Process method and system for continuous casting circulating cooling water and slab waste heat utilization

A circulating cooling water and cooling water treatment technology, which is applied in the field of slab cooling water and slab radiant heat utilization, can solve problems such as waste of heat energy, and achieve the effect of increasing economic benefits and reducing input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

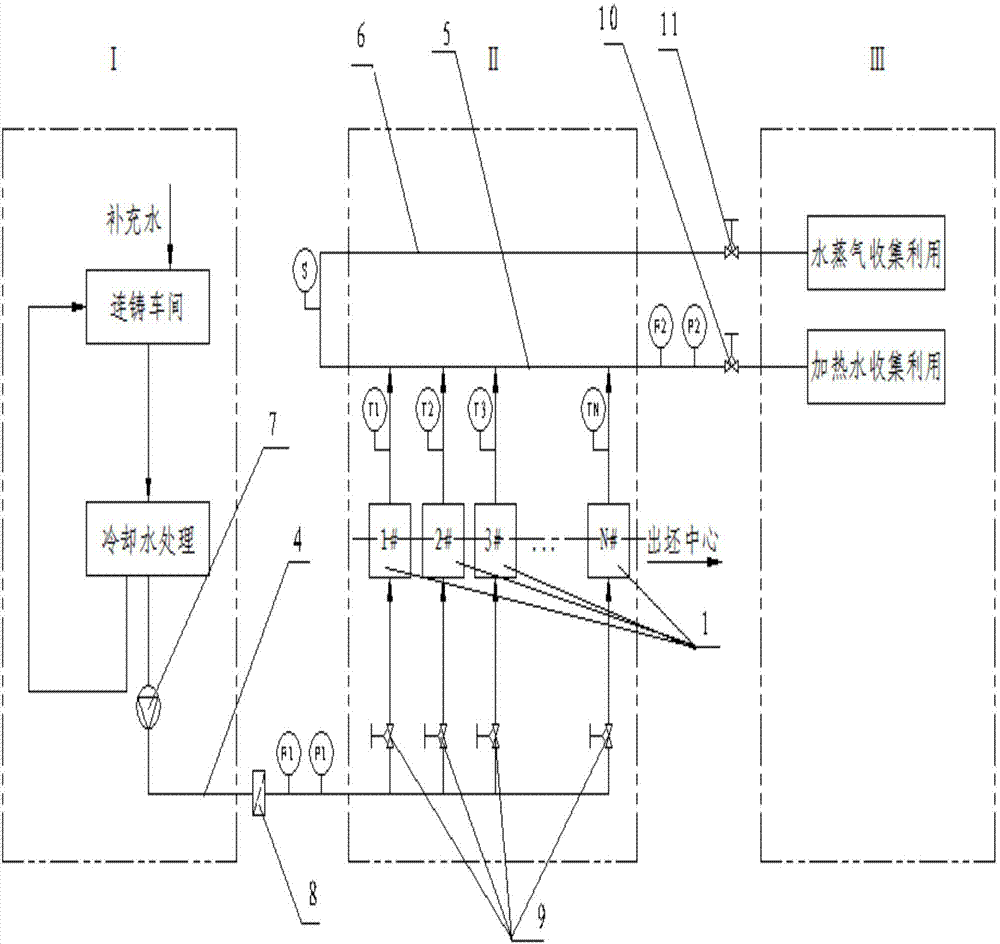

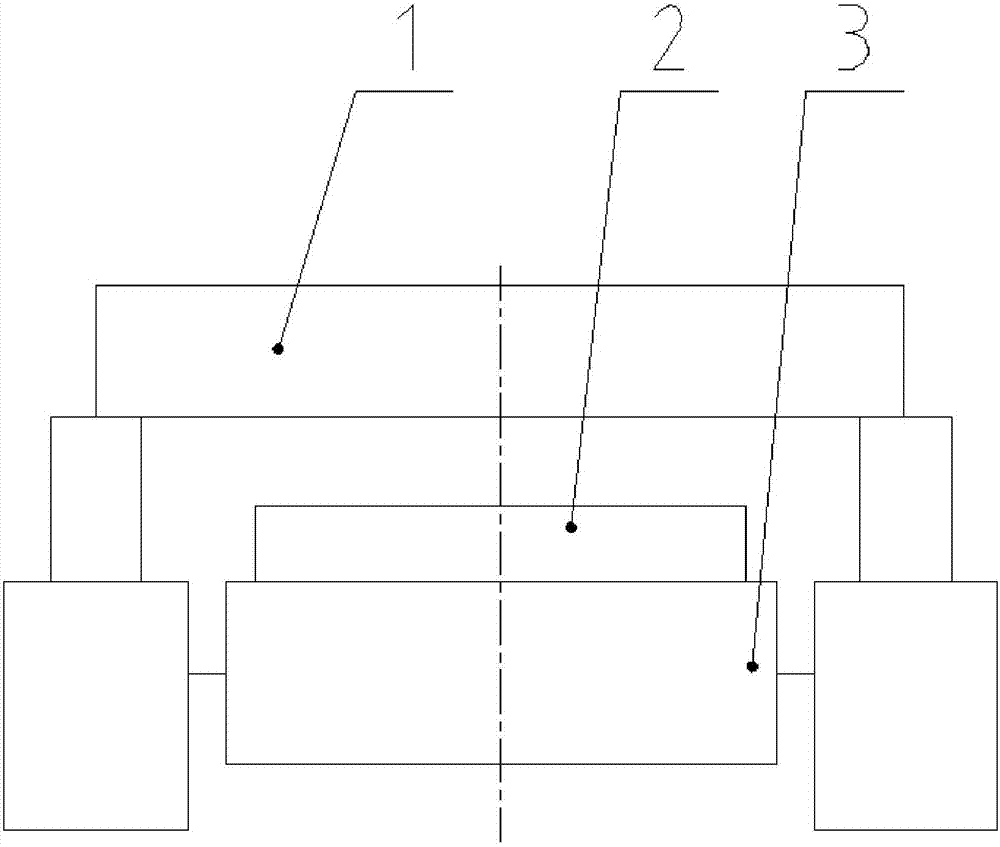

[0019] Continuous casting circulating cooling water and slab waste heat utilization system, including cooling water device part Ⅰ, slab waste heat baking and heating device part Ⅱ and collection device part Ⅲ, cooling water device part Ⅰ includes continuous casting workshop cooling water treatment device, water pump group 7 and The cold water pipeline 4 is provided with a water outlet on the cooling water treatment device of the continuous casting workshop. One end of the road 4 is connected, and the cold water pipeline 4 is provided with a filter 8 and a cold water flowmeter F in sequence. 1 and cold water pressure gauge P 1 ; Part II of the slab waste heat baking heating device includes a slab roller table, a heat exchanger 1, a liquid separator S, a hot water pipeline 5 and a steam pipeline 6, and the heat exchanger 1 is arranged above the slab roller table, The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com