Steel plate strip leveling machine

A technology of leveling machine and slats, which is applied in the field of special equipment for steel plate blanking, can solve the problems that parts are easy to leave hammer marks, affect the surface quality of products, and increase the rate of customer complaints, and achieve reliable product quality, simple structure, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

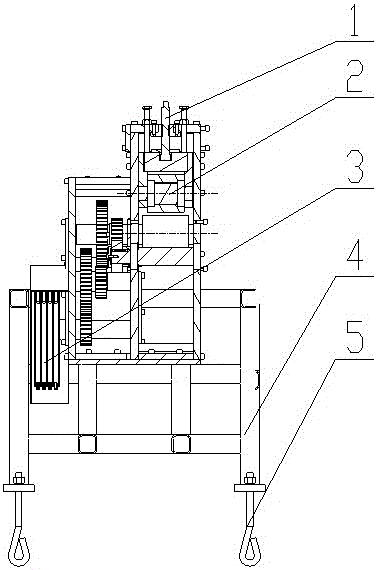

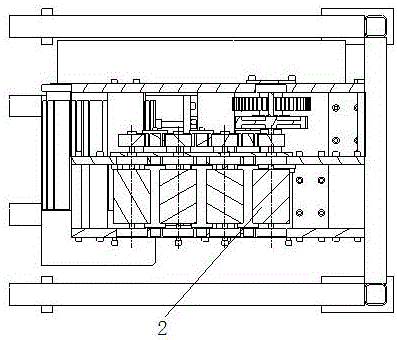

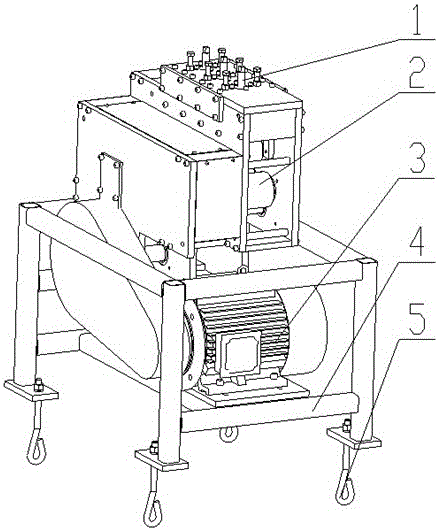

[0017] Such as figure 1 , figure 2 with image 3 As shown, the four corners below the frame 4 are provided with connector anchor bolts 5 for machine installation. The drive motor of the transmission system 3 is arranged inside the frame 4, and the output end of the drive motor is provided with a pulley. A transmission box and a roller set 2 are arranged on the top of the frame 4. There is a gear set in the transmission box. The input end of the roll set 2 is connected to the gear set. The output of the drive motor passes through the belt pulley to the gear set. After the speed is changed, the drive roller set 2 rotates. There is an adjustment mechanism 1 above the box where the roller group 2 is installed. The adjustment mechanism 1 adopts a manual adjustment method. The screw can drive the upper roller group to move up and down, and the lower roller group is set as a fixed structure, so that the gap between the two roller groups can be adjusted. The purpose is to be suita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com