Efficient dehydrating chamber type filter press

A box-type filter press, high-efficiency technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as poor dehydration effect, easy deformation of filter plates, and blockage of filter cloth meshes, so as to reduce labor costs and maintenance costs, good extrusion dehydration, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

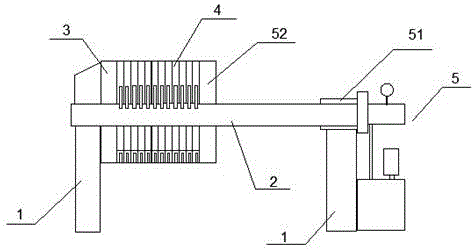

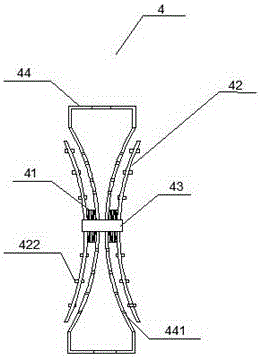

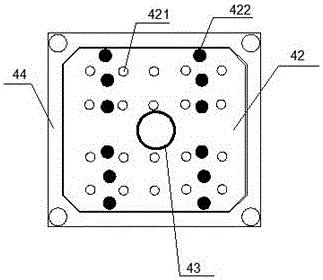

[0016] As shown in the figure, the high-efficiency dewatering chamber filter press of the present invention has a bracket 1, a beam 2, a thrust plate 3, a pressing device 5 and a filter device. The left and right ends of the beam 2 are arranged at the On the support 1, the thrust plate 3 is fixed at one end of the beam 2, the pressing device 5 is provided at the other end of the beam 2, and the filter device is provided at the thrust plate 2 and In the middle of the pressing device 3, the filter device includes a plurality of filter units 4 arranged in parallel. The filter unit 4 includes a spring 41, a pressing plate 42, a feed rod 43, a filter plate 44 and a filter plate arranged on the filter plate. The filter cloth 44 is provided with recesses 441 in the middle of the left and right side walls of the filter plate 44, the feed rod 43 is hollow, and the filter plate 44 is sleeved on the feed rod 43 and is located on the feed rod In the middle of 43, the two ends of the feed r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap