A wedge-shaped microhole fiber grating capable of simultaneously measuring seawater temperature, salinity and pressure

A technology of micro-hole optical fiber and salinity, which is applied in the direction of cladding optical fiber, grating fiber, measuring device, etc., can solve the problems of packaging and practical application difficulties, and achieve the effect of solving cross-sensitivity problems and eliminating the influence of salinity and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

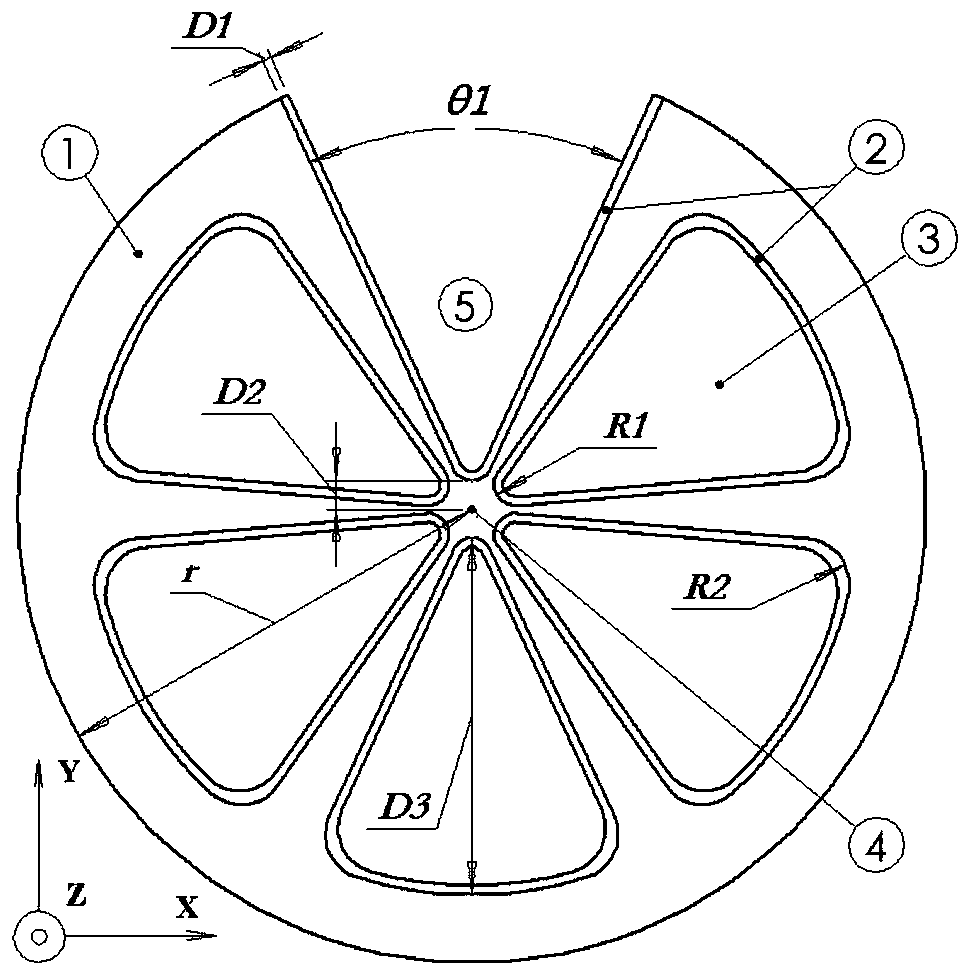

[0026] The invention proposes a wedge-shaped microhole fiber grating integrated structure capable of producing a high birefringence effect. like figure 1 Shown is a cross-sectional view of a wedge-shaped microhole fiber grating. Firstly, the microhole optical fiber was prepared by the stack-drawing technique (n 0 =1.45), and its outer diameter r=62.5 μm. A wedge-shaped defect is introduced by micro-processing technology to form an asymmetric birefringent structure, and the wedge angle θ1=50°. In this structure, a metal film is introduced at the microporous surface and at the defects: D1 = 30 nm. Microwells filled with PDMS(n PDMS =1.42) has a high negative thermo-optic coefficient, which improves the temperature-sensitive and mechanical properties of the structure. The relevant dimensions for micropores and wedge-shaped defects are: D2 = 5 μm, R1 = 6 μm, D3 = 45 μm, R2 = 10 μm.

