A kind of low-pressure casting machine and pouring method thereof

A technology of low pressure casting machine and pouring method, applied in the field of low pressure and differential pressure manufacturing, can solve the problems of low casting quality, low production efficiency, poor product manufacturing precision, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

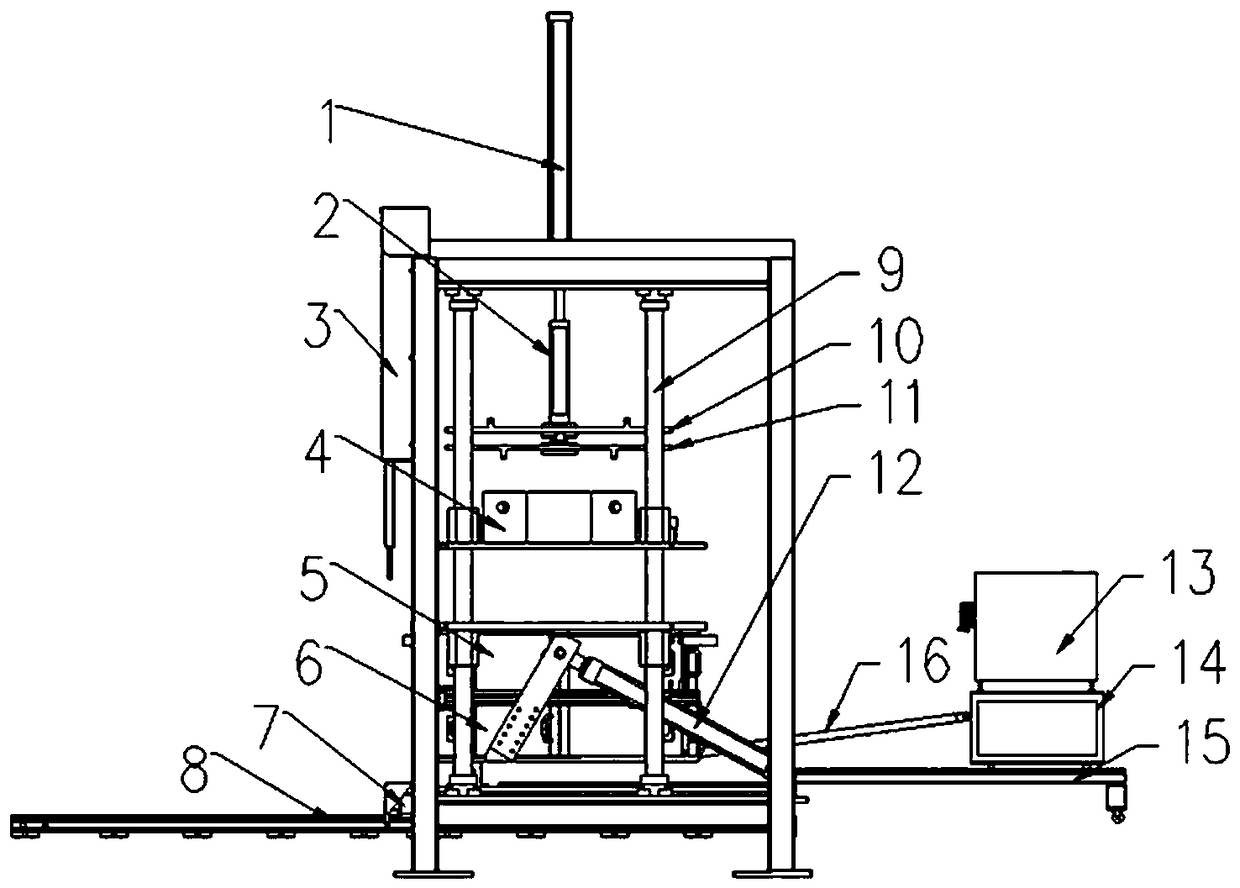

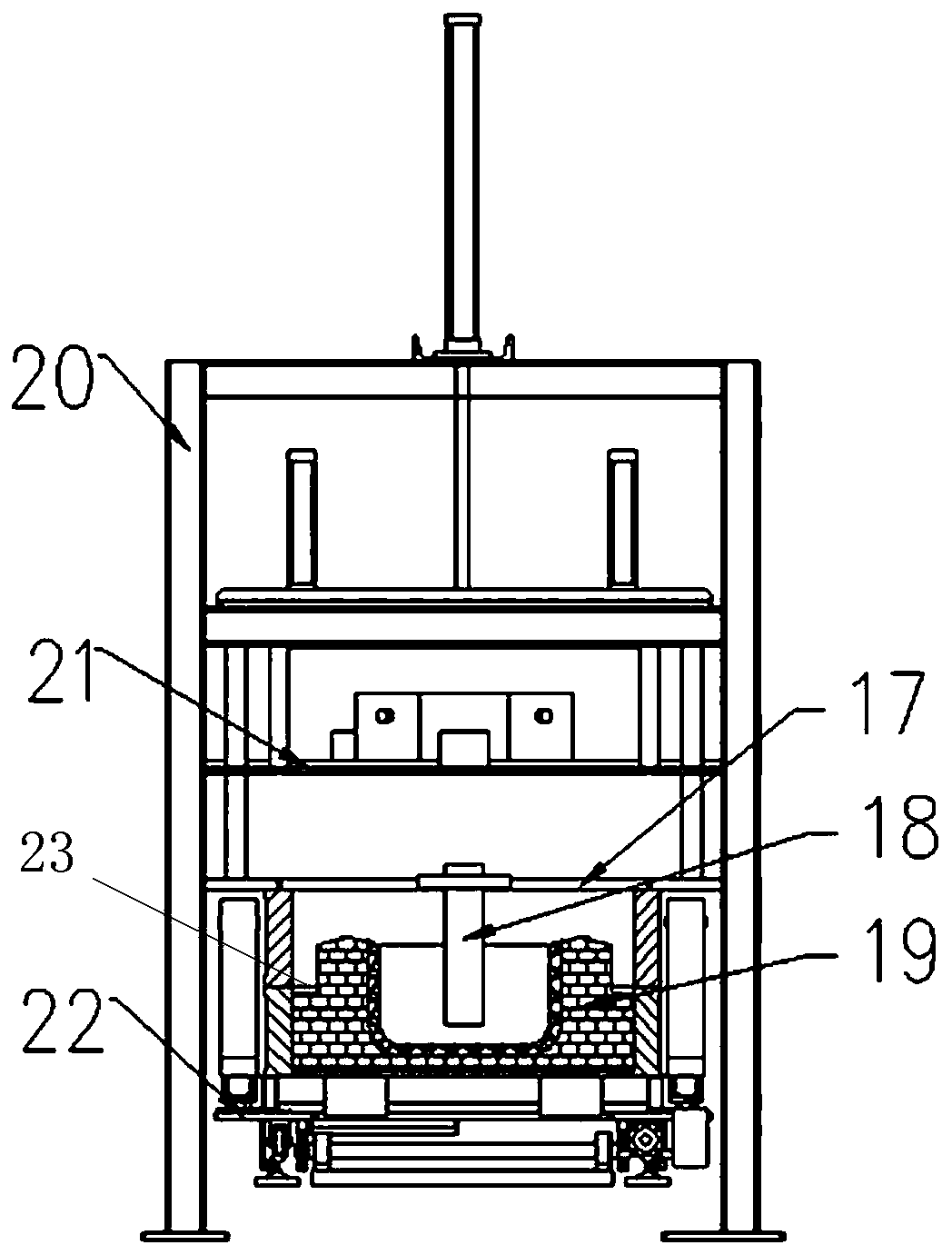

[0027]The low-pressure casting machine includes a frame, a holding furnace installed in the frame, and a host that cooperates with the holding furnace. The host includes a furnace body platform, guide rails, a power follower mechanism, a molten steel level measurement mechanism, a sand box platform, Furnace cover platform, hydraulic cylinder fixing plate, hydraulic cylinder connecting plate and four-column guiding mechanism. The holding furnace includes a furnace body and a furnace cover, a tilting arm is fixed on the side wall of the furnace body, and the tilting arm is connected to a hydraulic cylinder D; the automatic control system includes a liquid level pressurization control system and a hydraulic cylinder automatic control; the guide rails are arranged horizontally and are divided into two tracks on the left and right; the bottom of the furnace body platform is provided with rollers, the upper part is fixed to the furnace body, and the side wall is provided with a hydra...

