Stamping process and automatic stamping equipment for the main body of the switchgear chassis

A thin plate stamping and chassis car technology, which is applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of safety hazards, hand cuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

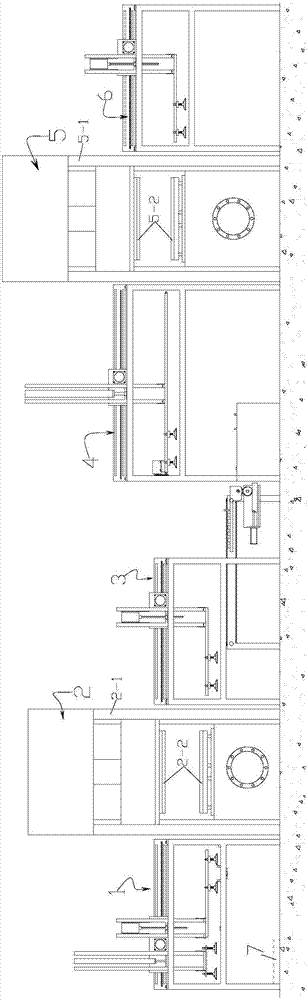

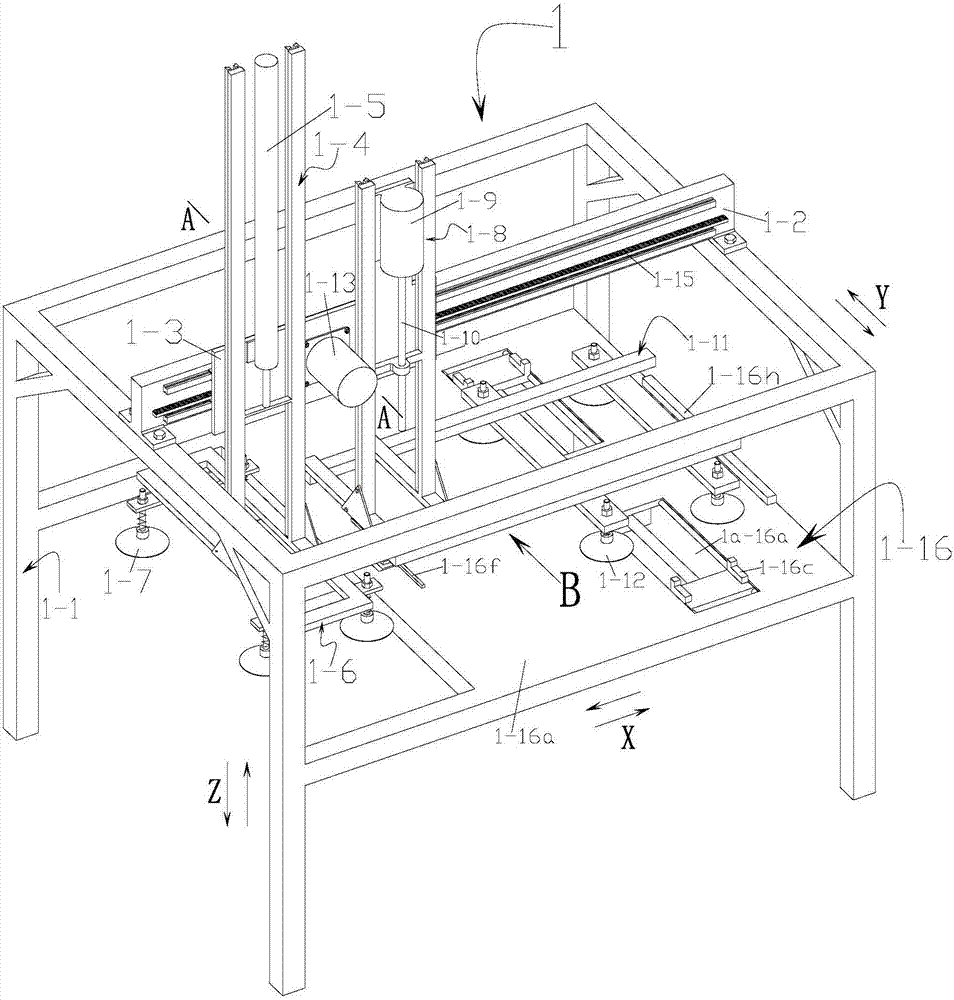

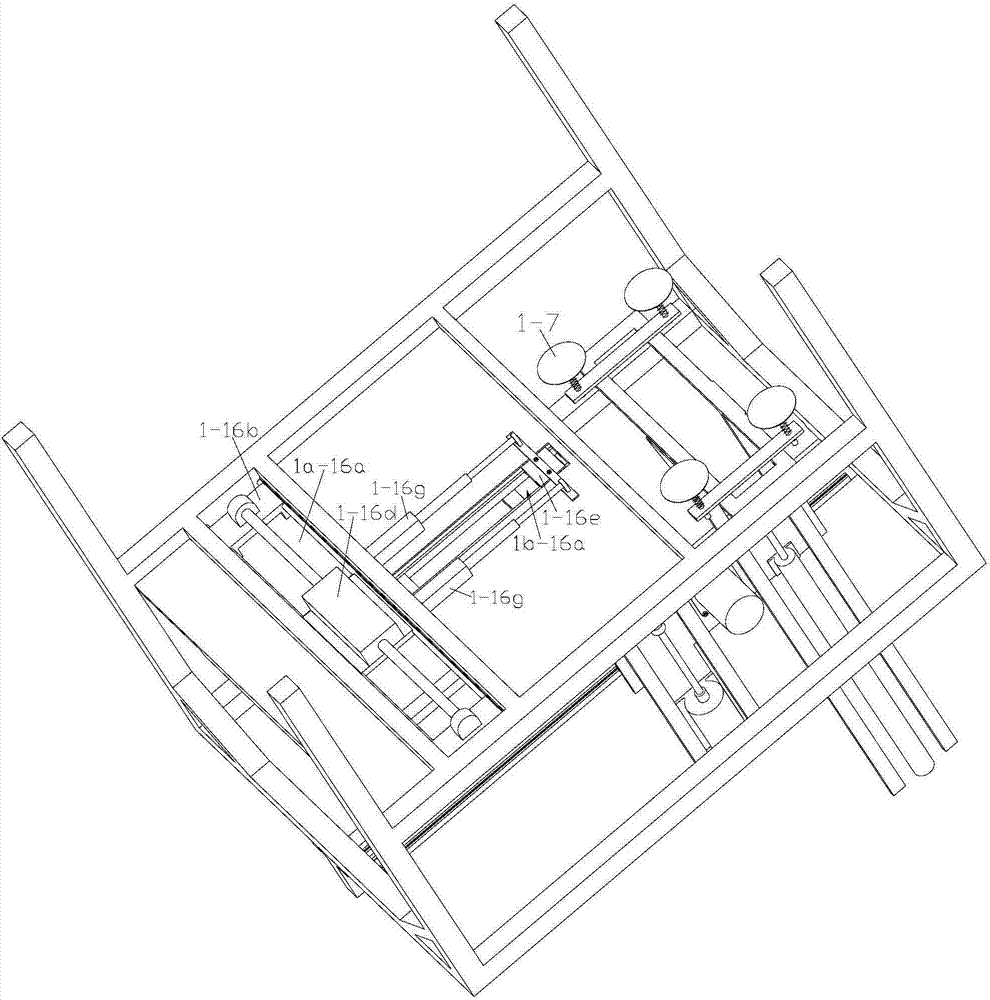

[0045] Refer to attached figure 1 , 2 , 4, 5, 6, 7, 8, 9, 10, 11, 13, 14, 15, 16, 17, 18, 19, 20, 21:

[0046] A stamping process for a main body of a switchgear chassis, comprising the following steps:

[0047] A. Feeding: Place the thin plate raw material 8 on the raw material placement table 7, start the first cylinder 1-5 to drive the square horizontal frame 1-6 to move down, until the vacuum suction cup 1-7 sucks the thin plate raw material 8, the first cylinder 1 -5 drives the thin plate raw material 8 to move up to the initial position of the square horizontal frame 1-6, and then the servo motor two 1-13 drives the moving plate one 1-3 to move to the right, and brings the thin plate raw material 8 to the correction mechanism one 1-16 Above, then the first cylinder 1-15 drives the square horizontal frame 1-6 to move down for a short distance, the vacuum suction cup 1-7 inflates to place the sheet material 8 on the support plate 1-16a, and starts the first multi-stage c...

Embodiment 2

[0062] Refer to attached Figure 12 : This switchgear chassis car main body thin plate automatic stamping equipment is different from embodiment one in that: drive mechanism 3-21 includes servo motor nine 3-21c and reversing reducer 3-21 fixed on the support frame 3-19 21d, the rotating shaft of servo motor nine 3-21c is fixed on the input shaft place of reversing reducer 3-21d, and the output shaft of reversing reducer 3-21d is fixed with gear six 3-21e, gear six 3-21e and gear four 3-18 gear meshing. The principle of its stamping thin plate raw material 8 is the same as that of Embodiment 1, except that the power source of the drive mechanism 3-21 utilizes servo motor 9 3-21c, reversing reducer 3-21d and gear 6 3-21e to drive gear 4 3-18 Rotate and drive the rotating rod 3-14 to rotate 180° clockwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com