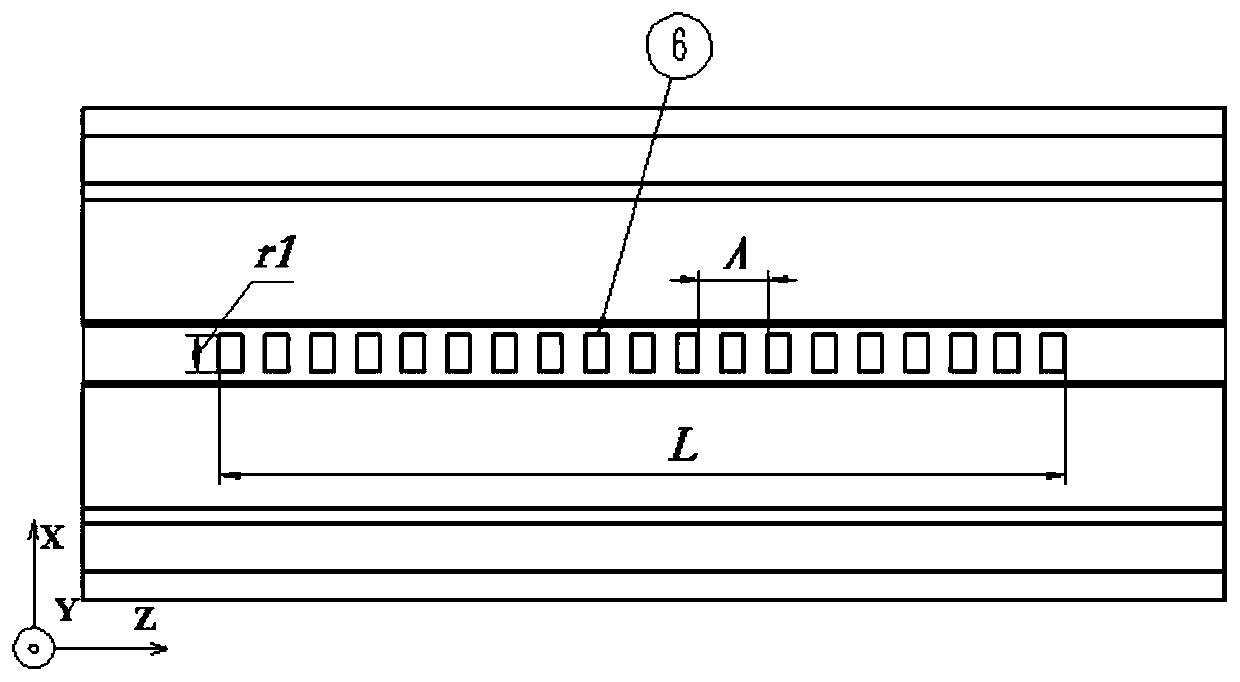

[0027] exist figure 2 A radial view of a microhole fiber grating is given in . A refracti...

Embodiment 2

[0041] The invention proposes a wedge-shaped microhole fiber grating integrated structure capable of producing a high birefringence effect. like figure 1 Shown is a cross-sectional view of a wedge-shaped microhole fiber grating. Firstly, the microhole optical fiber was prepared by the stack-drawing technique (n 0 =1.45), and its outer diameter r=62.5 μm. A wedge-shaped defect is introduced by micro-processing technology to form an asymmetric birefringent structure, and the wedge angle θ1=55°. In this structure, a metal film is introduced at the microporous surface and at the defects: D1 = 20 nm. Microwells filled with PDMS(n PDMS =1.42) has a high negative thermo-optic coefficient, which improves the temperature-sensitive and mechanical properties of the structure. The relevant dimensions for micropores and wedge-shaped defects are: D2 = 3 μm, R1 = 6 μm, D3 = 35 μm, R2 = 10 μm.

[0042] exist figure 2 A radial view of a microhole fiber grating is given in . A refracti...

Embodiment 3

[0050] The invention proposes a wedge-shaped microhole fiber grating integrated structure capable of producing a high birefringence effect. like figure 1 Shown is a cross-sectional view of a wedge-shaped microhole fiber grating. Firstly, the microhole optical fiber was prepared by the stack-drawing technique (n 0 =1.45), and its outer diameter r=62.5 μm. A wedge-shaped defect is introduced by micro-processing technology to form an asymmetric birefringent structure, and the wedge angle θ1=45°. In this structure, a metal film is introduced at the microporous surface and at the defects: D1 = 40 nm. Microwells filled with PDMS(n PDMS = 1.42). The relevant dimensions for micropores and wedge-shaped defects are: D2 = 7 μm, R1 = 6 μm, D3 = 55 μm, R2 = 10 μm.

[0051] exist figure 2 A radial view of a microhole fiber grating is given in . A refractive index modulated fiber grating structure is introduced at the waveguide core by ultraviolet exposure or femtosecond laser proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com