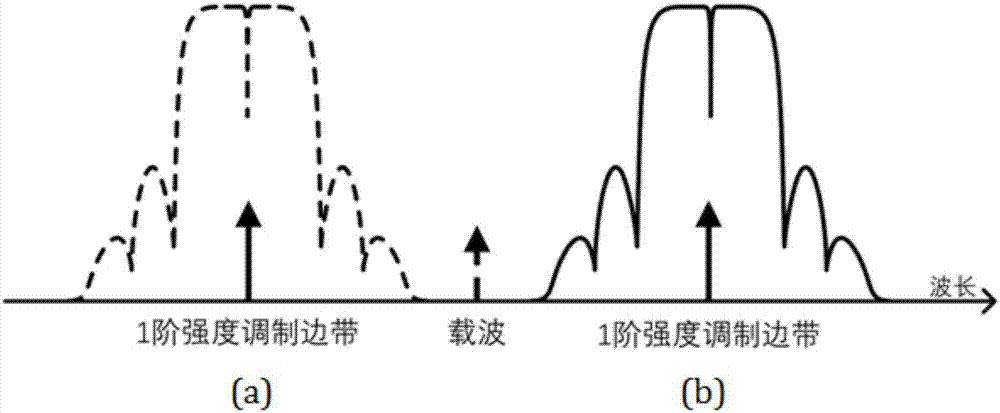

[0038] Such as figure 1 As shown, this embodiment includes: a detection light branch, a feedback detection branch, a polarization-maintaining optical coupler 14, a modulation unit and a calculation unit, wherein: the detection light output by the detection light branch with double-sided band intensity modulation passes through the input sensor grating 9. Detect the center of the transmission peak on the fast axis and slow axis of the sensing grating 9, and the reflection signal of the sensing grating 9 is input to the feedback detection branch through the polarization maintaining optical coupler 14; the modulation unit is based on the control instructions and readings of the calculation unit , output the frequency signal to the detection light branch, the calculation unit collects and feeds back the data of the detection branch to correct the frequency parameters of the modulation unit, forming two closed-loop feedback loops, and locks the two sidebands of the detection light o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com