Detection method for quality of electric power pipe gallery reinforcing steel bar mesh based on machine vision and detection device

A quality inspection method and technology for power pipe gallery, applied in the direction of instruments, data processing applications, calculations, etc., can solve problems such as not setting tie bars according to regulations, collapse of teaching buildings, unsatisfactory test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

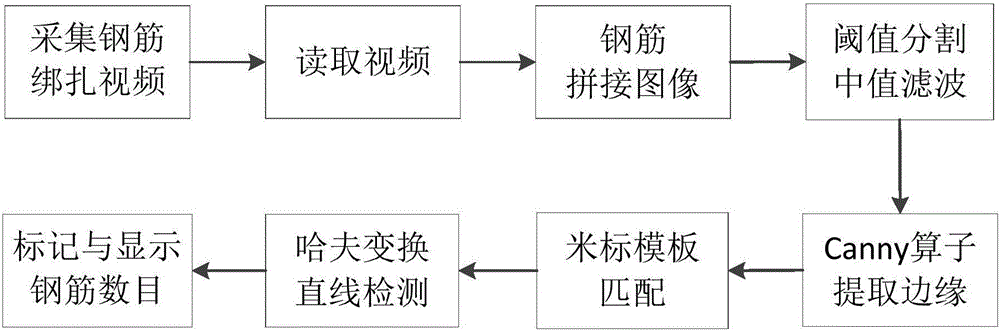

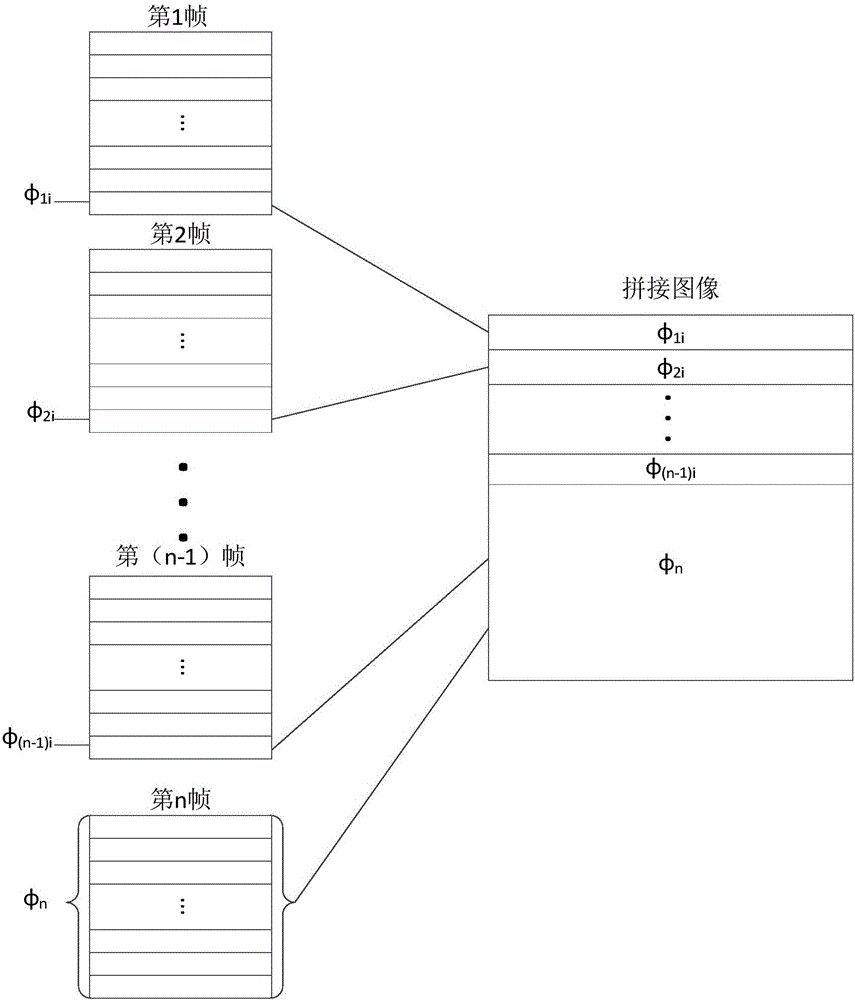

[0063] The invention utilizes self-developed data acquisition equipment to collect video of steel bar binding at the construction site, and realizes standard detection of steel bar quantity, spacing and diameter and construction standard judgment through a monitoring software platform. The invention is divided into four modules: self-developed video acquisition equipment, steel bar quantity detection and judgment, steel bar spacing detection and judgment, steel bar diameter detection and judgment.

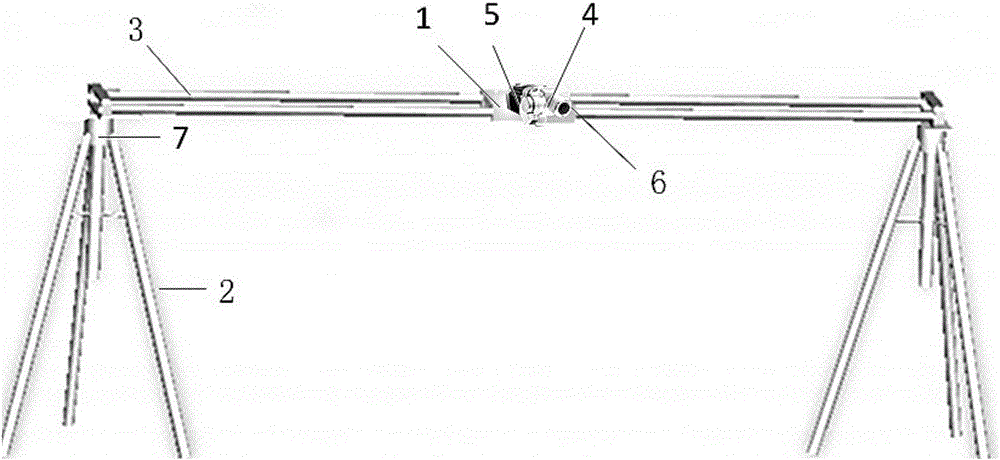

[0064] The video acquisition equipment module independently developed by the present invention includes two telescopic triangular supports 2 , a double-tube guide rail 3 , a stepping motor 5 and a camera 6 . After the steel bar binding on a certain floor of the power pipe gallery is completed, and after entering the inspection stage, the video collection of the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com