Operating mechanism for three-position closing band holding device

A technology of holding device and operating mechanism, which is applied to the contact drive mechanism and other directions, can solve the problems of poor safety design of the operating mechanism, etc., and achieve the effects of convenient spring adjustment, good safety, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

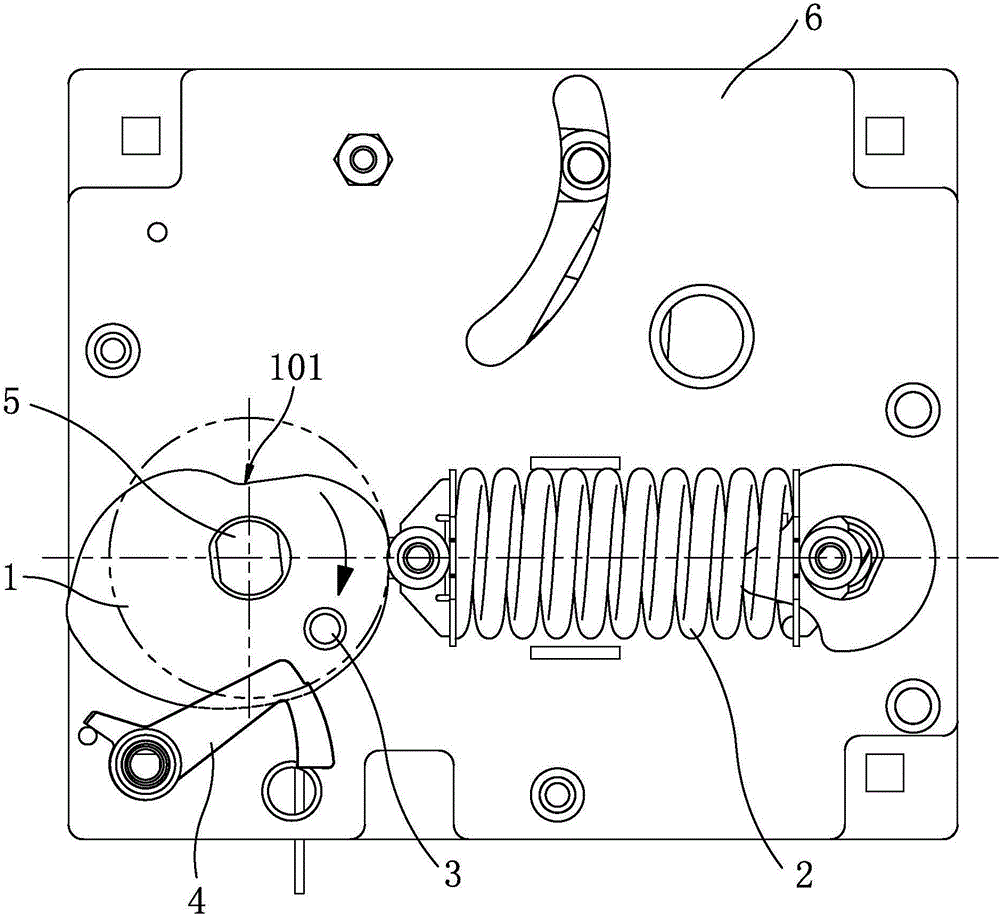

[0014] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as figure 1 as shown, figure 1 It is the state when the mechanism is close to the closing position. When the roller on the eccentric wheel rotates clockwise and contacts the detent surface, the closing is completed. One side of the side plate 6 of the operating mechanism is provided with an eccentric wheel 1, a spring 2 and a detent 4, and the side plate at the spring is symmetrically provided with limit ribs, and the spring is arranged in the spring groove between the limit ribs; Spring seat is provided with spring roller respectively, and the spring roller of two ends spring seat is arranged on the slide hole of side plate by spring shaft; Eccentric wheel is connected with an end of main shaft 5, and the axle center of main shaft and spring roller is on the same straight line. The outer wheel surface of the eccentric wheel is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com