A high-voltage DC circuit breaker valve tower structure

A high-voltage direct current and circuit breaker technology, applied in the field of high-voltage direct current circuit breaker valve tower structure, can solve problems such as the lack of mature products, and achieve the effects of improving seismic performance, small horizontal footprint, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

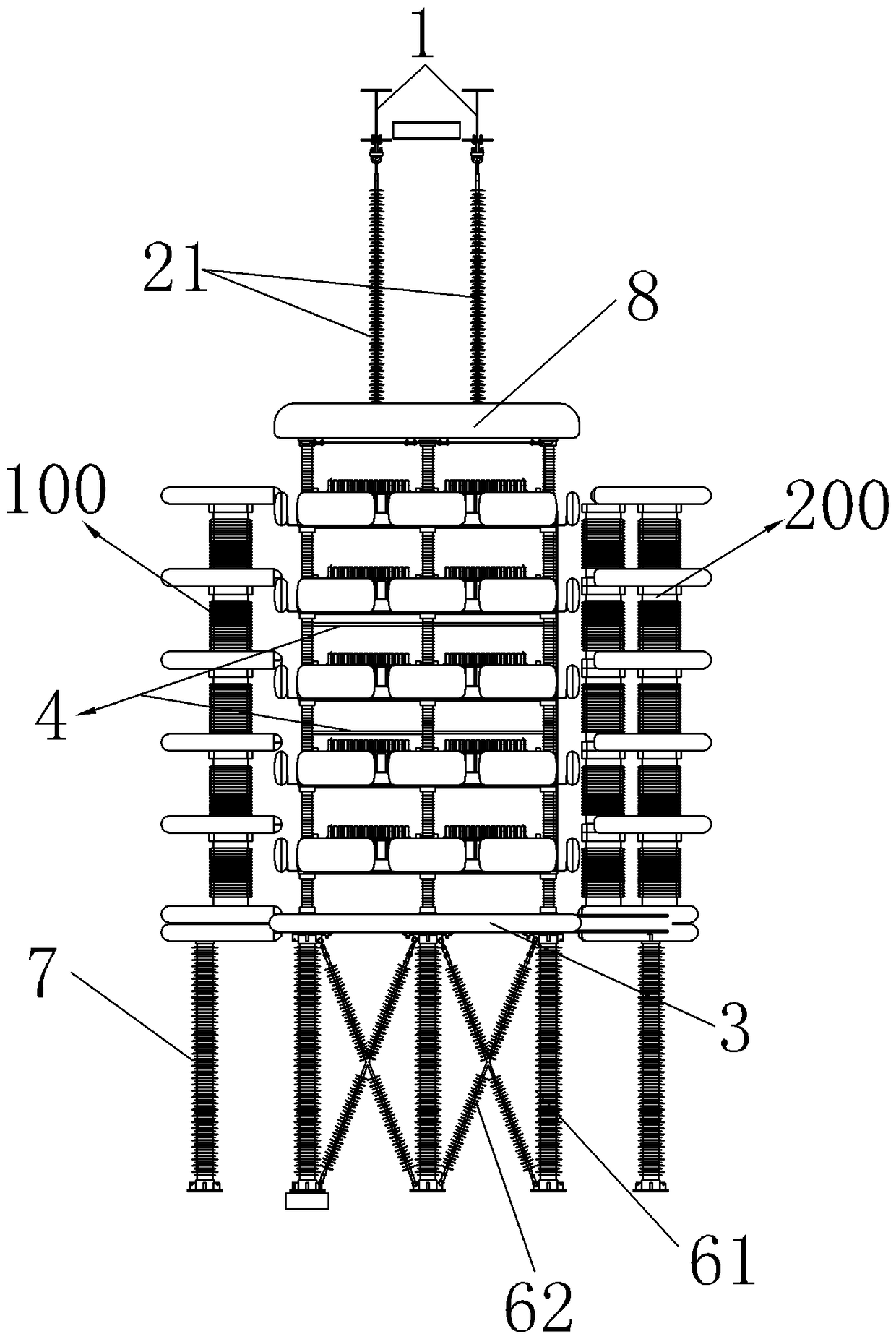

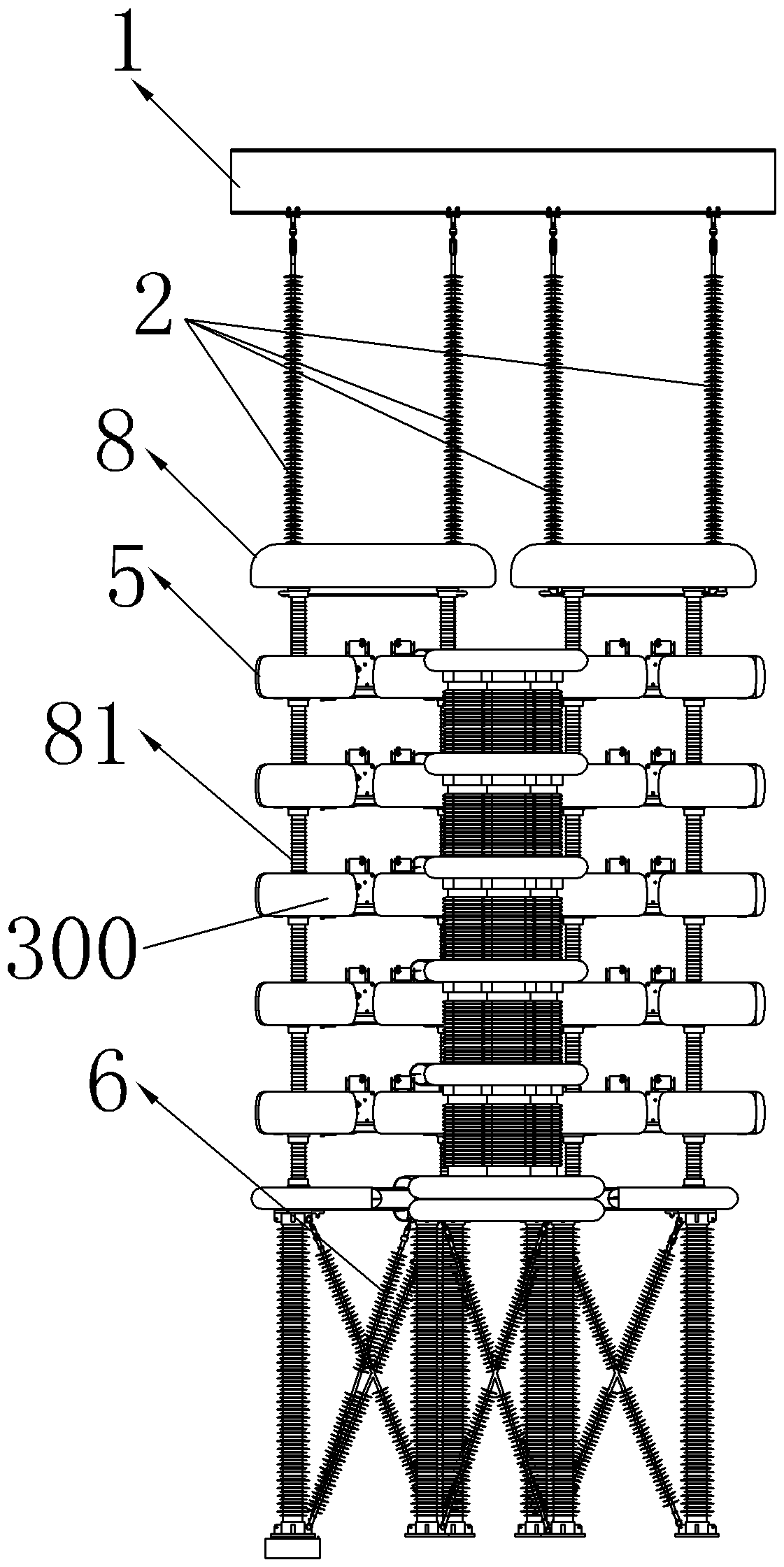

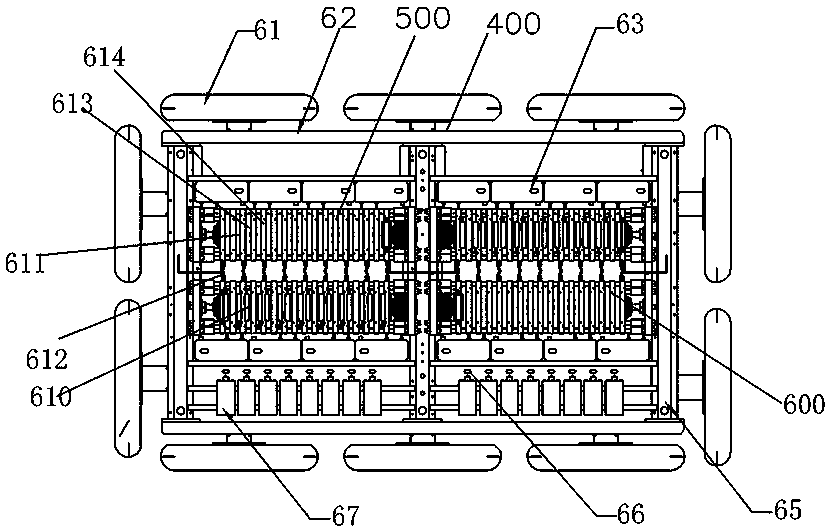

[0026] A specific embodiment of the valve tower structure of a high-voltage DC circuit breaker of the present invention, as Figure 1 to Figure 5 As shown, the valve tower structure in this embodiment includes a plurality of circuit breaker power assemblies 5 for sequential series connection, the plurality of circuit breaker power assemblies 5 are arranged in layers at intervals along the upper and lower directions, and any adjacent two-layer circuit breaker power assemblies The interlayer support structure is fixedly installed between them to form the valve tower main body 300. The interlayer support structure here specifically adopts the interlayer support insulator 81, and each valve tower main body has 5 layers of circuit breaker power components 5 respectively. In this embodiment, the valve tower bodies 300 here are arranged in two rows at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com