Embodiment 2

[0034] The low-pressure casting machine of the present invention includes a frame, a holding furnace installed in the frame, and a main machine matched with the holding furnace; the main machine includes a sand box structure, a molten steel level measuring structure, a guiding mechanism, and a connected power follow-up mechanism; the main engine also includes a hydraulic cylinder connecting plate, a furnace body platform and a group of guide rails arranged below the furnace body platform, the holding furnace is arranged on the furnace body platform, and a Rollers that match the rails.

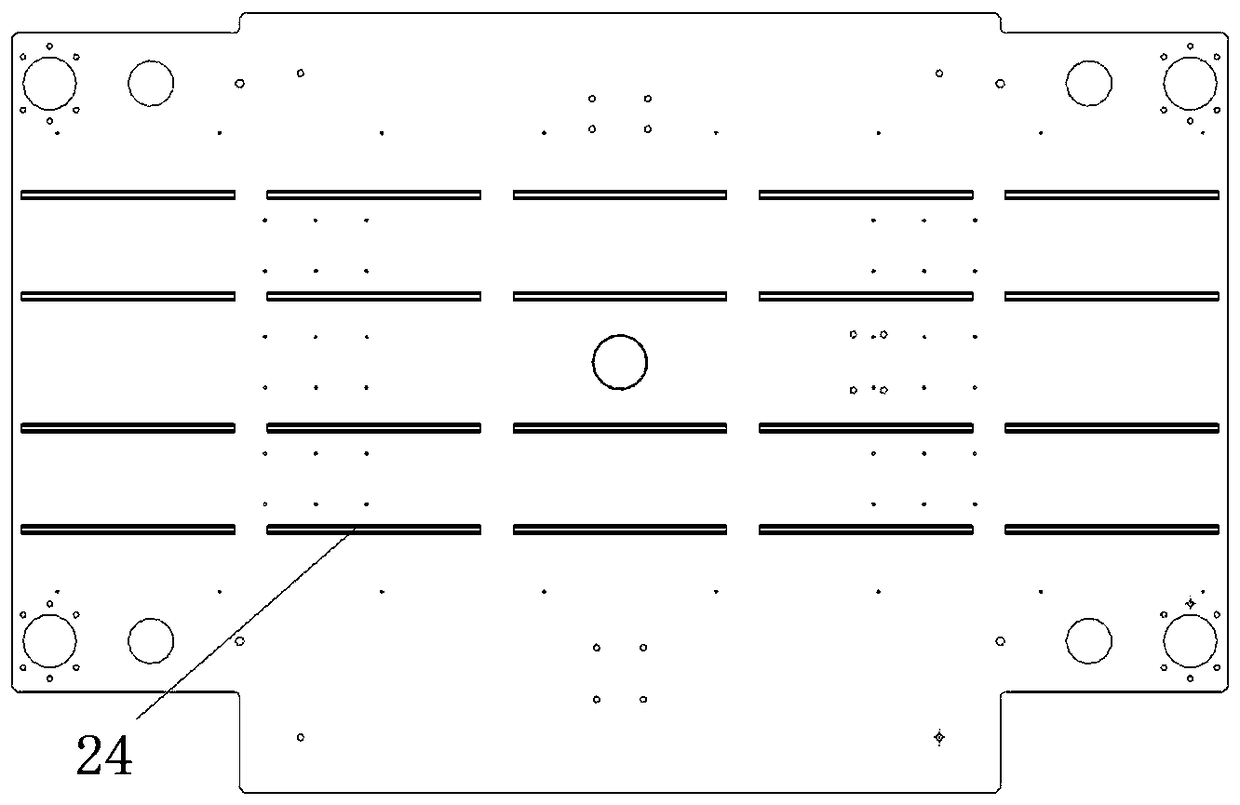

[0035] The track is arranged horizontally to ensure the smooth movement of the furnace platform; the rollers at the bottom of the furnace platform are placed on the guide rails and driven by the hydraulic cylinder C to realize the forward and backward movement of the furnace platform; the sand box platform is equipped with a Sand box positioning mechanism, the positioning mechanism has a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com